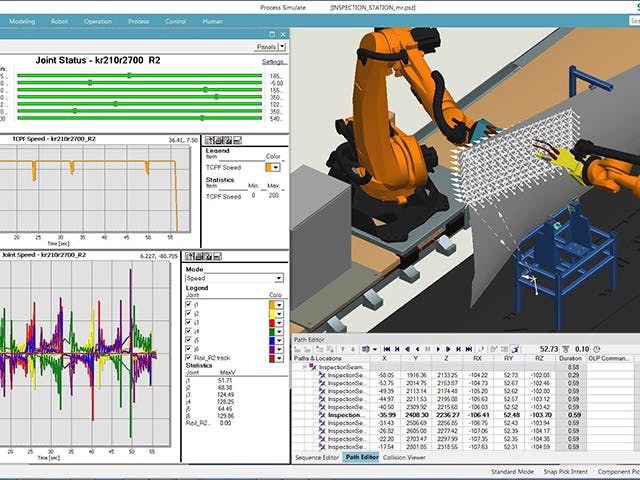

Robotics virtual commissioning uses an automation simulation environment, rather than the physical robotics system, to test the system’s behavior based on the actual control software. Robotics virtual commissioning is performed ahead of production-floor deployment and commissioning. It is one of several functional capabilities of robotics simulation software.

Robotics virtual commissioning employs a digital twin, which is an interactive virtual representation of the robotics system and surrounding production environment, to simulate the robotics system’s planned and programmed operation. It enables manufacturing engineers to perform offline robotics programming and test it without disrupting current production operations.

Robotics virtual commissioning uses an automation simulation environment, rather than the physical robotics system, to test the system’s behavior before production-floor deployment and commissioning based on the actual control software. It is one of several functional capabilities of robotics simulation software.

Related products: Tecnomatix Process Simulate