Robotics simulation is a digital tool used to engineer robotics-based automated production systems. Functionally, robotics simulation uses digital representation – a digital twin – to enable dynamic interaction with robotics models in a virtual environment. Robotics and automation simulation systems aim to bring automation systems online faster and launch production with fewer errors than conventional automation engineering.

Automation simulation plays a crucial role in robotics because it permits experimentation that is expensive and time-consuming to perform on actual robots – and even more so to conduct experimentation on the production floor. Robotics simulation allows engineers to try ideas and construct manufacturing scenarios in a dynamic virtual environment, collecting virtual response data that accurately represents the physical responses of the control system.

Robotics simulation has steadily evolved to keep up with the growing capabilities of industrial robots. Robots are being deployed into dynamic environments where the robot's tasks change frequently or involve human collaborators. Demand for advanced robotics continues to grow as manufacturers increase product complexity, variety and customization to meet customer demand. Advanced robotics incorporates runtime decision-making, reactive programming for unforeseen events, and the ability to adapt and improve based on data collected by the industrial internet of things (IIoT) processed with artificial intelligence (AI). The level of complexity in advanced robotics programming and deploying and operating advanced robots, as well as the high cost that would be incurred to debug a robotics system on the production floor, make advanced robotics simulation a critical component of manufacturing engineering.

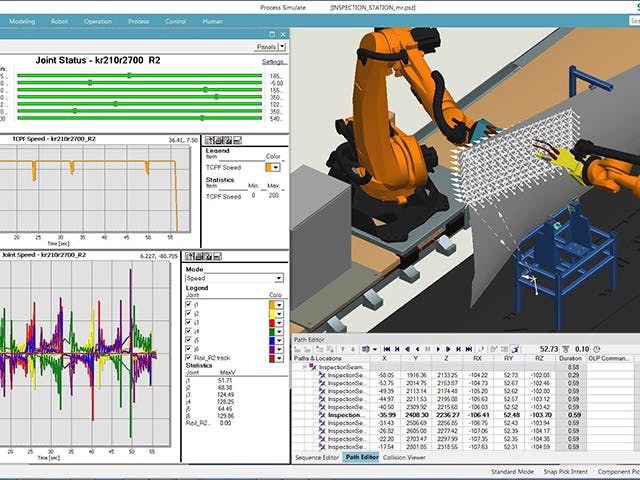

Advanced robotics simulation software enables users to engineer and optimize robotic production, which comprises the new flexibility and customization made possible by advanced robotics technologies. Engineers may employ advanced robotics simulation to design complete 3D robotic work cells, then validate and optimize manufacturing process sequences simulating realistic behavior and responses. They can validate automation concepts digitally and perform offline advanced robotics programming. This simulation software also allows companies to commission complete production systems virtually.

Related products: Robotics Planning & Simulation | Tecnomatix Process Simulate