Lights-out factories, and more commonly, lights-out manufacturing cells, are possible today because of the development and maturity of numerous automated machines and robots and comprehensive and proven manufacturing operations management (MOM) software. Most automated systems can perform tasks with no human intervention. MOM software can orchestrate fully automated manufacturing processes. This software also provides visibility into autonomous production processes. Human stakeholders can remotely oversee lights-out operations and receive alerts to perform complementary activities or interventions.

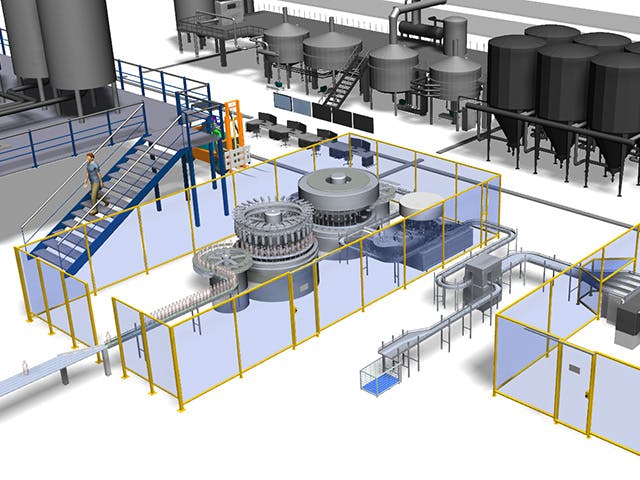

The lights-out factory is easily implemented for simple mass production of a standard product on a fixed schedule. A completely dark factory becomes more difficult (though not impossible) as products grow in complexity and mass customization creates many product variants. Manufacturers experiencing these trends may benefit from a "lights-sparse" factory floor, where lights-out manufacturing is confined to specific operations and areas. In this way, many manufacturers could gain the advantages of autonomous production without completely transitioning to a full lights-out factory.

Related products: Opcenter | Tecnomatix