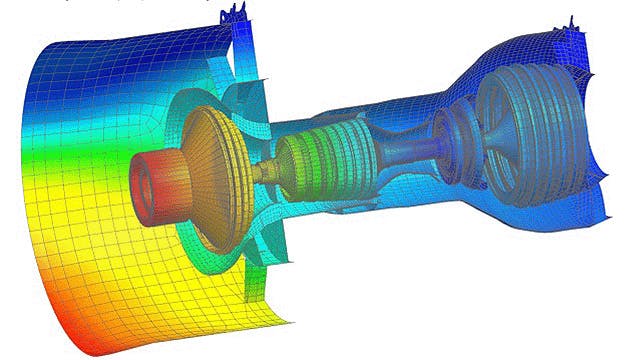

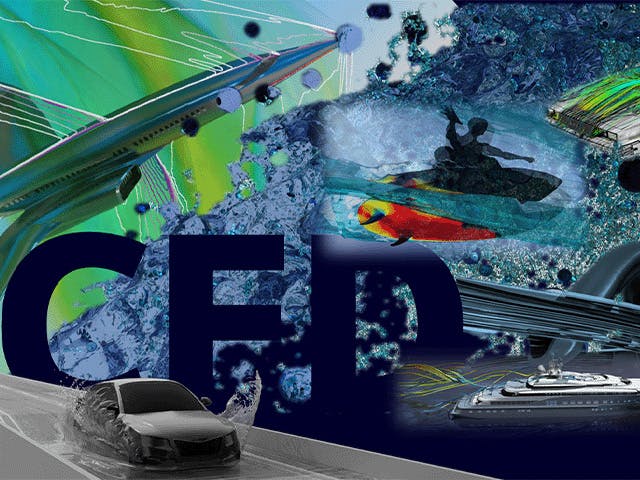

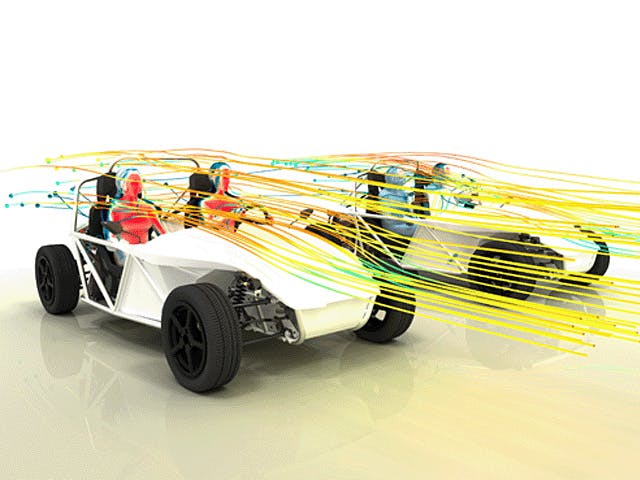

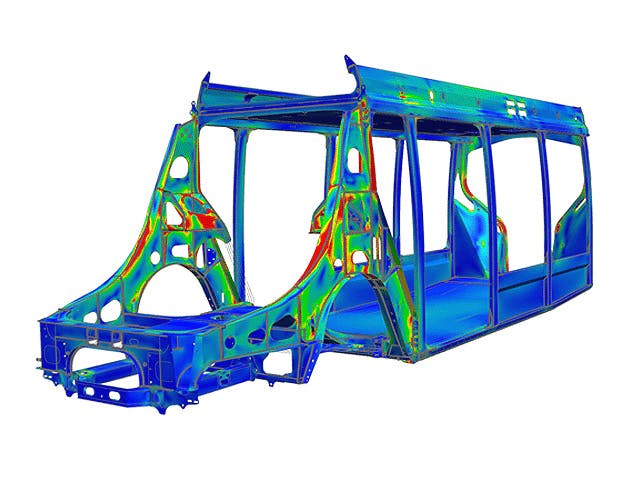

CAE or computer-aided engineering is the use of computer software across a wide range of industries to simulate physics-based performance to improve product designs or assist in the resolution of engineering problems. This includes simulation, validation and optimization of products, processes and manufacturing tools.

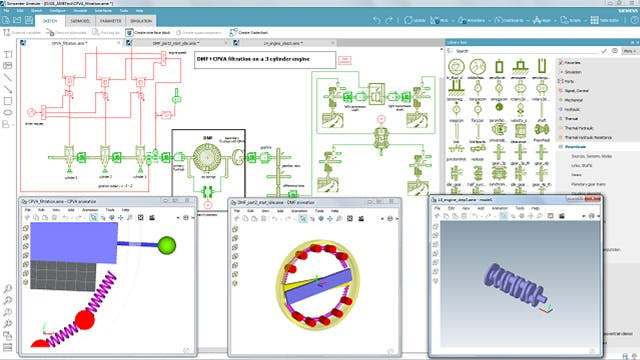

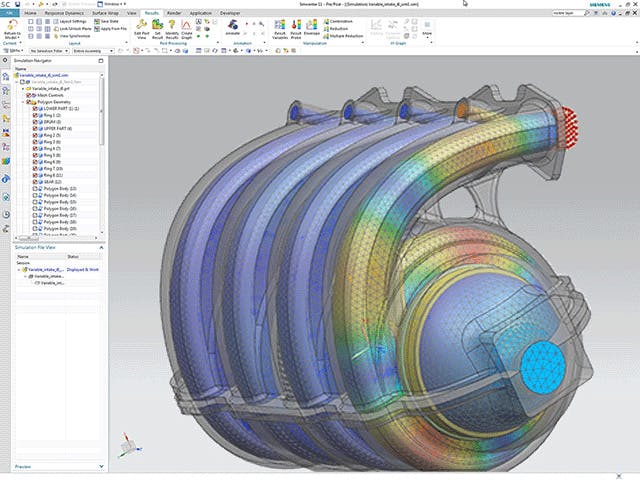

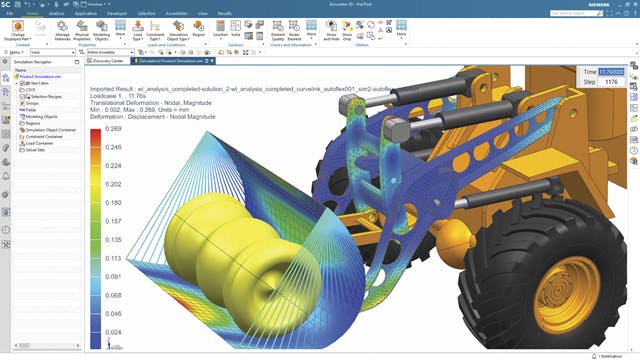

A typical CAE process comprises preprocessing, solving and postprocessing steps. In the preprocessing phase, engineers model the geometry (or a system representation) and the physical properties of the design, as well as the environment, in the form of applied loads or constraints. Next, the model is solved using an appropriate mathematical formulation of the underlying physics. In the postprocessing phase, the results are presented to the engineer for review.

Related products: Simcenter 3D | Simcenter Nastran | Simcenter Femap | Simcenter MAGNET | Simcenter E-Machine Design | Simcenter STAR-CCM+ | Simcenter FLOEFD for NX | Simcenter Flotherm XT | Simcenter Madymo | Simcenter Amesim