Fibersim enables part-specific design approaches for advanced composite structures. These approaches are specialized depending on the industry, whether automotive, aerospace, energy, or others where composites play a role.

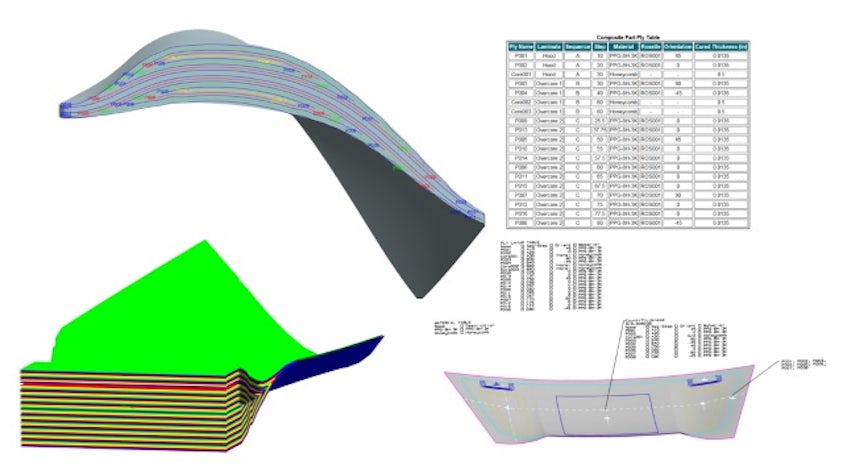

To be fully optimized, advanced composite parts require unique analysis, design and manufacturing workflows. Fibersim leads the industry in supporting specialized workflows for the development of advanced composites. It supports concurrent engineering where analysis and design are performed in the context of the manufacturing, which is key to developing the highest performance, lowest cost designs.

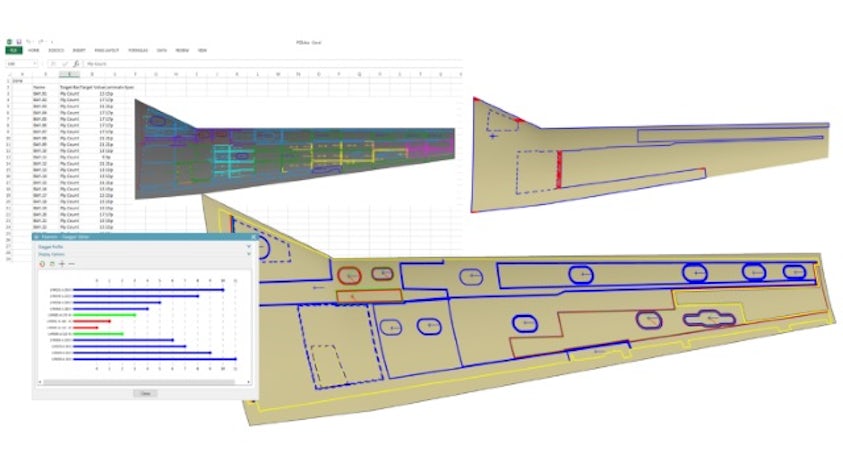

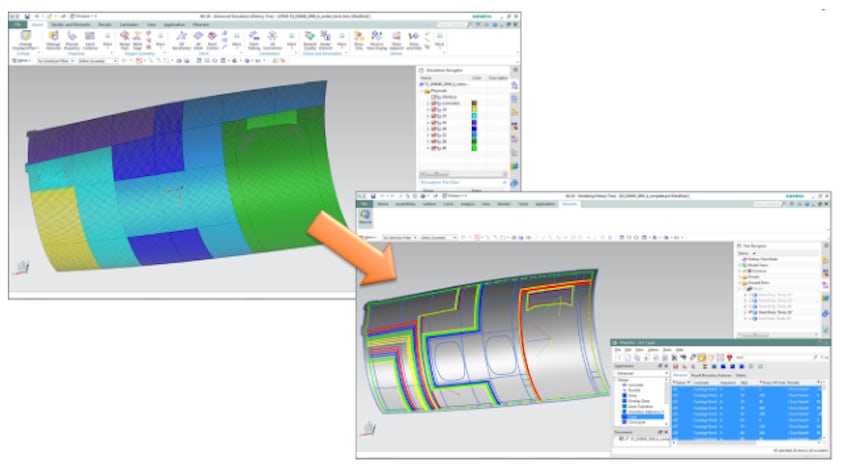

Advanced composites undergo extensive analysis and design iterations carefully considering a part’s unique weight implications. Fibersim features tight integration with Simcenter and other CAE systems, providing bi-directional updates between designers and analysts while taking manufacturing constraints into consideration.

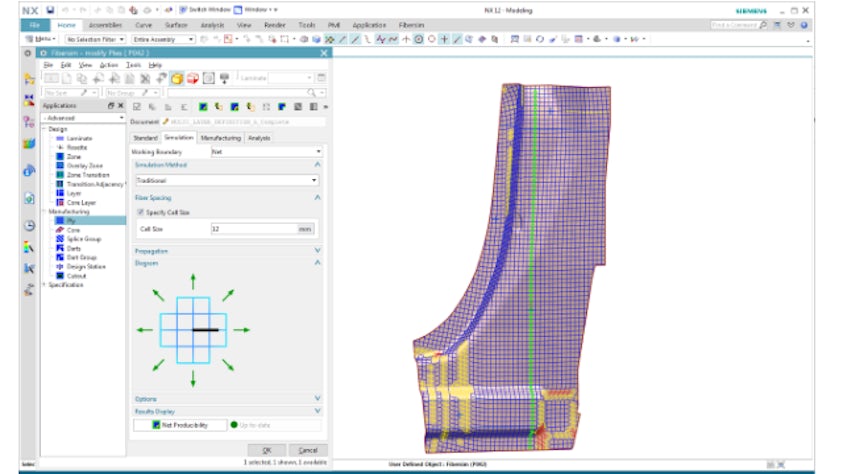

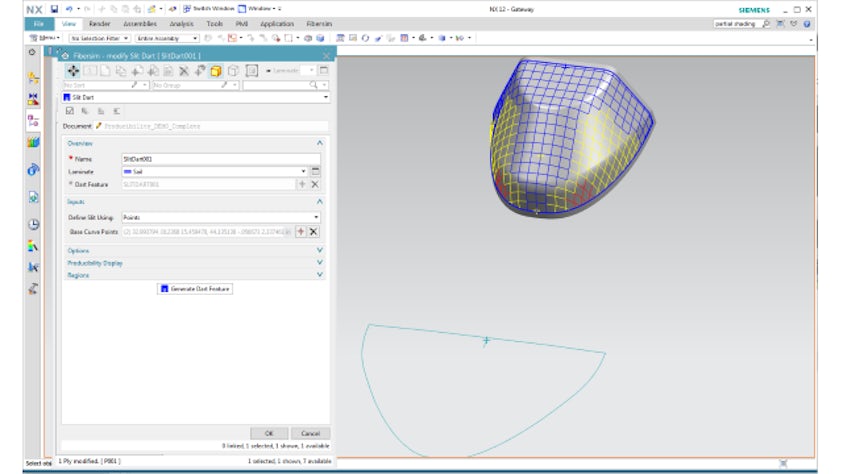

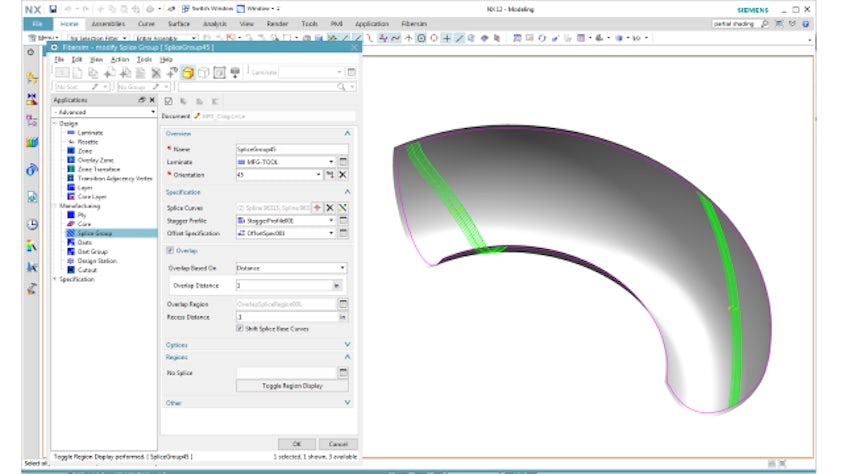

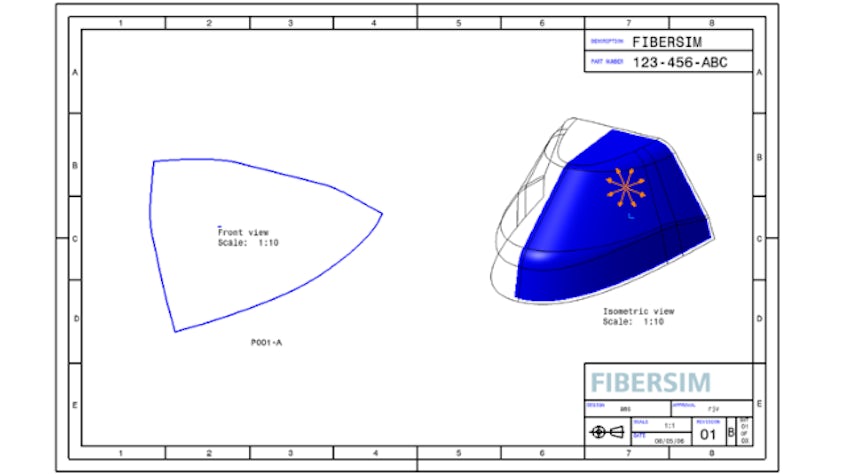

Design for advanced composite manufacturing is available as well. Whether the manufacturing process is hand laid, tape laid, fiber placed, or braided, Fibersim has the capabilities to ensure the design is fully manufacturable before design release.

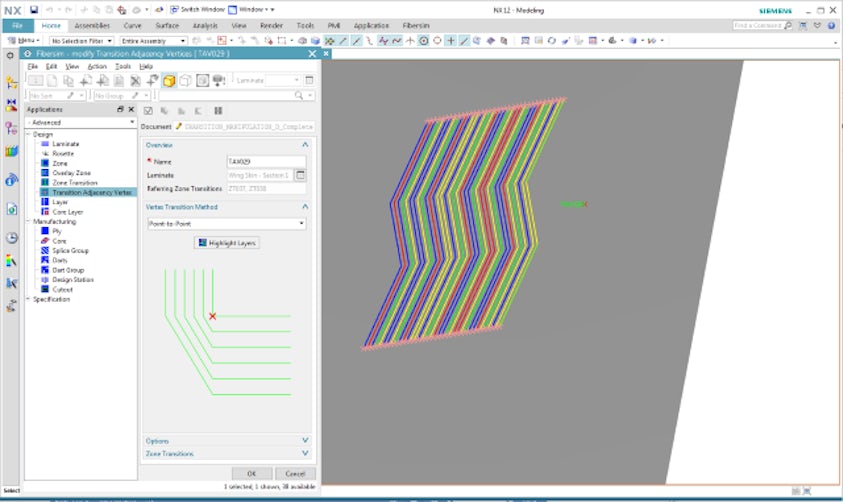

The open, multi-CAD architecture of Fibersim provides these specialized engineering capabilities in NX, CATIA and CREO. Fibersim also saves the detailed laminate structure of the composite design into Teamcenter to share across the enterprise.