Global pioneer in the manufacture of car-carrier trucks uses Simcenter to reduce CAE model preparation time by 60 percent

Use of Siemens Digital Industries Software technology helps company significantly boost efficiency in its design and analysis process

Lohr

Lohr is a privately-owned French group installed in Alsace close to Strasbourg. For over 50 years, it has been a world specialist in the design and manufacture of transportation systems. Lohr group owns factories in Turkey, China, India, the United States and Mexico.

http://lohr.fr/- Headquarters:

- Strasbourg, France

- Products:

- Samcef Desktop, Simcenter 3D Software, Simcenter Products

- Industry Sector:

- Automotive & transportation

The key differentiator of Simcenter 3D is the strong CAD to CAE associativity, which allows automatic CAE model generation based on the CAD model. We can realize a huge improvement of our work methodology thanks to the integration of the design and simulation tools in our development process, allowing up to 60 percent reduction in time for CAE model preparation.

LOHR

About Lohr

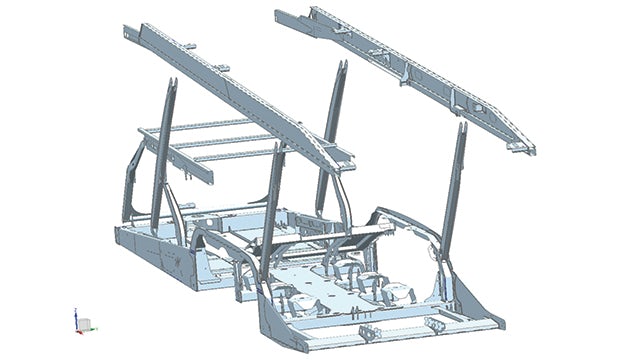

Specializing in design and manufacturing of transportation systems for goods and people, Lohr is the world leader for transport of vehicles, with car-carrier trucks, semi-trailer rail transportation systems, and electro-mechanical solutions. A global company, Lohr employs a staff of more than 2,000 worldwide, with eight factories on three continents and more than 120 engineers and technologists at its research and development center in Strasbourg.

Maintaining a leadership position

The design, manufacture and marketing of equipment for vehicle transportation have been essential activities at Lohr for more than 40 years. Lohr’s major concerns include improving safety and ergonomics, while delivering products that accommodate the constant evolution of the vehicles carried by their customers. To serve this market, Lohr offers a broad range of car-carriers of the highest quality, enabling transporters to optimize service with flexibility that complies with all regulations.

To maintain its leadership position, the company relies on innovative, state-of-theart technologies to meet the needs of modern car logistics. These include Simcenter™ 3D software for detailed modeling and Simcenter Samcef™ software for linear and advanced nonlinear analysis. Both solutions are from Siemens Digital Industries Software.

“Car-carrier and semi-trailer rail are a competitive advantage for complying with regulations in terms of green energy,” says Didier Turlier, structural analysis manager at Lohr. “To keep this advantage, Lohr is continuously investing in new transportation system development. To sustain this approach, we rely on advanced and accurate simulation tools, including Simcenter Samcef and Simcenter 3D.”

Gaining deeper insight

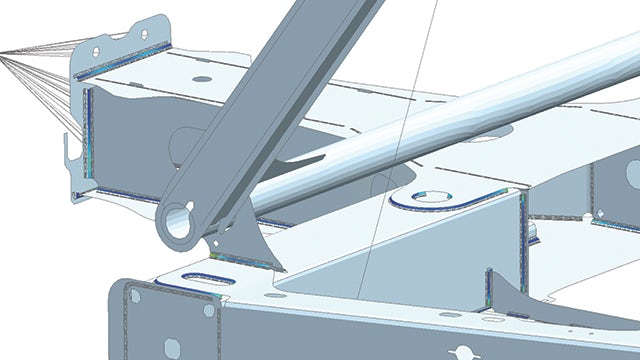

Lohr’s products include heavy vehicle structures that are subject to static and fatigue loads. These are assemblies of sheet metal components joined by bolt fasteners and welds, which challenge the traditional strength analysis approach. Using simulation for structural analysis is a necessity due to design complexity. Lohr’s objective is to solve structural issues, ensure product strength and reduce warranty costs.

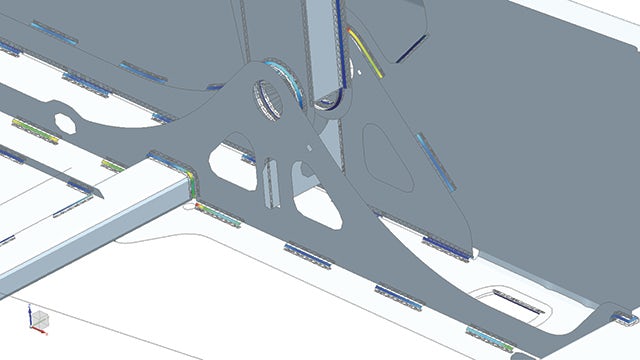

Detailed models of the vehicle structures are created by Lohr’s engineers using the solid modeling capabilities of Simcenter 3D. One challenge is the definition of optimized welds and fasteners, which are fatigue-sensitive. For welds, engineers must take into account weld static calculations and weld toe and root fatigue. For bolted assemblies, engineers must consider such factors as contact with friction, the sliding plan and the validation of technical strength based on physical tests of the structure.

Finite element analysis (FEA) is required to simulate static and fatigue loads for bolted assemblies and continuous welds. Lohr uses the Simcenter Samcef solver family to perform linear and advanced non-linear analysis. “To gain better insight of the structure behavior, we are using Simcenter Samcef for the reliability of its non-linear analyses and for the quality of the support team,” says Turlier.

The solvers enable large structure analysis of detailed models, and provide accurate fatigue results in critical locations. Associativity between the Simcenter 3D model and the finite element model enables faster and easier evaluation of design variations.

Investing in new development process

Lohr is using a dedicated postprocessing tool that was developed using the NX Open application programming interface (API). The company used the API to build a custom program in which the results files obtained using Simcenter Samcef could be used directly by the standard postprocessing functions of Simcenter 3D. With the custom program, Lohr implemented an efficient design and analysis process that effectively integrates the software.

“The combination of the Simcenter Samcef finite element solver, with its advanced nonlinear features, and the comprehensive pre- and postprocessing solution of Simcenter 3D, is a best-in-class simulation tool,” says Turlier. “With more and more requests for detailed analysis, this integrated CAD and CAE environment increases efficiency.”

Reducing CAE modeling time

Integrated design and simulation is helping Lohr achieve its objective to bring higher-quality products to market at lower costs. “The key differentiator of Simcenter 3D is the strong CAD to CAE associativity, which allows automatic CAE model generation based on the CAD model,” says Turlier. “We can realize a huge improvement of our work methodology thanks to the integration of the design and simulation tools in our development process, allowing up to 60 percent reduction in time for CAE model preparation.”

Car-carrier and semi-trailer rail are a competitive advantage for complying with regulations in terms of green energy... To sustain this approach, we rely on advanced and accurate simulation tools, including Simcenter Samcef and Simcenter 3D.

LOHR