Build smart machines with advanced machine engineering

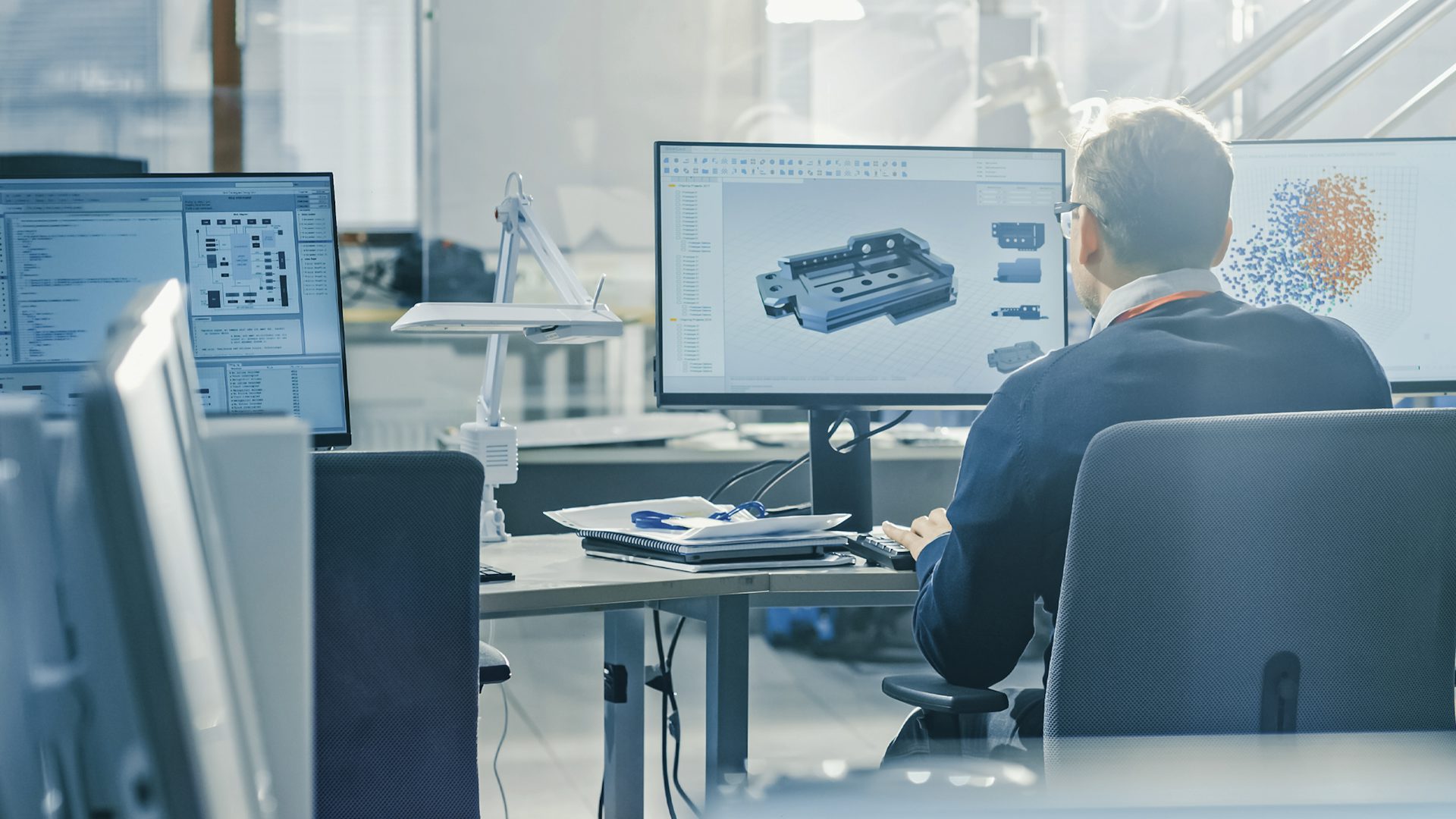

Today's machine builders are challenged to produce highly tailored, smart machines within a short timeline. Advanced machine engineering solutions from Siemens leverage next-generation design software, a digital twin for machine design and integrated digital tools to ensure the effective delivery of projects on time.

Embrace the future of advanced machine design

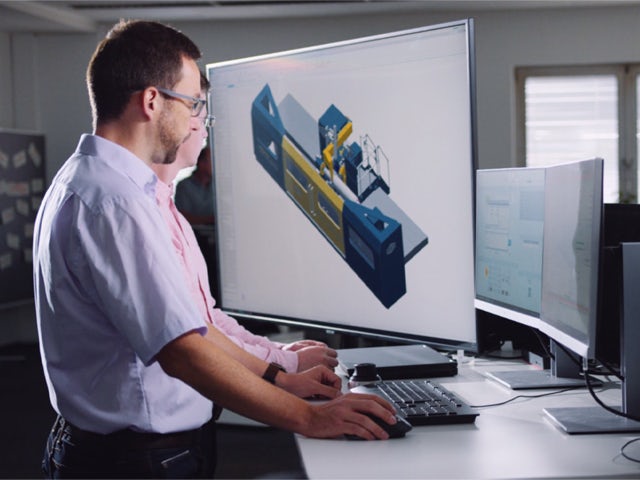

It's time for machine builders to digitally transform their work processes, so they can begin rapidly producing the smart, connected machines their customers expect.

Shorter design phase

Accelerate time-to-market with collaborative design that connect domains at any time, from anywhere. (Tronrud Engineering)

More productive machines

Design and build machines with higher outputs while simultaneously reducing noise, vibration and energy consumption by using simulation early in the design process. (Picanol)

Faster product technical information retrieval time

Manage and share product information in a single location that supports searching and browsing, so less time is spent on CAD data management. (Biesse Group)

Improve your machine design process

Gain greater certainty in the development of next generation machines. Advanced machine engineering accelerates the design process and certifies machine performance by leveraging the digital twin for design, development and commissioning.

Manage product and project requirements information in a single location, resulting in better collaboration and easy design reuse. Machine builders and OEMs increase productivity while gaining visibility on progress without any additional overhead.

- Integrate project management and requirements management with design

- Align on-location and remote workers in a collaborative environment

- Ensure all team members have access to the information needed to do their jobs

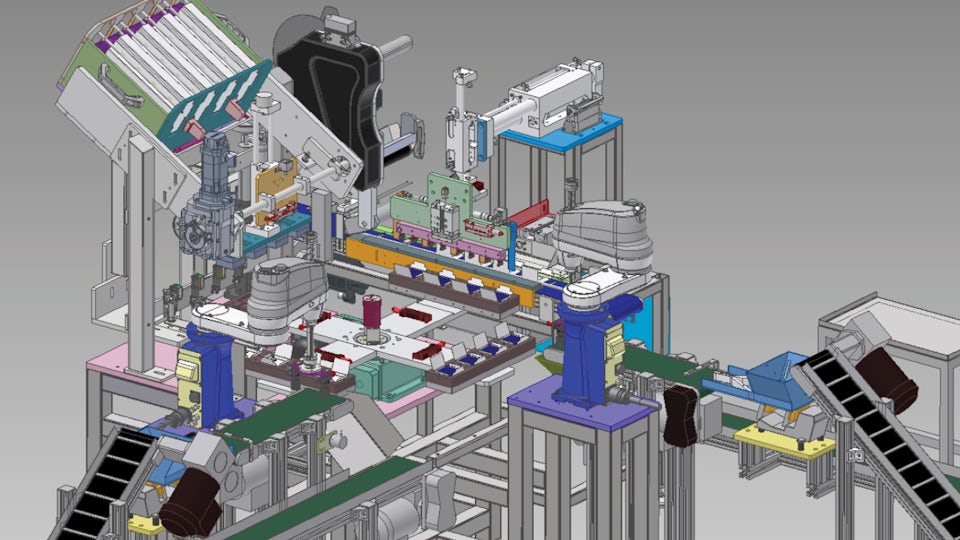

Create the most comprehensive digital twin containing mechanical, electrical, software and automation information. Improve how you quote, design, produce, install and commission more complex, smart, connected and flexible machines than ever before.

- Simulate designs to produce high-performance, energy-efficient machines

- Perform multi-disciplinary analysis without costly physical prototypes

- Eliminate errors with a single, updated virtual mockup of the machine

Take a collaborative, multi-disciplinary approach to design and ensure all customer requirements and industry regulations are met quickly and efficiently. Create an environment compatible with modular design for faster bid response times.

- Integrate engineering disciplines to rapidly deliver highly complex machines

- Use virtual commissioning to verify designs in the first stages of development

- Enable project data to be reused, updated and scaled for mass customization orders

Machine builders using Siemens' solutions can achieve:

Faster collaboration

An integrated solution that rapidly connects remote and in-person workers, driving alignment and streamlining design changes. (Schlatter)

Fewer prototypes

Improve machine accuracy with design simulations in Simcenter, saving time and resources while reducing the need for physical prototyping. (Ronchi Mario)

Shorter lead times

Accelerate the machine building process from start to finish through consistent, automated workflows that simplify decision-making. (Anger Machining)

Solu-Tech

Solu-Tech designs and virtually tests machines with Siemens solutions.

Solu-Tech designs and virtually test machines and production lines with Siemens Digital Industries Software solutions

Company:Solu-Tech

Industry:Industrial machinery

Location:Rosheim, Alsace, France

Siemens Software:NX, Solid Edge

Thanks to the digital twin of our machines, design choices can be made more quickly, and communication between the teams is much more fluid. We spend the time gained on design to virtually validate our installation before its commissioning with the customer.

Explore our resource library

Start building the next generation of smart, connected industrial machines using advanced machine engineering.

Uncover the benefits

Digital twins offer a powerful framework for gaining insights, optimizing performance and driving innovation across various industries by bridging the gap between the physical and digital worlds.

Product lifecycle management

Comprehensive automated design

Machine automation engineering

Performance engineering

Low-code application development

E/E systems development

Frequently asked questions

How can advanced machine engineering improve the manufacturing process?

Advanced machine engineering equips businesses with next generation design tools, a closed loop digital twin and integrated project delivery solutions. Through these three focus areas, firms can eliminate silos, validate sooner and deliver more orders than before.

How does advanced machine engineering contribute to sustainability and efficiency in manufacturing?

With advanced machine engineering's simulation capabilities, businesses can visualize a machine's energy use and scrap output in the digital twin. In turn, designers can fine-tune a machine before it's produced, helping to sustainably optimize its design.

How is advanced machine engineering shaping industry 4.0?

Advanced machine engineering is shaping industry 4.0 by helping more businesses digitally transform. Technological tools that connect data, depict visualizations and deliver products faster are necessary for surviving in today's competitive landscape.

What is machine design engineering?

Machine design engineering, or the way engineers design, manufacture and commission machines, is always evolving. Next-generation machine design integrates mechanical, electrical, electronic and software disciplines into a single design process. Through this collaboration, businesses realize a modular approach to machine design.

How can machine design affect the cost of production?

Machine design directly impacts the bottom line of production. Design for manufacturing (DFM) is the engineering practice of meeting design requirements while optimizing manufacturing ease and lowering production costs. From choosing the right component, part or material to efficient cable routing, each design decision directly affects production's bottom line. Machine builders that design for manufacturability can consistently deliver cost-effective, high-quality products more quickly than their competitors.

What is the best software for machine design?

NX, a part of the Siemens Xcelerator portfolio, provides machine builders with next generation design tools. By integrating disciplines under one cohesive umbrella, greater alignment can be realized. In turn, machines can be visualized and validated sooner, leading to faster delivery of projects.

Watch

Video | Lead the way with Advanced Machine Engineering

On-demand webinar | Start building next-generation machines

Video | STiMA optimizes production with Siemens solutions

Listen

Podcast | Teamcenter X SaaS solutions in the cloud

Podcast | A secure cloud infrastructure with Teamcenter X and AWS

Podcast | PLM for Machine Builders addresses ETO and CTO challenges

Read

Ebook | Accelerate machine design with digitalization

Ebook | An integrated approach to machine design and more

White Paper | Technological innovations drive change for machine builders