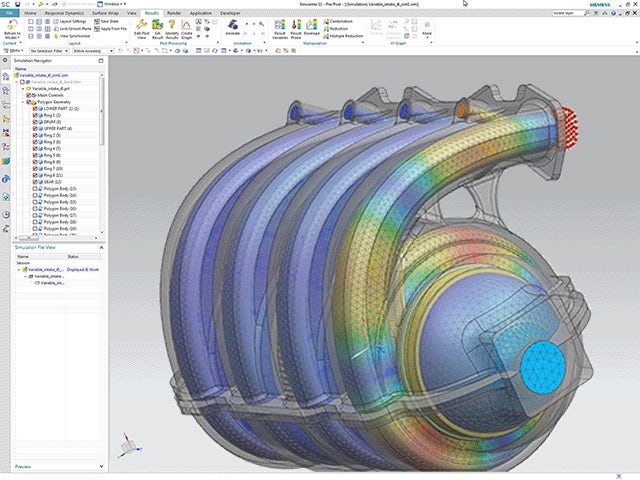

Understanding and delivering cross-domain performance requires simulation and test solutions that can be deployed across all the development phases and across all performance domains and physics. Furthermore, these activities need to be linked not conducted independently to capture real-world multiphysics phenomena and balance conflicting attributes. Simcenter offers an integrated portfolio of best-in-class predictive simulation, test and design exploration solutions that span all phases of the product development process to solve the toughest problems in engineering can help transform engineering by driving productivity and empowering innovation.

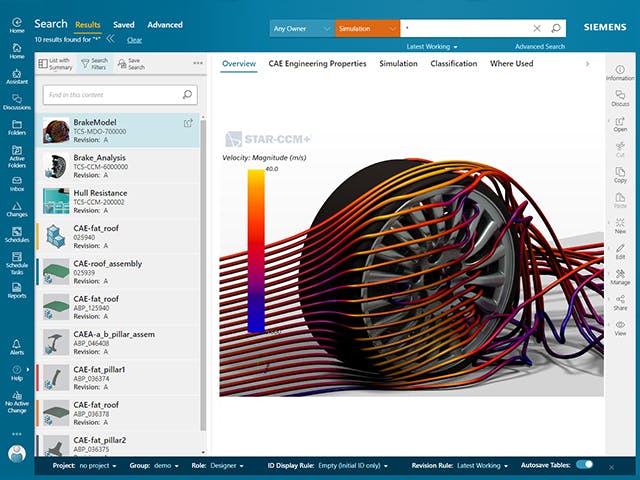

Simulation and testing can no longer be viewed as a siloed activities. The digital twin delivers value across the lifecycle and its evolution needs to be managed for traceability and impact of change. This is only possible by delivering simulation and test as part of an overall digital product development initiative. Siemens Xcelerator blurs the boundaries between engineering domains such as electrical, mechanical and software and Simcenter simulation and test solutions complement Siemens Xcelerator solutions in the design, realize and optimize phases of the lifecycle.

On the journey to digital transformation, companies need reliable partners with the resources to continuously drive innovation in the tools and applications. Siemens spends significantly on research and development, leverages partnerships with established companies in adjacent areas and invests in startups that have the technologies that could transform business in the future. All of this ensures a steady stream of innovations that can help our customers stay on the cutting edge and realize the benefits of digitalization faster than their competitors. Simcenter engineering and consulting services provide deep domain knowledge, facilities, resources and expertise to accelerate engineering process transformation and resulting return on investments.