Solutions for industrializing additive manufacturing

Siemens' robust portfolio of software allows you to execute the entire additive manufacturing process from design to production. Read below to learn what it takes to industrialize additive manufacturing.

Design for additive manufacturing

The beginning of a quality additive manufacturing process is always in the design. AM provides the ability to manufacture highly complex designs with features like optimized surfaces and lattice structures. Our additive manufacturing solutions allow you to design and print complex geometries at scale.

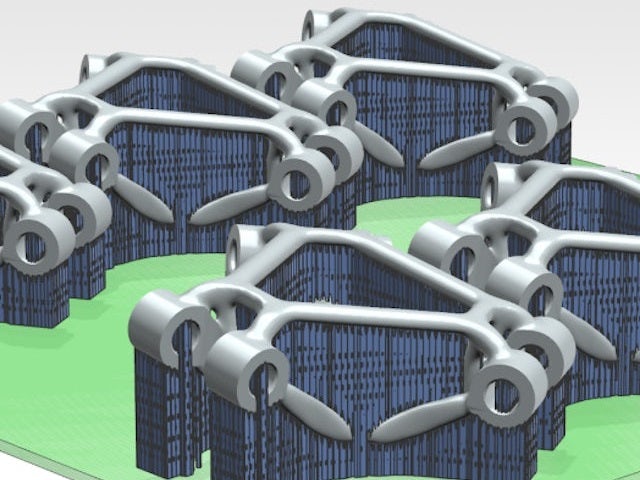

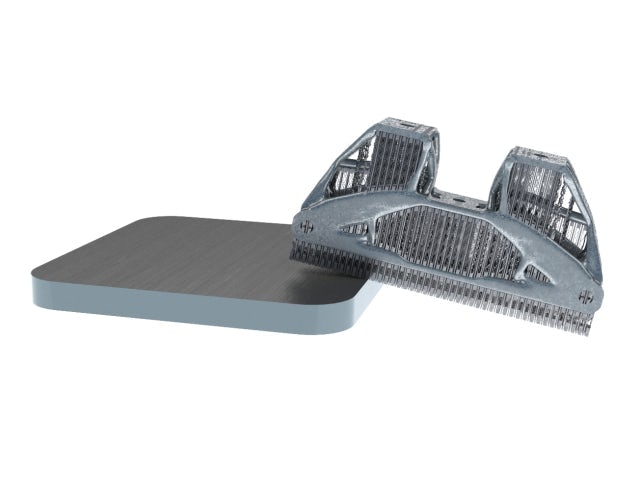

Print build preparation

Quality, efficient output from the AM process requires the proper setup. The integrated build preparation tools in NX assist with placing, orienting and supporting parts in the build tray in the most efficient manner possible.

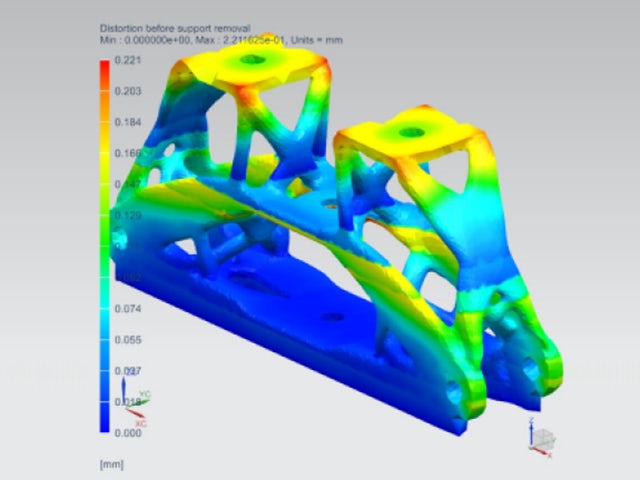

Build simulation

Simulation of the build process can help you generate quality 3D prints at scale. From build orientation optimization to mesoscale deposition path optimization, NX gives you the tools to print successfully the first time.

Machine connectivity

Connect to the widest range of 3D printing hardware with Siemens NX. Some of the systems covered include planar powder bed systems, filament deposition systems, multi-material systems and multi-axis systems.

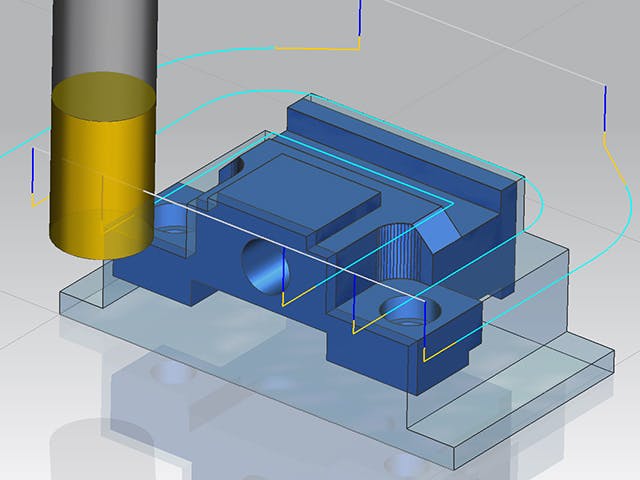

Post-print processing

Industrialized 3D printing requires robust post-processing software. Printing is not the last step in the additive manufacturing process. Powder removal, removal of the part from the build tray, and post-process machining are all aspects of the full AM process—and all are part of our additive manufacturing solution set.

Process management

To maximize the efficiency of additive manufacturing production, the process must be well managed. This includes the order-to-shipment process, but also the management of materials and machine scheduling. We offer solutions for companies of all sizes to help ensure maximum efficiency of the complete AM process, thereby maximizing the ROI from your additive manufacturing investment.

LimaCorporate

Designing 3D printed implants with NX

Company:LimaCorporate

Location:Villanova, San Daniele del Friuli, Italy

Siemens Software:NX

Size:Medium

Explore related NX for AM products

View our professional solutions for pragmatic, industrial additive manufacturing design.