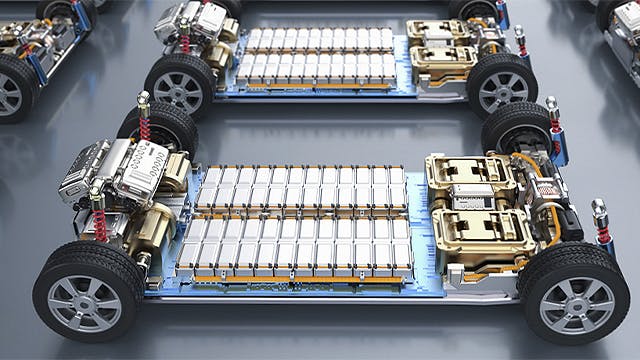

Vehicle performance relates to the overall capabilities, efficiency and functionality of a vehicle, encompassing aspects such as acceleration, battery range, safety, aerodynamics and water management, advanced driver-assistance systems (ADAS), energy and thermal management, noise, vibration and harshness (NVH) and acoustics, strength and durability, vehicle controls and vehicle handling.

Automotive performance engineering is driven by business requirements and delivers end-to-end system optimization through a continuous virtual testing and monitoring loop. Using a shift-left strategy, car makers and suppliers aim to provide better business value by discovering potential issues early in the development cycle. By using simulation early in the design process and virtually testing if products meet the requirements, they can detect problems early and rectify them in a comprehensible digital twin. Additionally, they can explore design alternatives earlier in the design phase when changing designs is easier and less disruptive.