What strategies can aerospace engineers employ to accelerate design timelines, achieve performance targets and ensure a smooth introduction into service?

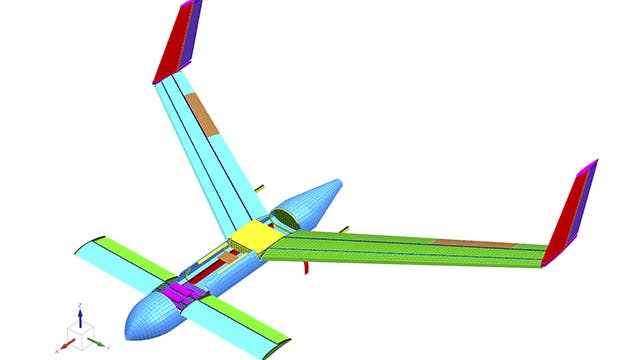

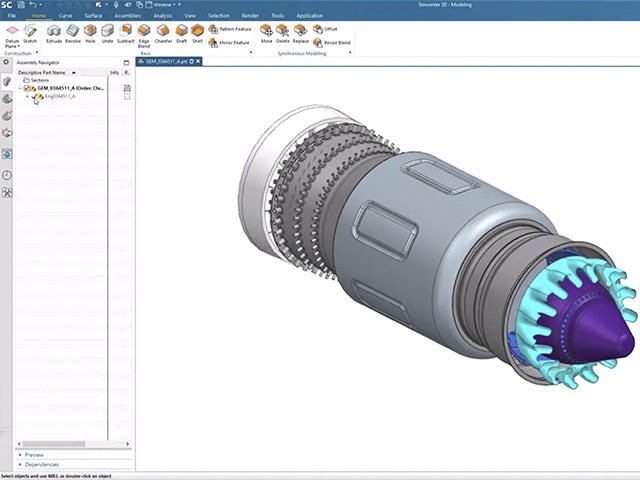

Implement an integrated simulation and test strategy and utilize aerospace simulation software to drive digital transformation, break down silos between disciplines and gain earlier insights into product performance for structures, aerodynamics, virtual integration and beyond.