The next generation of ships must perform more efficiently to meet fuel consumption and emissions regulations. At the same time, they must obey minimum ship power requirements in line with the IMO MEPC guidelines to ensure safe operation in any sea state. Is there a way to directly predict ship/engine interaction? And optimize the engine system performance before the ship launches?

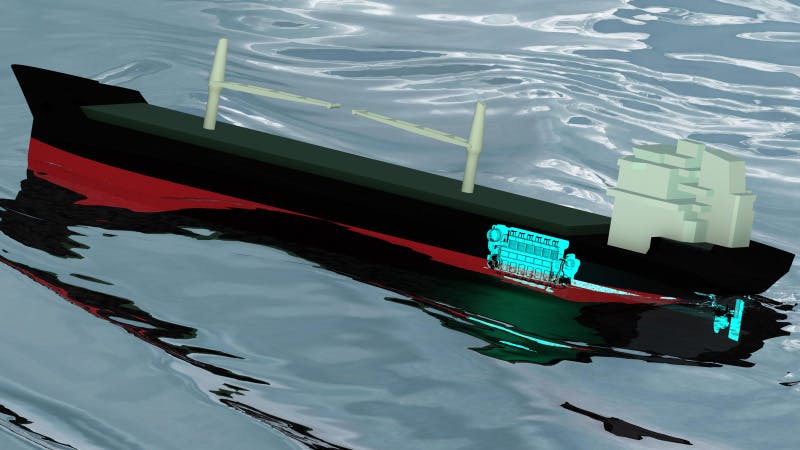

This webinar shows how combining 1D system/control software with 3D marine CFD software creates a digital twin of the complete ship engine system. This approach gives you a detailed understanding of how the hull and engine interact with each other. It will enable you to predict ship fuel consumption and emissions for any sea state. Using the MV Regal as an example, we show how to predict minimum ship power requirements for safe operation in head and beam seas.

Learn the benefits of combining ship hydrodynamics and system simulations

Topics include:

- The benefits of coupling 1D and 3D marine CFD simulations

- How and why to use co-simulation, and examples of when to use different approaches

- How to include control systems and rudder coupling in your performance prediction

- Prediction of ship fuel consumption and emissions in different sea states

- Examples of minimum power prediction in beam seas using the MV Regal

This webinar demonstrates our marine simulation software

It will be of interest to ship design teams, naval architects, and engine design teams who are looking to improve their system efficiency. Existing users of either Simcenter STAR-CCM+ or Simcenter Amesim will find the co-simulation methods of interest. The webinar will be useful to both managers and users of marine simulation software. Anyone interested in the latest software solutions for marine design should watch.

How are companies using co-simulation to improve ship fuel consumption?

Watch this on-demand webinar to hear Wärtsilä Propulsion present their use of connected Simcenter Amesim and Simcenter STAR-CCM+ for propeller system design. By directly linking 1D system simulation and 3D marine CFD, they increased the realism of their propulsion results and found optimal fuel consumption for different operating scenarios.

Create a digital twin of your ship design with our marine simulation software

Our solutions help ship designers to predict multiple aspects of ship performance from early in the design phase to service. A marine CFD simulation can be considered the first step toward a digital twin for performance. But combining this with system simulation builds a better, more detailed digital twin. Your simulations no longer stop at the external propeller, but also include the complete engine system. This coupled approach means you can extract more performance information and gain more detailed insight.

Meet the speakers

Romain Nicolas

Business Developer

Romain is responsible for system simulation activities in the heavy equipment sector. He started his career in 2011 as control systems engineer in the Volvo AB Group. There, he developed a platform for control algorithms verification, led several projects as system responsible, and worked as a software developer using Agile methodology. He has a Mechanical Engineering degree from ESTACA Paris and an MSc from IFP School.

Miles Wheeler

Marine Application Specialist

Miles Wheeler is the current marine application specialist for Siemens Simcenter STAR-CCM+. He holds a Master’s degree in hydrodynamics and composite structures from the University of Washington and is a PhD candidate at Washington State University; where he has been researching flexible hydrofoils and planing hulls. He has been engaged in marine CFD simulations for 15 years and is one of the few people who have used every version of Simcenter STAR-CCM+.