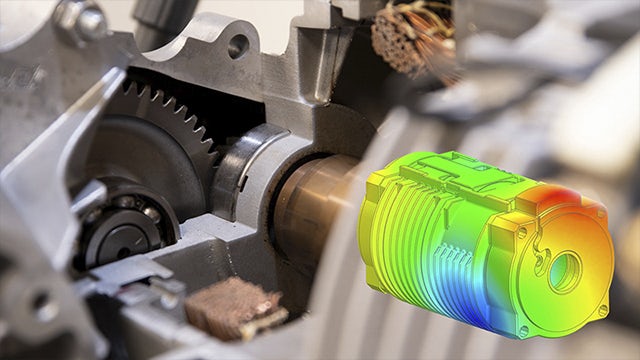

Die aktuellen Vorgaben an die Verkürzung der Markteinführungszeit und der Entwicklungskosten moderner Systeme wirken sich stark auf das Leben von Testingenieuren aus. Die reduzierte Verfügbarkeit von Prototypen und die begrenzte Testzeit stellen die Branche vor die Herausforderung, die Prozesse zur Produktvalidierung immer effizienter zu gestalten. All dies ohne Kompromisse bei Qualität und Vollständigkeit, da noch weitere Testbedingungen und Anwendungen ausgewertet werden müssen, mit hohen Überschneidungen bei den Anforderungen an Instrumentierung, Messung und Analyse.

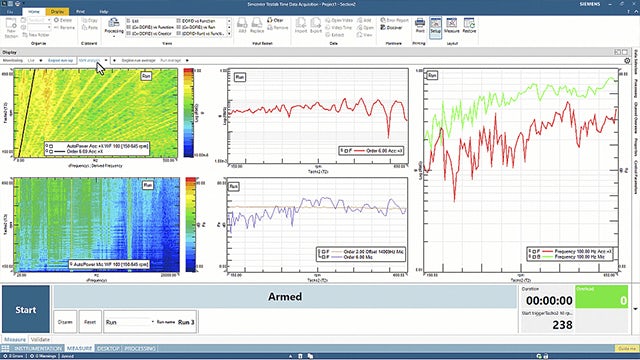

Um NVH-Teams auf diesem Weg zu unterstützen, bietet Simcenter spezielle Lösungen an, mit denen Sie Ihre NVH-Testkampagnen optimal nutzen können, sowohl auf dem Prüfstand als auch in der Praxis: Kombinieren Sie unsere skalierbare Erfassungshardware mit unserer Mess-, Verarbeitungs- und Analysesoftware, um NVH-Bewertungen noch kosteneffizienter zu machen.

Von einfachen Fehlerbehebungsmaßnahmen mit begrenzter Kanalanzahl bis hin zu umfassenden, hochgradig multiphysikalischen Testkampagnen helfen Ihnen unsere Lösungen, das NVH-Verhalten Ihres Produkts in den verschiedenen Phasen des Entwicklungszyklus zu überwachen.

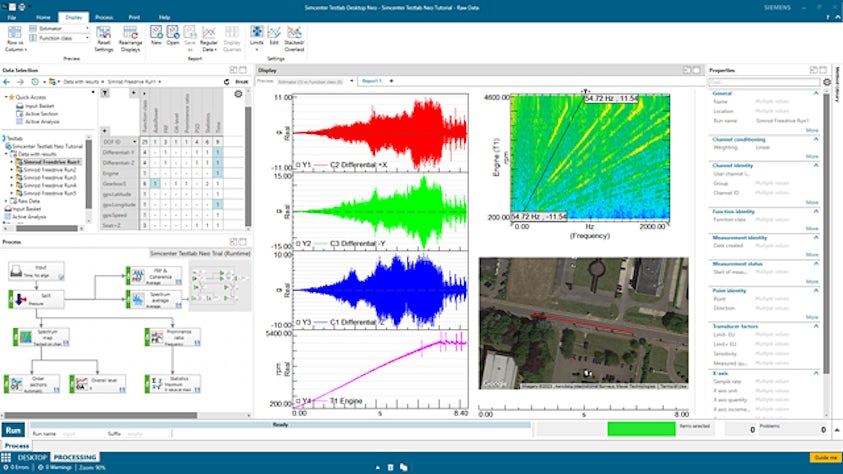

Dafür bieten wir eine breite Palette von Verarbeitungsmethoden an, von schnellen und standardisierten NVH-Metriken bis hin zu Ad-hoc-Analysetechniken wie Klangqualität oder Rotationsdynamik. Unser Ziel ist es, die Produktivität bei jedem Schritt Ihrer Messkampagne zu steigern.

Neueste Innovationen in der NVH-Betriebsprüfung von Fahrzeugen

Erfahren Sie, wie Sie Geräusche und Vibrationen unter Betriebsbedingungen in einem flexiblen Setup schnell beurteilen können. Entdecken Sie, wie Sie in kürzerer Zeit mehr NVH-Informationen erhalten und sich auf die Qualität verlassen können.//Erfahren Sie, wie Sie in kürzester Zeit noch mehr NVH-Informationen erhalten und sich dabei auf die Qualität verlassen können.