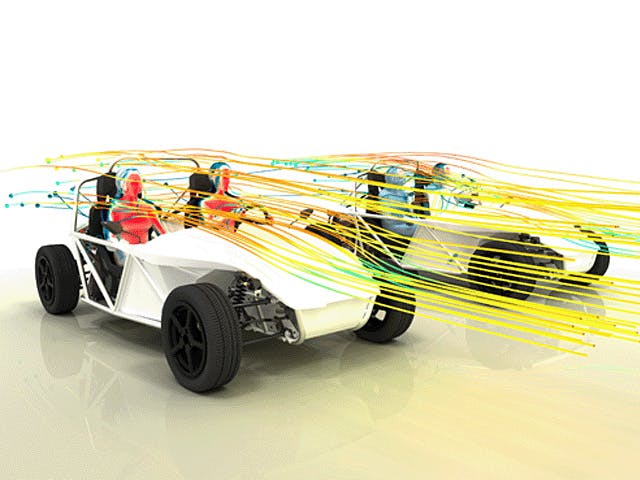

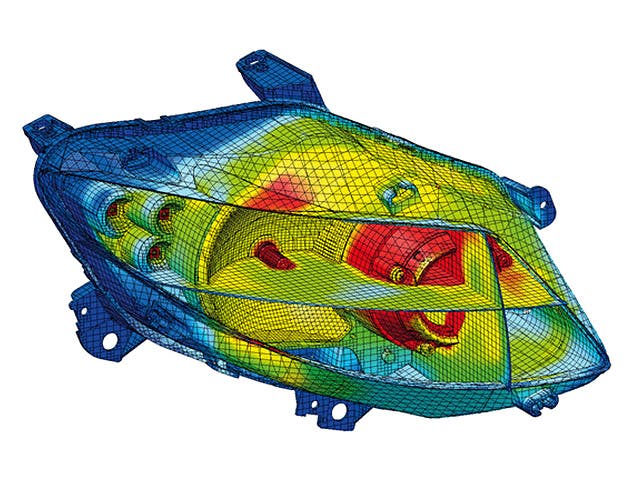

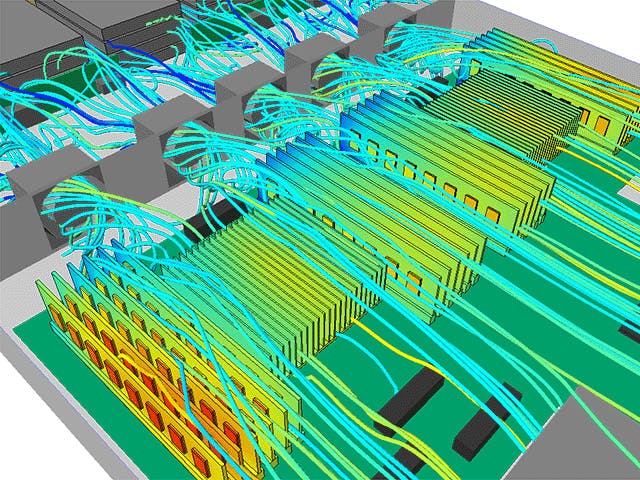

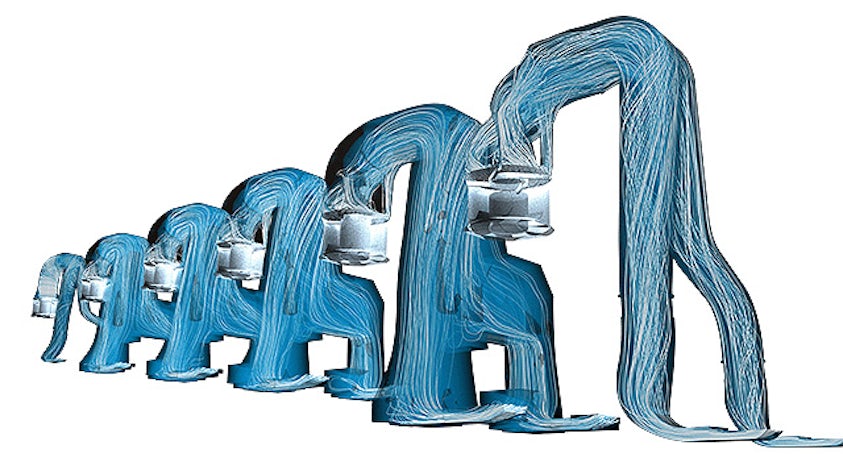

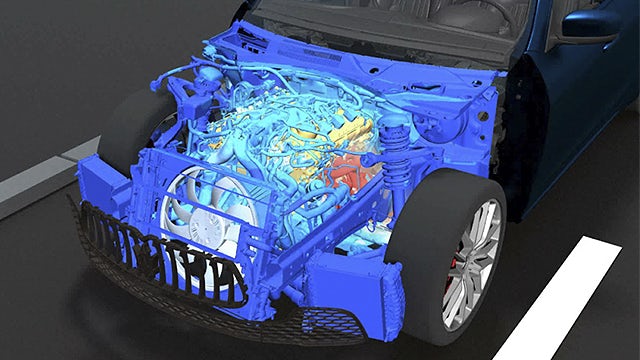

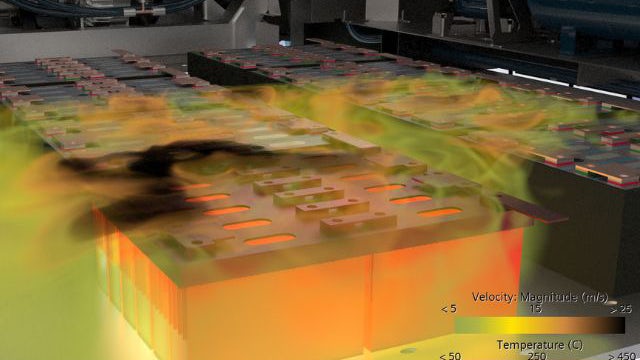

Die reale Leistung vieler Produkte hängt von ihrer Wechselwirkung mit Fluida ab, entweder Gasen, Flüssigkeiten oder einer Kombination aus beidem. Die numerische Strömungssimulation (CFD) bietet die Möglichkeit, das Strömungs- und Wärmeübertragungsverhalten zu simulieren und vorherzusagen. In einer Welt mit immer größerer Produktkomplexität reicht es jedoch nicht mehr aus, die Strömungsdynamik und die Wärmeübertragungsleistung eines Produkts isoliert zu verstehen.

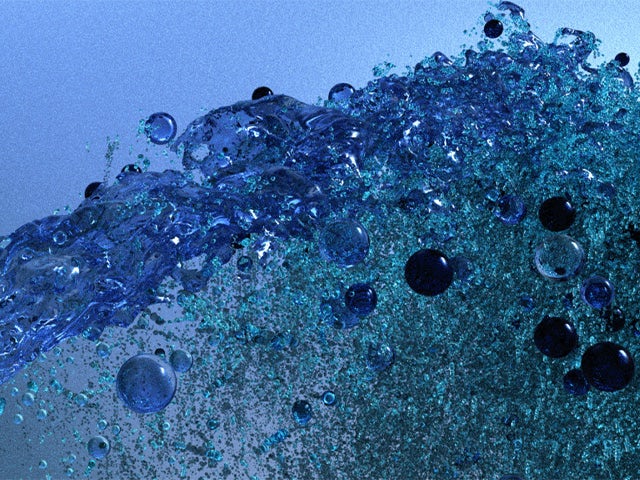

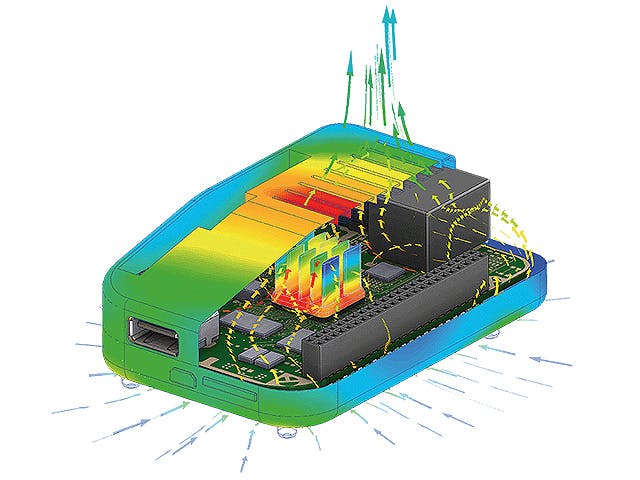

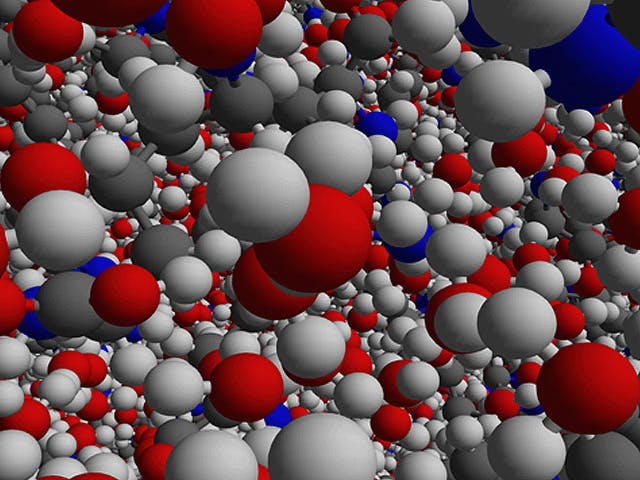

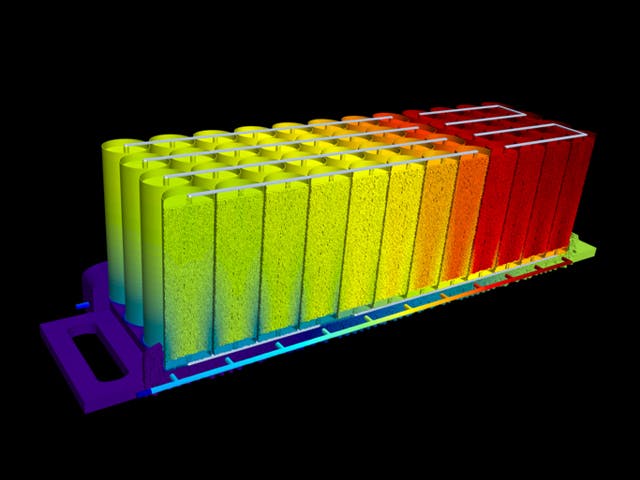

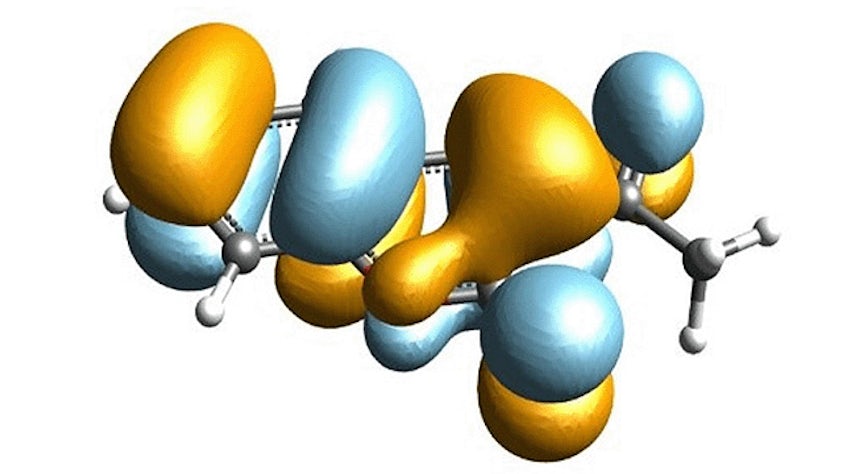

Um die Komplexität in einen Wettbewerbsvorteil zu verwandeln, müssen CFD-Ingenieure von heute in der Lage sein, ein breites Spektrum fluidbezogener Physik zu modellieren, von reagierenden Strömungen bis zur Aeroakustik, von Mehrphasenströmungen bis zur Partikeldynamik, von der Elektronikkühlung bis zur Aerodynamik.

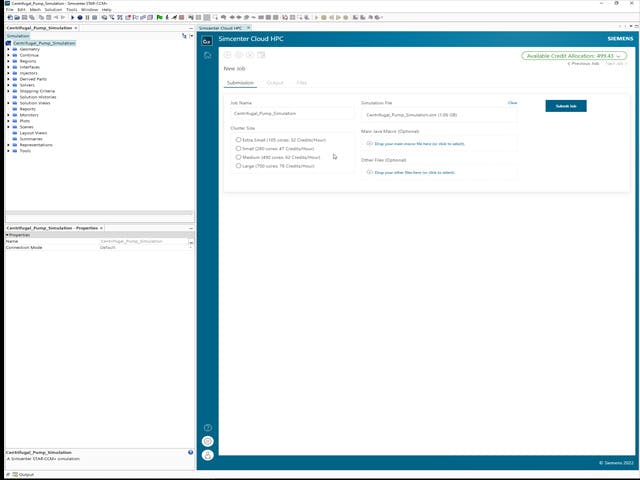

Mit der Fluid- and Wärmetechnik-Simulationssoftware von Simcenter können Sie die komplexesten Probleme der Strömungsdynamik virtuell vorhersagen und Ihre Erkenntnisse in Produktinnovationen umsetzen.