Automatisieren Sie die NC-Programmierung, um die Produktivität zu steigern

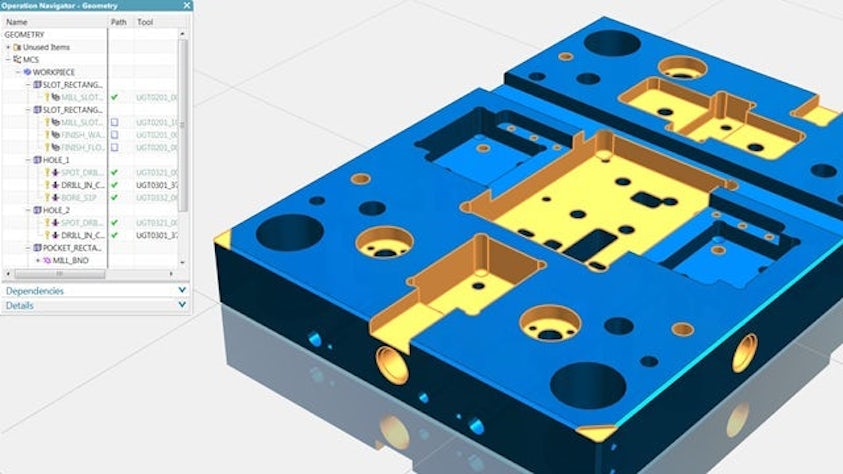

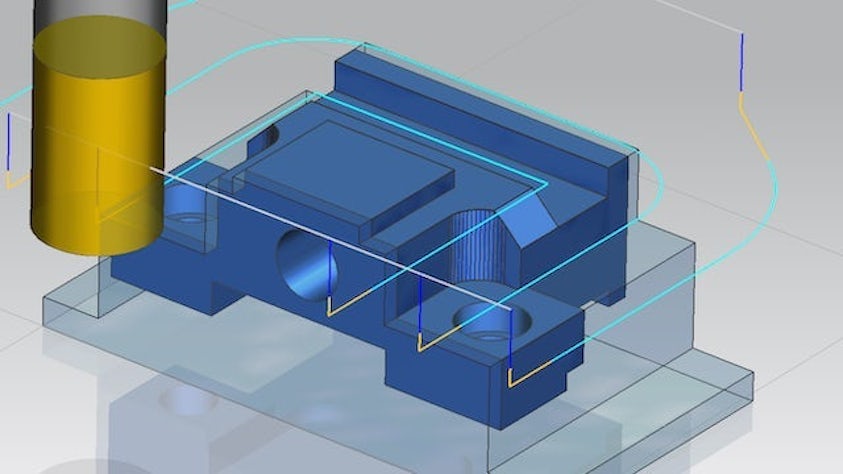

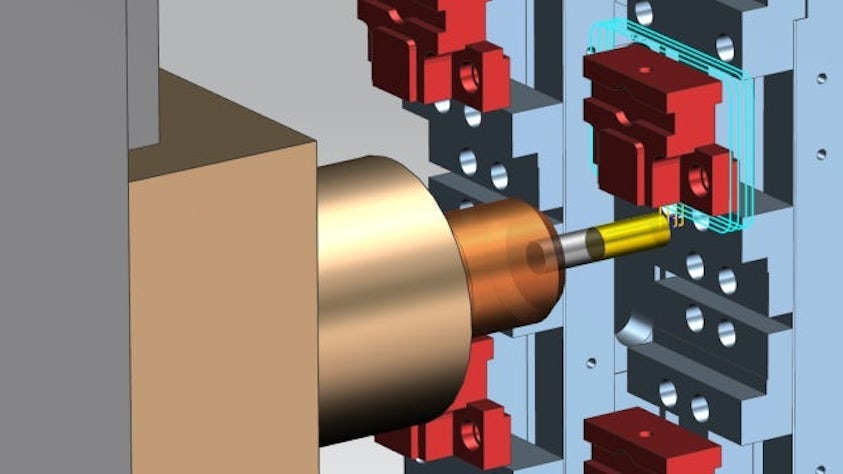

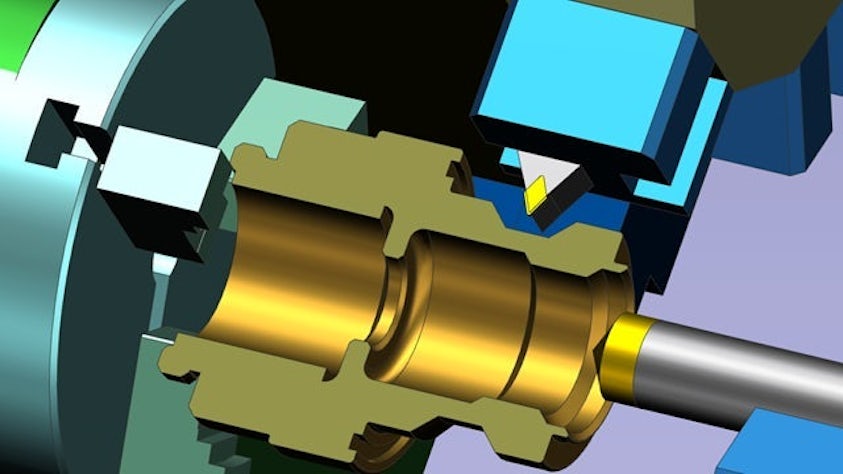

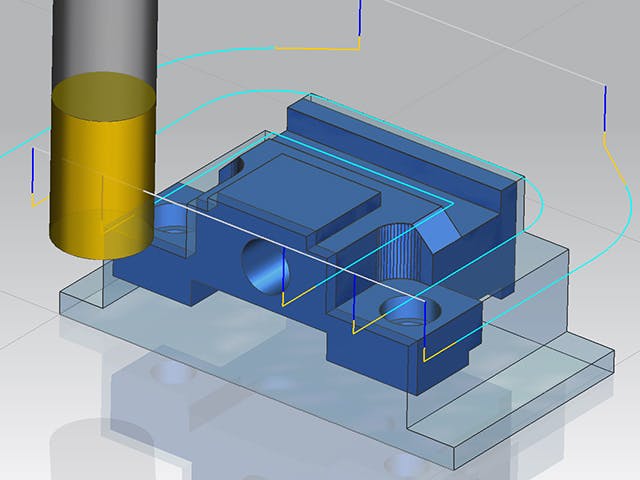

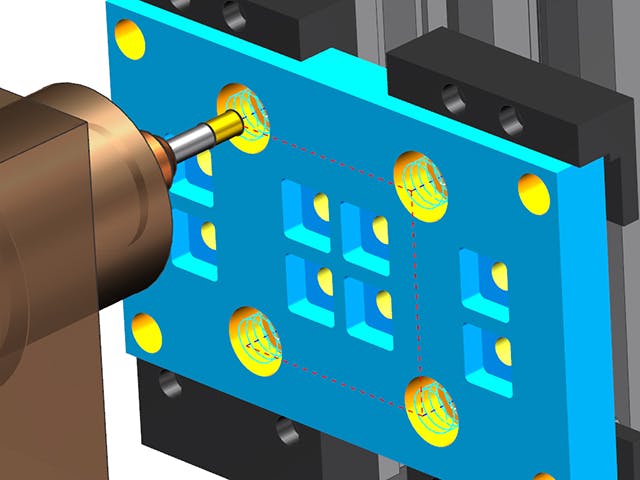

Verwenden Sie die Feature-basierte Bearbeitung, um automatisch Operationen zur Bearbeitung prismatischer Teile mit vielen Merkmalen wie Taschen, Löchern und Schlitzen zu erstellen.

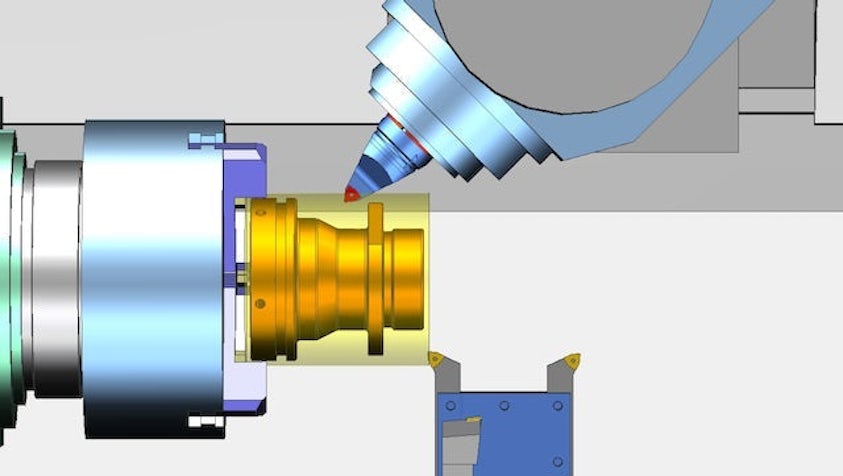

Erfassen Sie die Konstruktionsabsicht und automatisieren Sie den Prozess mithilfe der eingebetteten Produkt- und Fertigungsinformationen (PMI) weiter.

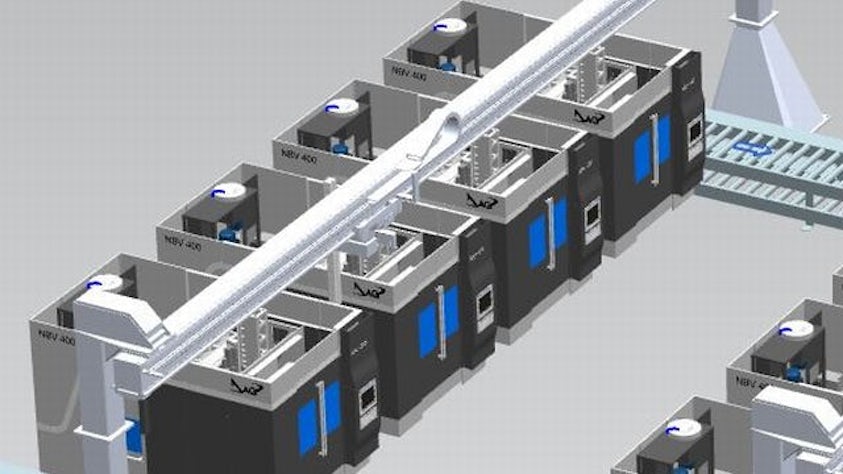

Prozessvorlagen und die Bearbeitungsdatenbank ermöglichen es Ihnen, Best Practices und bewährte Schnittdaten wiederzuverwenden und so eine Prozessstandardisierung zu ermöglichen.