Konstruktion, Optimierung und Berechnung von Fertigungsprozessen

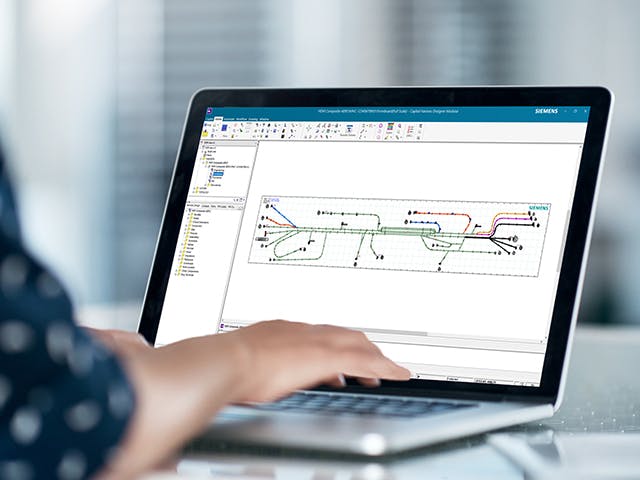

Kabelbaum-Formboard-Konstruktion

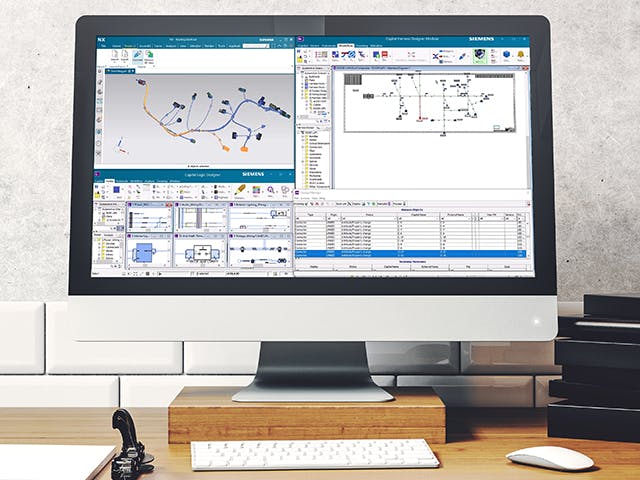

Mit Capital können Formboard-Konstrukteure ein optimiertes, ergonomisches Layout erstellen, das auf dynamischem Feedback des Arbeitsaufwands/der Arbeitszeiten für jede Komponente basiert.

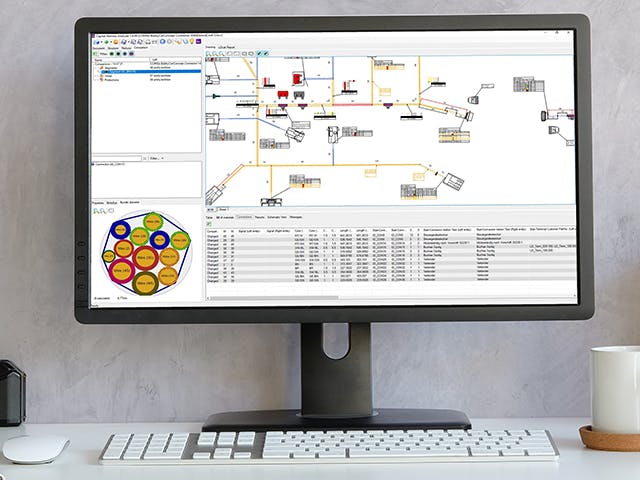

Teamcenter – Planung von Fertigungsprozessen

Verwenden Sie Capital, um Best-Practice-Techniken zu erfassen und auf die Planung des Kabelbaumherstellungsprozesses und die Kostenschätzung anzuwenden.

Kabelfertigung – Dokumentation

Die Qualität der Fertigungsdokumentation ist entscheidend, um Fehler bei den Builds zu minimieren. Erstellen Sie die Fertigungsdokumentation direkt aus den technischen Kabelbaumdaten und der definierten Montageprozess-Sequenz.

Nutzen des digitalen Zwillings zur Produktoptimierung

Nutzen Sie einen digitalen Zwilling mit Capital, um die Engineering-, Kosten- und Fertigungsleistung Ihres Unternehmens zu transformieren. Beseitigen Sie Dokumentationsfehler, senken Sie die Erstellungskosten und steigern Sie letztendlich den Gewinn.

Optimieren Sie Prozesse und verbessern Sie die Fertigungseffizienz

Vollständig detaillierte und verbesserte Kabelbaumkonstruktionen werden häufig in einer nicht maßstabsgetreuen 2D-Kabelbaumzeichnung dokumentiert. Fertigungsingenieure verwenden diese Informationen dann, um eine maßstabsgetreue Darstellung der Kabelbaumkonstruktionsdaten zu erstellen, die mit zusätzlichen Fertigungsinformationen angereichert ist und als Formboard-Zeichnung bezeichnet wird.

Zusätzlich zu den Kabelbaumkomponenten werden auf diesen Formboard-Zeichnungen alle fertigungsrelevanten Objekte wie Bündelgabeln, Steckerbefestigungen, Cliphalter und Bandpositionsanzeigen grafisch dargestellt und bieten den Bedienern visuelle Hilfen. Die leistungsstarke Grafik- und Design-Management-Umgebung für die Formboard-Konstruktion in Capital ermöglicht es Fertigungsingenieuren, schnell maßstabsgetreue, detaillierte und fertigungstaugliche Formboard-Diagramme zu erstellen.

Capital leitet Formboard-Konstrukteure an, ein optimiertes, ergonomisches Layout zu erstellen, das auf dem dynamischen Feedback des Arbeitsaufwands/der Arbeitszeiten für jede Komponente basiert, wenn sie in einer bestimmten Zone auf der Leiterplatte platziert wird. Konstrukteure können auch zusammengeführte oder kombinierte Formboards für effiziente Produktionslinien und die Nutzung von Fertigungsflächen erstellen und pflegen.

Erstellen einer Dokumentation zur Herstellung von Kabelbäumen

Angesichts der Komplexität heutiger Kabelbäume ist es von entscheidender Bedeutung, in der Lage zu sein, automatisch Bedieneranweisungen und visuelle Hilfsmittel für jede Konstruktions- und Produktionsanlage zu erstellen.

Die Qualität der Fertigungsdokumentation ist entscheidend, um Fehler bei den Builds zu minimieren. Erstellen Sie Dokumentationen direkt aus technischen Kabelbaumdaten und definierten Montageprozess-Sequenzen.

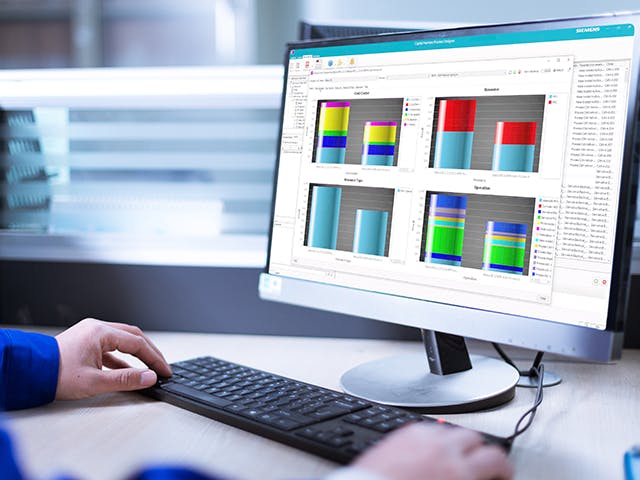

Effiziente Planung und Optimierung der Kabelbaumfertigung

Fertigungsprozessingenieure stehen oft vor der Herausforderung, ein effizientes Muster von aufeinanderfolgenden Prozessschritten zu bestimmen, die zu einer korrekten Montage des gewünschten Kabelbaums führen. Normalerweise gibt es mehr als ein mögliches Muster. Die optimale Wahl hängt von den spezifischen Fertigungsmöglichkeiten der betreffenden Produktionsstätte oder Produktionsstätten ab. Capital ermöglicht die automatische Erstellung eines effizienten Fertigungsschemas für jeden zu bauenden Kabelbaum. Dies wird erreicht, indem die Konstruktionen der Kabelbäume anhand der zuvor erfassten Beschreibungen der Fertigungsmöglichkeiten mit einer Logik zur Kabelbaummontage zerlegt werden.

Konstrukteure können Capital nutzen, um Best-Practice-Techniken zu erfassen und auf die Planung des Kabelbaumherstellungsprozesses und die Kostenschätzung anzuwenden. Es ermöglicht eine schnelle und genaue Prozessplanung und gibt Ingenieuren mehr Zeit, mehrere „Was-wäre-wenn“-Szenarien zu erstellen, die sich vergleichen und analysieren lassen, um eine optimale Fertigungseffizienz zu erzielen. Fertigungsingenieure können die von Capital angebotenen Funktionen nutzen, um effiziente Produktionslinien zu entwickeln, vorhandene Fertigungsressourcen so effektiv wie möglich zu nutzen und schnell auf neue Situationen wie geänderte Abnahmeraten zu reagieren. Es trägt dazu bei, bessere Entscheidungen in der Fertigung zu treffen und letztendlich die Zeit bis zur Rentabilität zu verkürzen.