Die Fertigungsstückliste dient als Masterdefinition, die das Unternehmen darüber informiert, was hergestellt werden soll, während die Stückliste (BOP) ergänzende Informationen zur Herstellung des Produkts enthält.

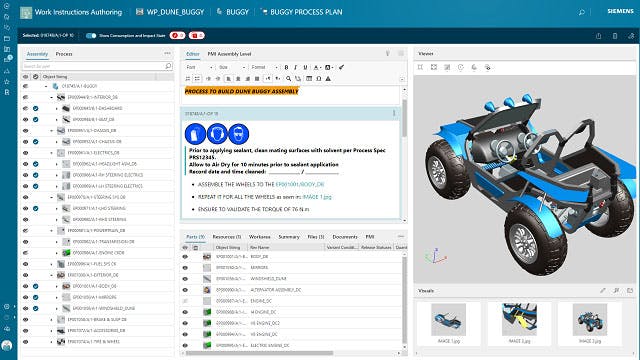

Die Fertigungsstückliste wird in einer Fertigungsprozessplanungssoftware innerhalb des Product Lifecycle Management (PLM)- Systems eines Herstellers generiert. Da Produkte in vielen Branchen komplexer geworden sind und mechanische, elektronische und Softwareentwicklung umfassen, ist die Erstellung der MBOM innerhalb einer integrierten PLM-Software unerlässlich geworden, um Genauigkeit und Flexibilität zu gewährleisten.

Die Fertigungsstückliste unterscheidet sich von der Konstruktionsstückliste (Engineering Bill of Materials, EBOM). Ein modernes PLM stellt jedoch sicher, dass alle Stücklisten, die mit einem Produkt verbunden sind, definiert und konsistent verwaltet werden. Während die EBOM betont, wie sich Materialien und Teile auf das funktionale Design des Produkts beziehen, spiegelt die MBOM wider, wie die Materialien und Teile ein vollständiges Produkt bilden. Die Stückliste basiert auf Konstruktionsdaten und die Stückliste auf der Stückliste.

Verwandte Produkte: Teamcenter | Planung des Fertigungsprozesses