EWIS steht für Electrical Wiring Interconnect System. Es ist reguliert, um die Sicherheit komplexer Systeme, wie z. B. Flugzeuge, zu gewährleisten.

Warum ist EWIS notwendig?

Die Leistung und Sicherheit eines Flugzeugs hängen von der Integrität des elektrischen Systems während der gesamten Lebensdauer des Flugzeugs ab. Das EWIS ist ein kritisches Flugzeugsystem, das für einen sicheren Betrieb erforderlich ist, was die Aufrechterhaltung einer genauen und zuverlässigen Funktion und Kommunikation im gesamten elektrischen System erforderlich macht.

Die EWIS-Vorschriften verlangen, dass elektrische Komponenten auf der Grundlage ihrer elektrischen Spezifikationen ausgewählt und unter extremen Bedingungen, denen die Komponente ausgesetzt sein kann, geprüft und getestet werden. Die EWIS-Vorschriften legen auch Richtlinien für die korrekte Installation und den Schutz von Komponenten sowie eine ausreichende Designdefinition fest, um die Wiederholbarkeit in den Herstellungs- und Wartungsprozessen zu gewährleisten. Die EWIS-Vorschriften legen einen höheren Standard für die Zuverlässigkeit und Sicherheit des Systems fest als frühere Vorschriften.

EWIS-Softwarelösungen

Moderne Flugzeuge verfügen über mehr elektrische Inhalte, um eine höhere Leistung und Leistungsfähigkeit zu bieten. Infolgedessen benötigen elektrische Systeme mehr Leistung und stellen aufgrund der erhöhten Komplexität ein höheres Compliance-Risiko dar. Um diesen vielen Herausforderungen zu begegnen, umfassen hochwertige E/E-Softwarelösungen Analyse- und Simulationswerkzeuge, die Benutzer dabei unterstützen, die Einhaltung gesetzlicher Vorschriften zu einem früheren Zeitpunkt im Designprozess für Aufgaben wie die Durchführung von elektrischen Lastanalysen (ELA) zu validieren.

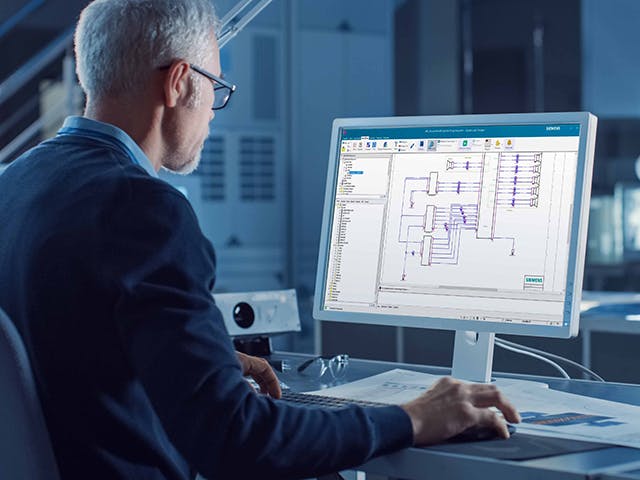

Das Ziel moderner Softwarelösungen und Technologien ist es, das elektrische Design, die Konformität und die Zertifizierung von Flugzeugen zu optimieren. Zum Beispiel ist Capital Load Analyzer, Teil der Capital ® Software-Suite von Siemens Digital Industries Software, eine der ersten elektrischen Systemtechnologien der Branche, die den digitalen Zwilling, die Designautomatisierung und die digitale Datenkontinuität nutzt, um die Einhaltung gesetzlicher Vorschriften zu erleichtern.

Dieser Ansatz zum Ausfüllen einer ELA folgt anerkannten Richtlinien und bietet ein zweckmäßiges Mittel, um die folgenden wichtigen Compliance-Perspektiven zu berücksichtigen:

- Verwalten Sie die für ELA erforderlichen Informationen, wie z. B. einpolige Schaltpläne, Betriebsszenarien (alle Flugphasen), Analysenotizen usw.

- Durchführen von ELA-Iterationen, ELA-Berichten und ELA-Analysen und Berichtsiterationen

- Zeigen Sie die Konformität für jede Konfiguration nach Bedarf an

EWIS und seine Herausforderungen

Eine Implikation des zunehmenden Einsatzes elektrischer Lösungen zur Erfüllung anspruchsvollerer Leistungs- und Missionsanforderungen ist die zunehmende Größe, das Gewicht und die Komplexität des EWIS. Mit der zunehmenden Nutzung digitaler Kommunikation haben sich EWIS-Inhalte von einfachen, analogen Punkt-zu-Punkt-Verbindungen zu ausgefeilteren digitalen Netzwerkbussen verlagert. Dies wiederum kann teure Datenkabel erfordern, die die EWIS-Kosten und die Fertigungskomplexität in die Höhe treiben. Die Komplexität von EWIS wird durch eine Vielzahl von Regeln zur Minimierung elektrischer Interferenzen, zur Signaltrennung für redundante Systeme und natürlich zur Sicherstellung der Konformität und/oder kommerziellen Zertifizierung weiter verschärft.