Enabling students to produce a comprehensive digital twin of a turbojet engine

The University of Bordeaux uses Simcenter Amesim to enhance students’ understanding of multiphysics simulation

University of Bordeaux

The University of Bordeaux is a public university based in Nouvelle-Aquitaine in southwestern France. It has campuses in the cities and towns of Bordeaux, Dax, Gradignan, Périgueux, Pessac and Talence. There are also several smaller teaching sites in other towns in the region, including in Bayonne.

https://www.u-bordeaux.com/- Headquarters:

- Bordeaux, France

- Products:

- Simcenter Products, Simcenter Amesim

- Industry Sector:

- Aerospace & defense

Our partnership with Siemens is vital. By using the latest technology, we can prepare our students to be ready to hit the ground running in their first job after graduating.

University of Bordeaux

Specialists in aeronautical maintenance

The Evering Institute at the University of Bordeaux is the only school in France that teaches aeronautical maintenance at a master level. It involves a mixture of academic research and industrial partnership projects. Students receive half of their training from academic teaching and the other half from industry professionals with work experience and internships.

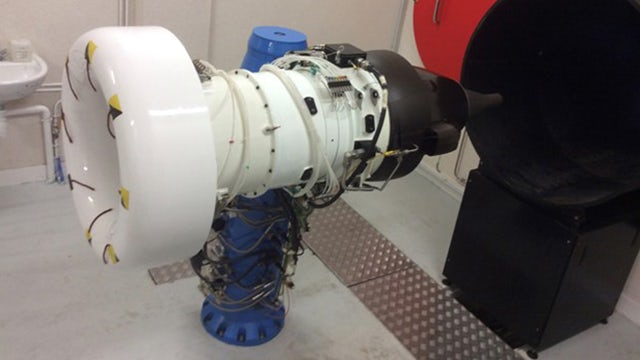

The institute has extensive equipment to support student learning, including a turbojet engine test bench. However, when the engine broke down after several years of use, it required a lengthy repair that impacted student learning. Siemens Digital Industries Software suggested creating a comprehensive digital twin of the engine during its repair using Simcenter™ Amesim™ software. This enabled the institute to continue teaching students while the engine was out of service. It also introduced them to simulation tools that would benefit them in the future.

Simcenter Amesim is part of the Siemens Xcelerator business platform of software, hardware and services. Simcenter Amesim was an excellent tool for this project because it was designed to virtually assess the performance of systems such as turbojet engines.

Benefiting education and industry

Pierre Francois, engineering professor at the Evering Institute, explains that multiphysics simulation is rarely taught at universities, so this was a great opportunity to show students how it can be applied: “For example, on an aircraft engine, which is not pedagogical equipment, we cannot create and realize states of failure or malfunction of an engine. This can only be done by simulation, hence the importance of teaching it to students so they can simulate or develop future predictive maintenance algorithms.” Using simulation enabled students to understand how to use a tool to carry out predictive maintenance on a turbojet engine. This helped them learn how to use tools and artificial intelligence (AI) to diagnose breakdowns and plan predictive maintenance.

Learning on the job

To get the most out of the project, Benjamin Florence, a student at the Evering Institute, undertook an internship with Siemens Digital Industries Software where he developed his simulation skills.

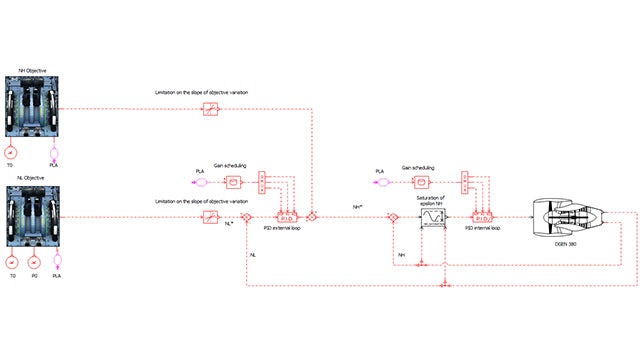

First, Florence learned how to develop and validate the turbojet engine digital model. He was also trained in coupling with control systems – model-in-the-loop (MiL), software-in-the-loop (SiL) and hardware-in-the-loop (HiL) – and applying simulation to deal with engineering problems in the industry. He then acted as project leader for the second phase of the project, working with his fellow students at the institute to complete the comprehensive digital twin.

“Simcenter Amesim is very intuitive with an extensive help section,” states Florence. “There are demonstration models that display how simulations work and prebuilt libraries of component models so we didn’t have to create everything from scratch. There’s also a great schematic logic that enables you to build your entire engine from the different component models.”

Simulation and testing working together

After completing the digital twin, Florence compared simulation results with previously recorded engine test data. The results differed by under 5 percent, which was well within the modeling boundaries of the project.

Florence and the other students on the project created a template for future students to use. “We’ve produced a document that walks students through the process of creating a simulation using Simcenter Amesim,” states Florence. “We’ve also made a correction file for teachers so they can quickly compare the results that students are getting and help them if needed.”

The comprehensive digital twin is not intended to replace the physical engine completely, but to be used alongside the engine. “It’s critical for the simulation result to be reliable and trustworthy in aeronautical maintenance,” explains Francois. “By combining our physical equipment with the simulation model, we can show students the sources of uncertainty, orders of magnitude and the cases where there can be incorrect interpretations.”

Using Simcenter Amesim enabled the students to carry out tests they could not previously perform. “The multiphysics model makes it possible to carry out experiments that can’t be done with the engine,” says Francois. “For instance, creating a drop in performance or efficiency is difficult if not impossible. With the digital twin, it’s much more feasible.”

Preparing students for the future

“This experience has opened my eyes to the full possibilities of simulation,” states Florence. “The Siemens internship has been a great help and will be invaluable in my career after university.”

In the future, when the physical engine is available, students will be able to run simulations in parallel with physical tests and compare the results. They can carry out experiments with the comprehensive digital twin, trying out different theories and ideas without damaging the engine. When they are confident, they can carry out the same experiments on the physical engine. This also helps with the development of predictive maintenance algorithms for the industry. “We can’t force breakdowns or malfunctions of noneducational equipment,” says Francois. “However, we can simulate it with accurate models.”

Using simulation allows more teaching to be done in the same amount of time since teachers don’t have to wait for the physical engine to be available. “It enables us to pass on concepts and enhance our students’ skills,” Francois says. “It’s important for students to understand this software so they’re ready to use it in their professional life.”

What’s next for universities and industry

Francois expects scientific technical education to be more oriented toward professional skills in the future. “Students will find themselves working more on projects in teams, solving real-world cases using a combination of simulation and physical testing,” states Francois.

This will enhance their learning and set them up for a successful career beyond university. “Multiphysics simulations will make it easier for students to acquire the knowledge they need at university and there will be time to collaborate with the industry and work on real issues.”

Digitalization is the key to the future because it enables better and faster collaboration and broader learning. “Digital technology makes it easier to share information and knowledge between engineering schools and with commercial companies,” explains Francois. “As an exercise, we could have students creating micro companies in association with different engineering schools to help them acquire commercial or managerial skills alongside technical or scientific skills.”

The next revolution

The biggest change the institute foresees is how modern simulation tools will be used to develop predictive engineering and AI techniques. “This could have an equal impact as the move from pencil and paper to CAD had in the 1970s and 1980s,” states Francois. “It will revolutionize the design office again so students must be ready for that. It won’t replace the intelligence of the engineer, but it will help them process more data faster. The tools will only be as good as their user so engineers must understand how to use them correctly.”

Keeping up with the latest developments in aeronautical engineering introduces new challenges for schools like the Evering Institute. Francois concludes, “Our partnership with Siemens is vital. By using the latest technology, we can prepare our students to be ready to hit the ground running in their first job after graduating.”

Multiphysics simulations will make it easier for students to acquire the knowledge they need at university and there will be time to collaborate with the industry and work on real issues.

University of Bordeaux