Computer-aided design (CAD) is the use of computer programs to create, modify, analyze and document two- or three-dimensional (2D or 3D) graphical representations of physical objects as an alternative to manual drafts and product prototypes. CAD is widely used in computer animation and media special effects as well as in product and industrial design.

What is NX CAD?

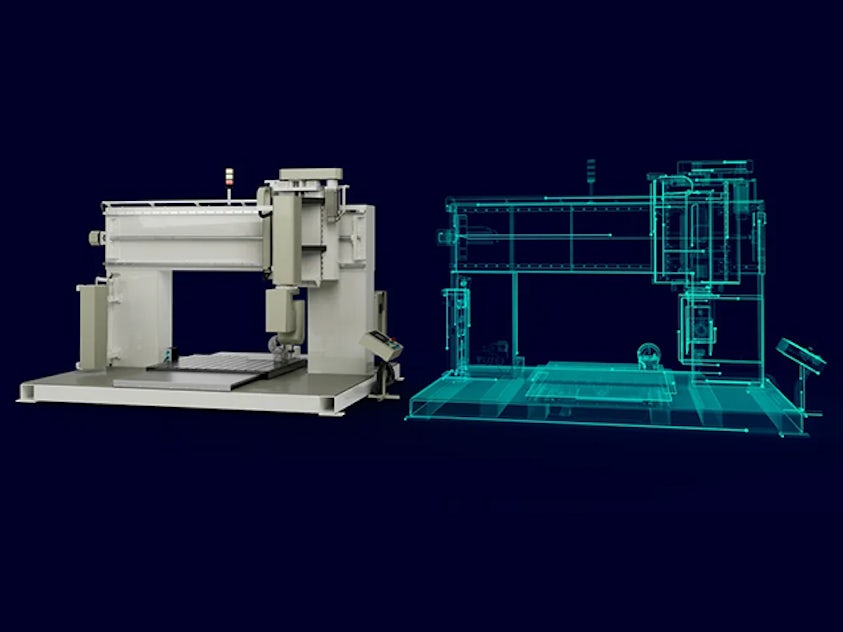

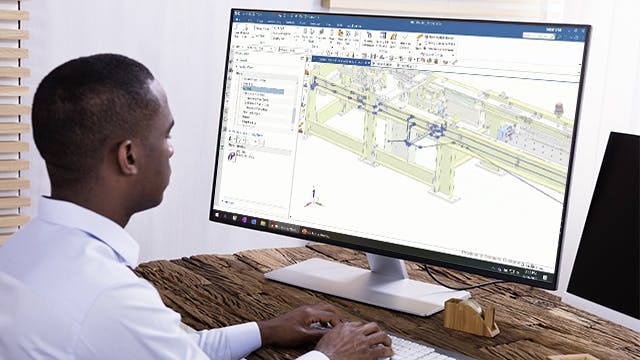

NX CAD is a mechanical product design solution developed by Siemens that helps companies boost product design efficiency and quality. It enables the most comprehensive digital twin of the product by seamlessly connecting teams, processes, systems and data involved in the product design.

It is the first major mechanical computer-aided design (MCAD) system to be certified as an open system that provides easy integration and has a proven track record of helping customers advance their data without disruption. It is the only CAD solution to support token licensing, a highly flexible approach to delivering add-on solutions. It is now available on the cloud, as-a-service (NX X), to help you accelerate your digital transformation easier, faster and at scale.

What is Solid Edge CAD?

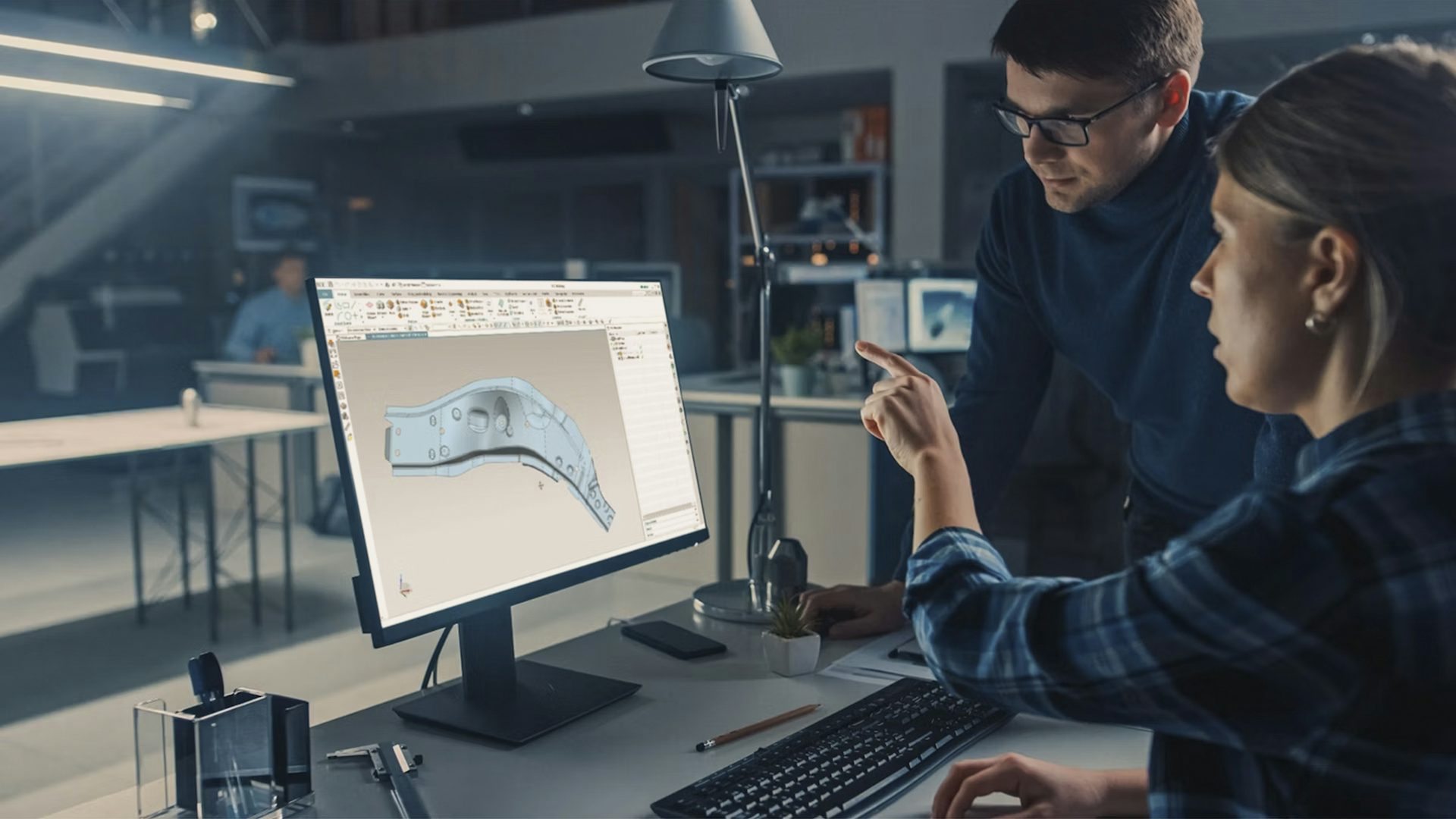

Solid Edge CAD is a Siemens technology that engineers, product developers and designers use to create functional, virtual prototypes of three-dimensional objects. With Solid Edge, designers can dynamically create and modify every detail of a product, part or assembly. 3D CAD software facilitates and automates other aspects of product engineering, such as simulation testing, drawing and drafting, manufacturing, data management, computer-generated animation, and more. These three-dimensional models can be used in simulation studies to predict how the object will respond to stress and environmental factors, they can be rendered to create photo-realistic images for use in sales and marketing materials and/or detailed drawings can be sent to manufacturing for production (or, in the case of additive manufacturing, the CAD file can be sent directly to a 3D printer).

Modeling in CAD

Traditionally, there are two main approaches to creating and modifying geometry in 3D CAD: history-based (also known as ordered or feature-based) modeling or direct modeling. In history-based modeling, the structure and order of features control how models react to changes or edits. This creates predictable results from edits on underlying feature sketches using precise dimension changes. Direct modeling doesn't maintain a history of features or record how a model is built. There are no sketches driving features that make up the part. Editing is done by simply selecting what you want to change and changing it.

Related products: NX CAD

.jpg?auto=format,compress&w=640&q=60)

.jpg?auto=format,compress&w=640&q=60)