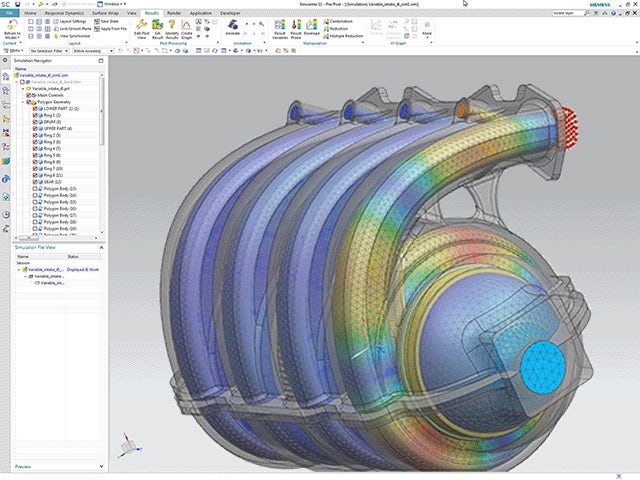

Das Verständnis und die Bereitstellung domänenübergreifender Leistung erfordert Simulations- und Testlösungen, die in allen Entwicklungsphasen und in allen Leistungsbereichen und in der Physik eingesetzt werden können. Darüber hinaus müssen diese Aktivitäten miteinander verknüpft und nicht unabhängig voneinander durchgeführt werden, um reale multiphysikalische Phänomene zu erfassen und widersprüchliche Attribute auszugleichen. Simcenter bietet ein integriertes Portfolio erstklassiger prädiktiver Simulations-, Test- und Design-Explorationslösungen, die alle Phasen des Produktentwicklungsprozesses abdecken, um die schwierigsten Probleme im Engineering zu lösen und die Technik zu transformieren, indem sie die Produktivität steigern und Innovationen fördern.

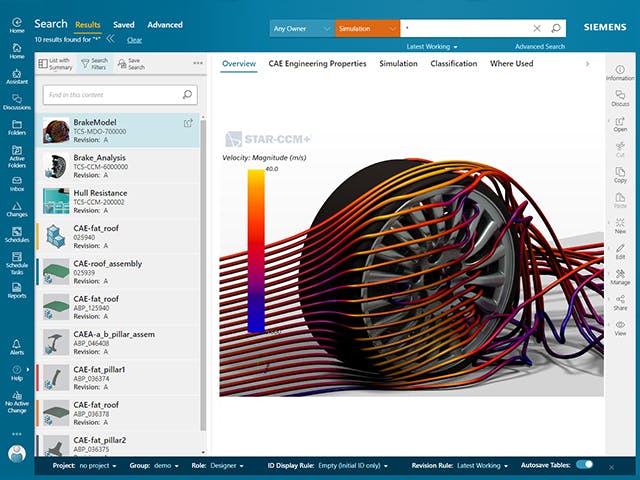

Simulation und Test können nicht mehr als isolierte Aktivitäten betrachtet werden. Der digitale Zwilling liefert einen Mehrwert über den gesamten Lebenszyklus hinweg, und seine Entwicklung muss im Hinblick auf die Rückverfolgbarkeit und die Auswirkungen von Änderungen gesteuert werden. Dies ist nur möglich, wenn Simulationen und Tests als Teil einer umfassenden digitalen Produktentwicklungsinitiative bereitgestellt werden. Siemens Xcelerator verwischt die Grenzen zwischen Engineering-Domänen wie Elektrik, Mechanik und Software, und Simcenter Simulations- und Testlösungen ergänzen die Siemens Xcelerator-Lösungen in den Design-, Realisierungs- und Optimierungsphasen des Lebenszyklus.

Auf dem Weg zur digitalen Transformation brauchen Unternehmen verlässliche Partner mit den Ressourcen, um Innovationen in den Tools und Anwendungen kontinuierlich voranzutreiben. Siemens investiert erheblich in Forschung und Entwicklung, nutzt Partnerschaften mit etablierten Unternehmen in angrenzenden Bereichen und investiert in Start-ups, die über die Technologien verfügen, die das Geschäft in Zukunft verändern könnten. All dies sorgt für einen stetigen Strom von Innovationen, die unseren Kunden helfen können, auf dem neuesten Stand zu bleiben und die Vorteile der Digitalisierung schneller als ihre Wettbewerber zu nutzen. Die Engineering- und Consulting-Services von Simcenter bieten fundiertes Fachwissen, Einrichtungen, Ressourcen und Know-how, um die Transformation von Engineering-Prozessen und die daraus resultierende Kapitalrendite zu beschleunigen.