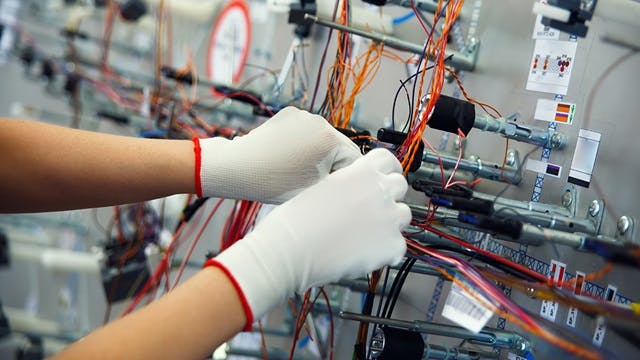

Software für die Elektrokonstruktion sind spezialisierte Werkzeuge, die Ingenieure und Konstrukteure verwenden, um die Herausforderungen der komplexesten Produkte von heute zu meistern. Zu diesen Herausforderungen gehören Konnektivität, Sicherheit und Kostenkontrolle. Es stellt sicher, dass die Signale von elektronischen Einheiten, z. B. mit eingebetteter Software , oder elektromechanischen Geräten, wie z. B. einem Schalter oder einem Motor, korrekt angeschlossen werden. Es wird verwendet, um eine sichere und robuste Stromversorgung aller Komponenten in einem System zu bestätigen und auch das elektrische Verteilungssystem hinsichtlich Gewicht, Kosten und mechanischer Verpackung zu optimieren. Mit dieser spezialisierten Software können Sie sicherstellen, dass das Design den Vorschriften entspricht.

Diese Herausforderungen wachsen, getrieben durch die Tatsache, dass innovative Produktfunktionalität heute hauptsächlich von elektrischen, elektronischen und Softwaresystemen bereitgestellt wird. Software, die speziell für die E /E-Entwicklung entwickelt wurde, hilft Ihnen, in einer Zeit steigender Komplexität zu entwerfen, herzustellen, zu dokumentieren und zu warten.