Was ist intelligente Fertigung in der Luft- und Raumfahrt?

Die intelligente Fertigung in der Luft- und Raumfahrt umfasst die Aktualisierung von Produktionsprozessen, um die Effizienz zu steigern und Risiken zu reduzieren. Es beginnt mit der Verbindung des Engineerings mit der Fertigung mit einem modellbasierten Fertigungsplan. Nutzen Sie einen digitalen Zwilling, um diesen Plan vor der physischen Inbetriebnahme virtuell zu validieren. Implementieren Sie schließlich fortschrittliche Fertigungstechnologien, um Produkte und Prozesse kontinuierlich zu optimieren.

Bauen Sie schon heute Ihre Luft- und Raumfahrtfabrik der Zukunft

Die digitale Transformation Ihrer Fertigungsprozesse in der Luft- und Raumfahrt kann Ihnen helfen, Ihre Fabrikhalle zu optimieren und den Produktionsstart zu beschleunigen. Hersteller in der Luft- und Raumfahrt, die einen intelligenten Fertigungsprozess einführen, können entscheidende Vorteile erzielen:

Verkürzung der Inbetriebnahmezeit

Beschleunigen Sie die digitale Transformation, um die Produktionsleistung und -flexibilität zu steigern und gleichzeitig die Qualität zu optimieren. (In der Luft)

Verbesserung des Durchsatzes

Erreichen Sie die Produktionsziele in der Luft- und Raumfahrt und steigern Sie den Wettbewerbsvorteil in Ihrem gesamten Fertigungsprozess. (Deloitte)

Verkürzung der Arbeitszeit

Reduzieren Sie die Zeit für die detaillierte Strukturplanung durch den Einsatz unserer intelligenten Fertigungslösungen. (General Atomics Aeronautical Systems, Inc.)

Digitale Transformation Ihres Produktionsprozesses in der Luft- und Raumfahrt

Verbinden Sie technische Disziplinen und Prozesse, planen, optimieren und testen Sie Ihre Fabrikhalle virtuell und beschleunigen Sie den Produktionshochlauf, um die Ziele für den Produktionsdurchsatz schneller zu erreichen. Erfahren Sie mehr über die wichtigsten Säulen der intelligenten Fertigung für Luft- und Raumfahrt:

Modernisieren Sie Ihre Fertigungsprozesse in der Luft- und Raumfahrt, indem Sie Daten aus allen technischen Disziplinen mit der Fertigung verbinden, um einen modellbasierten Fertigungsplan zu erstellen. Dieser "Shift Left"-Ansatz trägt dazu bei, eine Produktion mit Produkten zu gewährleisten, die den Designspezifikationen entsprechen.

Aktualisieren Sie Ihre Legacy-Geräte mit intelligenten Technologien, um einen umfassenden digitalen Zwilling zu erstellen. Simulieren Sie Fertigungsszenarien, um den Betrieb zu optimieren. Auf diese Weise können Sie Ihren Fertigungsplan vor der physischen Inbetriebnahme virtuell validieren und schneller eine intelligente Fabrikhalle erreichen.

Schaffen Sie eine flexible, vernetzte Luft- und Raumfahrtfabrik der Zukunft, indem Sie die Leistung überwachen und Betriebsprobleme mithilfe von Sensoren und intelligenten Geräten in Echtzeit vorhersagen. Die Etablierung dieses Closed-Loop-Prozesses erhöht die Flexibilität und Transparenz Ihrer Fertigungsumgebung.

Optimieren Sie Ihre Produktionsstrategie für die Luft- und Raumfahrt

Pünktliche Lieferrate

Der Kunde erzielte eine pünktliche Lieferrate von bis zu 96 % bei der Verwaltung verschiedener Materialien und Teiletypen. (Proform)

Steigerung des Outputs

Nutzen Sie Automatisierung und Digitalisierung, um Engpässe aufzudecken und die Produktion zu optimieren. (In der Luft)

Erhöhte Produktionskapazität

Verkürzen Sie die Produktionsvorlaufzeit und erhöhen Sie die Kapazität und Auslastung. (GKN Luft- und Raumfahrt)

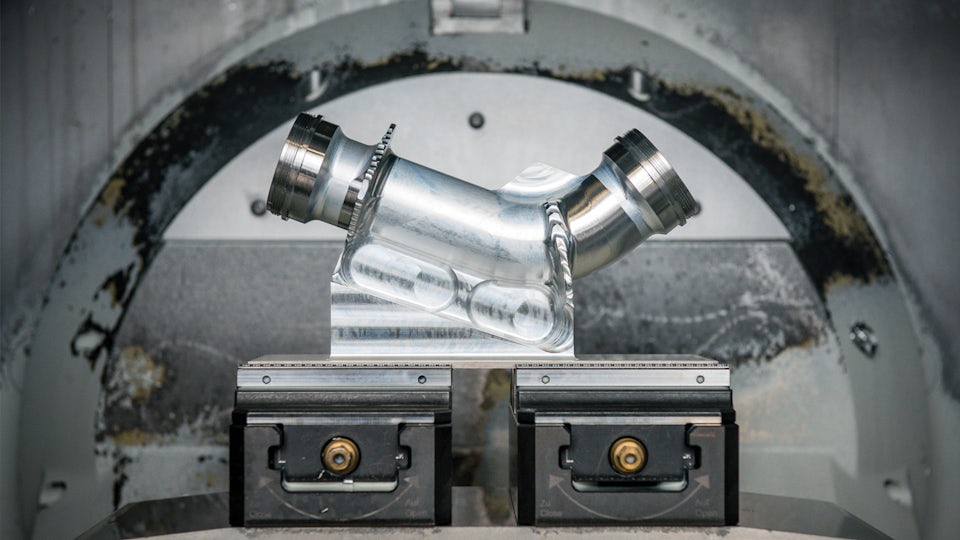

High-precision manufacturer pursues digitalization with Siemens Digital Industries Software solutions

Firma:Armor Meca

Branche:Luft- und Raumfahrt

Standort:Pleslin-Trigavou, France

Siemens Software:NX, Opcenter APS, Teamcenter

"Mit den Softwarelösungen von Siemens automatisieren wir unsere Produktionsmethoden effektiv, indem wir digitale Zwillinge unserer Werkzeugmaschinen implementieren und unsere Produktionsabläufe optimieren."

Erkunden Sie unsere Ressourcenbibliothek

Erfahren Sie mehr über den Umgang mit Veränderungen in der A&D-Branche und wie Sie die digitale Transformation in der Fertigung nutzen können. Entdecken Sie Blogs, E-Books und mehr, um diese Konzepte zu nutzen und die digitale Transformation in Ihrem Fertigungsprozess für langfristigen Erfolg zu erreichen.

Intelligente Lösungen für den Erfolg in der Luft- und Raumfahrtfertigung

Planung von Fertigungsprozessen

Herstellung von Kabelbäumen

Werkzeug- und Teilebau

Manufacturing Execution Management

Qualitätsmanagement

Additive Entwicklung und Fertigung

Häufig gestellte Fragen

Wie kann ich die Chancen erhöhen, dass meine Luft- und Raumfahrtprodukte durchgängig ihrem zugelassenen Design entsprechen?

Um die Produktion Ihrer Luft- und Raumfahrtprodukte auf Anhieb zu gewährleisten, müssen Sie einen intelligenten Fertigungsansatz implementieren. Dieser Ansatz für die Luft- und Raumfahrtproduktion umfasst:

- Erstellung eines modellbasierten Fertigungsplans, der Ihre Konstruktionsdaten mit der Fertigung verbindet

- Nutzung eines digitalen Zwillings Ihrer Luft- und Raumfahrtfabrik, mit dem Sie Ihre Fabrikhalle virtuell testen und Ihren Produktionsplan validieren können

- Implementierung fortschrittlicher Fertigungstechnologien und Erkenntnisse aus dem geschlossenen Kreislauf, um Probleme vorherzusagen und zu beheben und Produkte und Prozesse kontinuierlich zu verbessern

Wie beschleunigt Software für die Luft- und Raumfahrttechnik die Produktion?

Unsere Lösungen können Ihnen helfen, die Produktion zu beschleunigen, indem Sie Vorrichtungen, Vorrichtungen, Lehren und andere Werkzeugausrüstungen für Fertigungsvorgänge nach genauen Spezifikationen entwerfen.

Warum ist die additive Fertigung in der Luft- und Raumfahrt wichtig?

Hersteller in der Luft- und Raumfahrt stehen unter erhöhtem Druck, Produkte schneller zu liefern und gleichzeitig dem Design zu entsprechen. Die additive Fertigung in der Luft- und Raumfahrt kann dazu beitragen, die Effizienz zu verbessern, indem sie Prototypen von 3D-gedruckten Werkzeugen, Vorrichtungen, Vorrichtungen und Fertigprodukten erstellt. Dieser Ansatz bringt das Rohmaterial in die Nähe des fertigen Teils, wodurch Rohstoffkosten und Abfall minimiert werden. Durch die bedarfsgerechte Herstellung von Teilen am Servicestandort reduziert die additive Fertigung die Lager- und Versandkosten. Die additive Fertigung, unterstützt durch unsere Siemens Xcelerator-Lösungen , ermöglicht es Unternehmen, Produkte neu zu denken, die Fertigung umzurüsten und Geschäftsmodelle zu überdenken.

Wie sieht die Zukunft von Verbundwerkstoffen in der Luft- und Raumfahrt aus?

Verbundwerkstoffe für die Luft- und Raumfahrt werden immer wichtiger, da sie den Herstellern helfen, wichtige Anforderungen wie Gewichtsreduzierung, Erhöhung der Nutzlast und Reduzierung des Kraftstoffverbrauchs zu erfüllen. Um diese Vorteile nutzen zu können, müssen Hersteller in der Luft- und Raumfahrt in der Lage sein, Verbundwerkstoffkomponenten mit hoher Präzision und Produktionsausbeute sowie Betriebsfestigkeit und Reparierbarkeit zu entwerfen und herzustellen. Die Lösungen innerhalb des Siemens Xcelerator-Portfolios können die Konstruktion und Fertigung von Verbundwerkstoffen unterstützen.

Welche Vorteile bietet die Automatisierung der Luft- und Raumfahrt?

Die Automatisierung in der Luft- und Raumfahrtfertigung trägt zur Verbesserung von Effizienz, Sicherheit und Durchsatz bei. Robotik und künstliche Intelligenz beschleunigen den Betrieb, während Sensoren und intelligente Geräte die Leistung überwachen und Betriebsprobleme in Echtzeit vorhersagen.

Wie unterstützt Siemens-Software die Fertigung in der Luft- und Raumfahrt, einschließlich der Fertigung von Teilen für die Luft- und Raumfahrt?

Unsere Smart-Manufacturing-Lösungen ermöglichen es Unternehmen, die digitale Transformation des gesamten Produktionsprozesses zu beschleunigen. Mit unserem Siemens Xcelerator-Portfolio an Softwarelösungen können Sie Engineering-Disziplinen und -Prozesse miteinander verbinden. Planen, optimieren und testen Sie Ihre Fabrikhalle virtuell; und beschleunigen Sie den Produktionshochlauf, um die Ziele für den Produktionsdurchsatz schneller zu erreichen. Dies gewährleistet Transparenz über den gesamten Produktlebenszyklus und ermöglicht es Ihnen, konsistente Produkte zu liefern, die dem genehmigten Design entsprechen.

Weitere Informationen

Zum Video

On-Demand-Webinar | Digitale Transformation in der Luft- und Raumfahrtfertigung

Zum Video | Intelligente Fertigung in der Luft- und Raumfahrt

Lesen

E-Book | Intelligente Fertigungslösungen in der Luft- und Raumfahrt

E-Book | Vier Schlüssel zur Optimierung von A&D-Produktionsprozessen

E-Book | Digitale Lösungen für die Modernisierung der A&D-Fertigungsabläufe

Mehr Informationen

Ressourcen-Bibliothek | Kabelbaumfertigung in der Luft- und Raumfahrt

Ressourcen-Bibliothek | Modernisierung von Fertigungsprozessen in der Luft- und Raumfahrt

Ressourcen-Bibliothek | Management von Fertigungsabläufen in der Luft- und Raumfahrt

Sind Sie bereit für eine Verbindung?

Wenden Sie sich mit Fragen oder Kommentaren an uns. Wir sind hier, um zu helfen!