Wie können Sie hochpräzise, qualitativ hochwertige, kundenspezifische und nachhaltige Komponenten pünktlich und in großem Maßstab herstellen – und das alles bei gleichzeitiger Verbesserung Ihrer Gesamtproduktivität und Rentabilität?

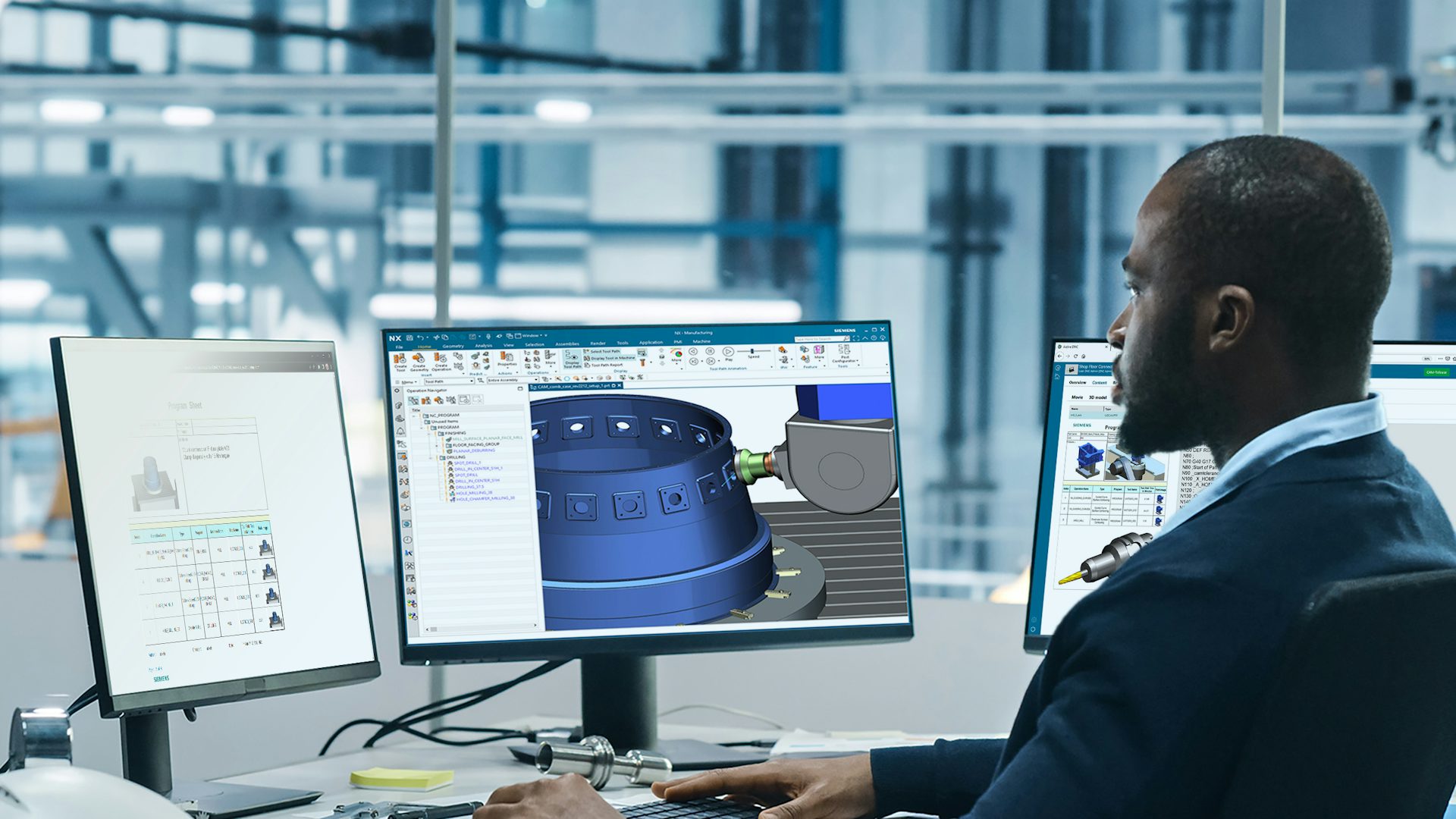

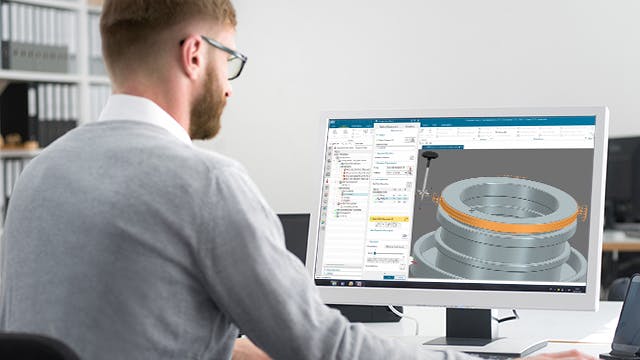

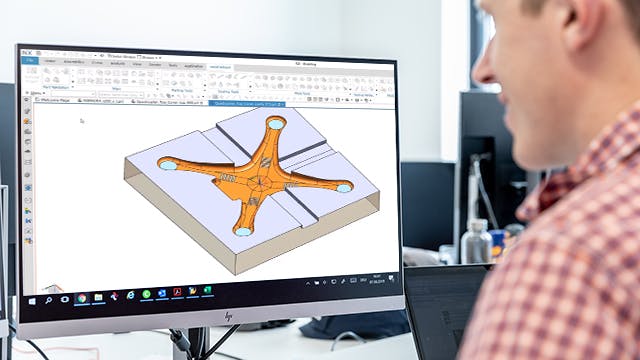

Implementieren Sie eine integrierte Softwarelösung für die Werkzeug- und Teilefertigung. Automatisieren und verbinden Sie Konstruktion, Produktion und Betrieb in der digitalen Maschinenwerkstatt nahtlos mit einer bewährten, leistungsstarken Suite von Software-Tools und -Lösungen.