Prezentuje: Daimler

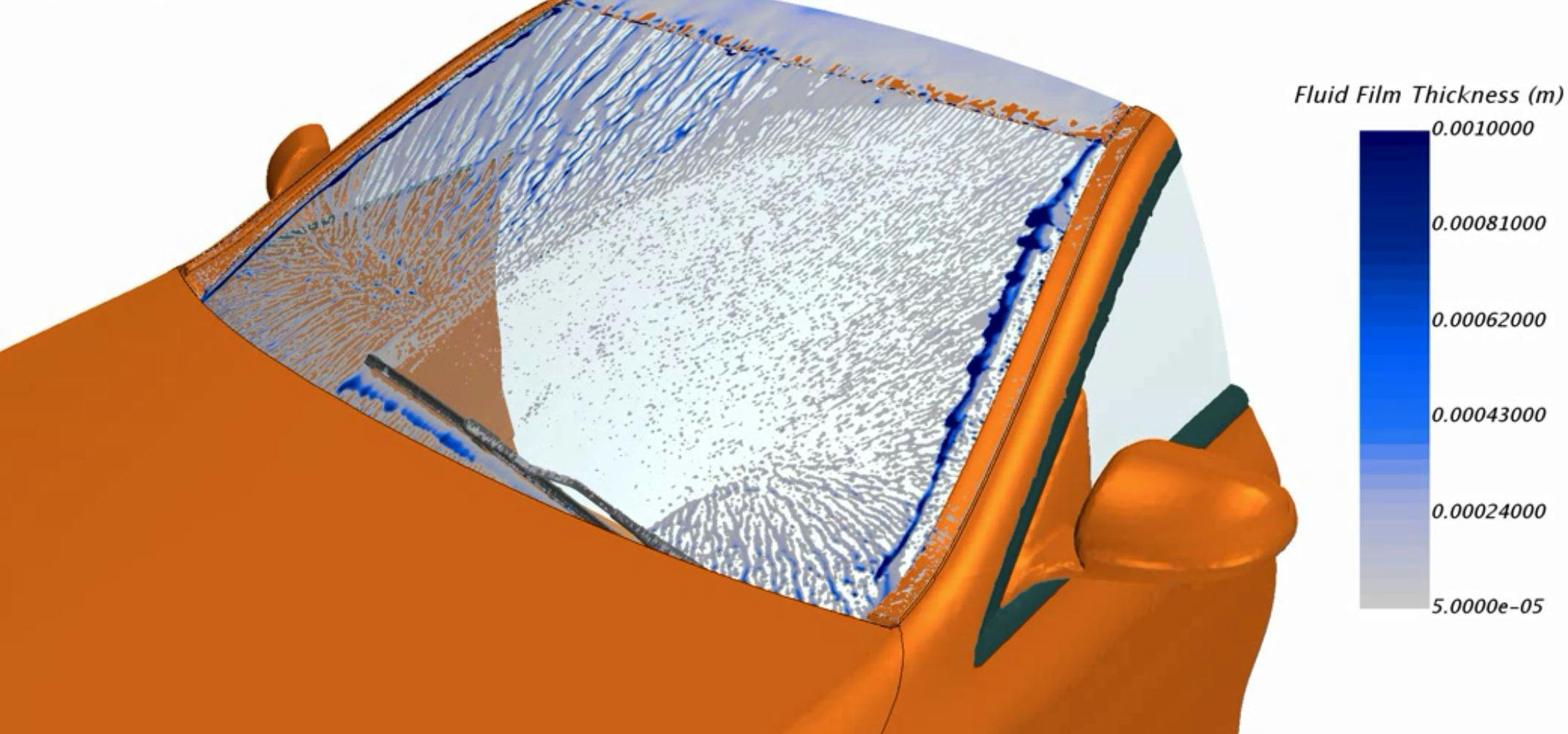

Znalost a pochopení interakce vozidla s vodou jsou klíčové při zajišťování kritických atributů, zejména bezpečnosti, spolehlivosti a kvality. V této souvislosti se konstruktéři zajímají především o to, jak návrh vnější aerodynamiky ovlivňuje viditelnost z okna během nepříznivého počasí, například když voda negativně ovlivňuje výhled na boční zrcátka a dokonce i na přední a zadní sklo, což může být pro řidiče stresující a nebezpečné. Při návrhu aerodynamiky je důležité najít kompromis mezi designem, vlivem na hluk, součinitelem odporu a jasností při výhledu na boční zrcátka. Ověřování návrhu je možné urychlit pomocí simulace CFD a digitálních dvojčat, díky kterým lze činit důležitá rozhodnutí již v rané fázi návrhu a zabránit tak nákladnému přepracování návrhu po vytvoření prototypu. Díky tomu mohou výrobci realizovat nové inovativní nápady související s vodou a akustikou ještě před vytvořením prvního fyzického prototypu, což jim pomáhá snižovat náklady a urychlovat uvádění výrobků na trh.

Tento webinář se zaměří na interakci dešťové vody s návrhem externí aerodynamiky vozidla. Náš hostující přednášející Michael Ade ze společnosti Daimler představí výzvy, které simulace působení vodního živlu přináší, a prozradí, jak lze tyto faktory zohlednit během návrhu pomocí 3D výpočetní dynamiky kapalin (CFD), která zahrnuje vícefázové toky, například kapalné filmy, mlžení a usazeniny.

Naši odborníci vám ukáží, jak lze simulovat vnější působení vody na skutečném voze, včetně náročných detailů, jako je pohybující se stěrač. Aby mohli popsat veškeré relevantní jevy, využívají existujících vícefázových modelů v systému Simcenter STAR-CCM +, které si dále přizpůsobují a používají ve svých testovacích zařízeních. Prezentace představí současné možnosti a další možná vylepšení stávajících modelů, aby bylo možné co nejvěrněji předpovědět chování vody v aerodynamickém proudění kolem skutečného automobilu.