Improving cooling effectiveness of gas turbines through design space exploration

Improving gas turbine efficiency is essential for more economical operation. A significant way to enhance such capabilities is by increasing both the high-pressure turbine stage inlet and combustor exit temperatures. However, that can bring challenges to the internal components. Companies often spend many years studying and developing methods to improve the efficiency of turbine components, a process that is time-consuming and costly.

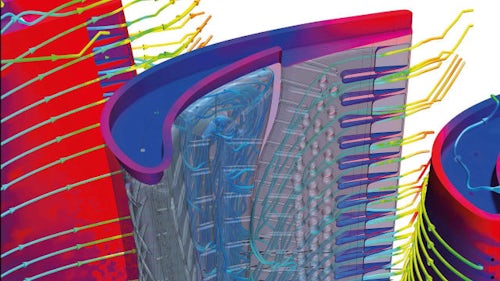

In this success story, you will learn how Kawasaki Heavy Industries (KHI) and B&B-Agema GmbH leveraged gas turbine computational fluid dynamics (CFD) designed with Siemens Solutions. By moving away from slow and iterative manual design space exploration process to a new and innovative automated process, KHI and B&B-Agema GmbH improved their gas turbine design by boosting efficiency and improving the cooling effectiveness by 200%!