S rostoucími očekáváními zákazníků je vysoká kvalita výroby naprosto nezbytná bez ohledu na to, kde se výrobky vyrábějí, distribuují a prodávají. Ověření norem kvality pomocí série zkušebních měření je zásadní součástí zajištění kvality (QA) ve výrobních týmech. V daných podmínkách výrobního prostředí musí testovací systémy kvality generovat spolehlivé výsledky levně a rychle, aby se usnadnila případná náprava problémů.

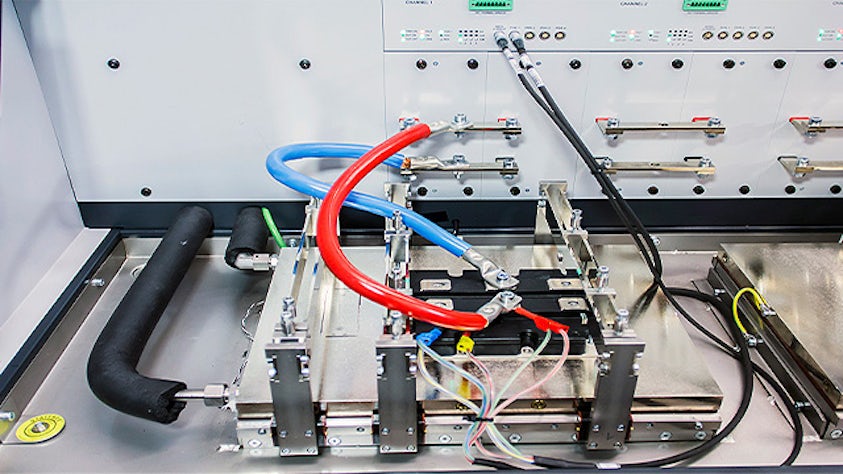

S naším řešením dosáhnete vysoké spolehlivosti testovacího zařízení, zkrátíte dobu cyklu, zvýšíte propustnost v sériové výrobě, zvýšíte úroveň automatizace díky snížení množství ručně prováděných úkonů a omezíte chyby obsluhy, spojíte objektivní a opakovatelné výsledky testů prošlo/selhalo s analýzou příčin, získáte tak přehled o možnosti změn návrhu a snadno se tak přizpůsobíte měnícím se požadavkům. Tím systematicky zlepšíte celkovou kvalitu výrobků, takže se sníží počet reklamací od zákazníků. Kromě toho se budete neustále zklepšovat díky hodnotným datům skutečné výroby a digitálního dvojčete výroby.

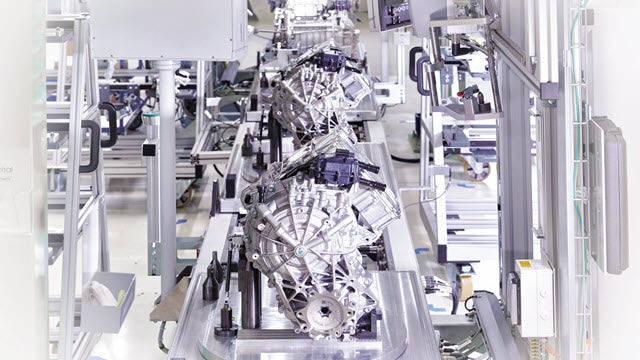

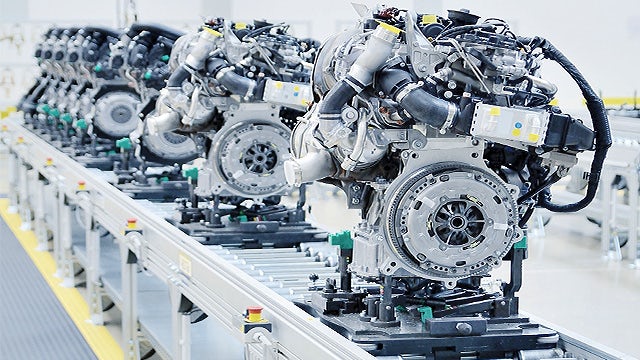

Zaveďte 100% systém kontroly kvality pomocí koncového testování

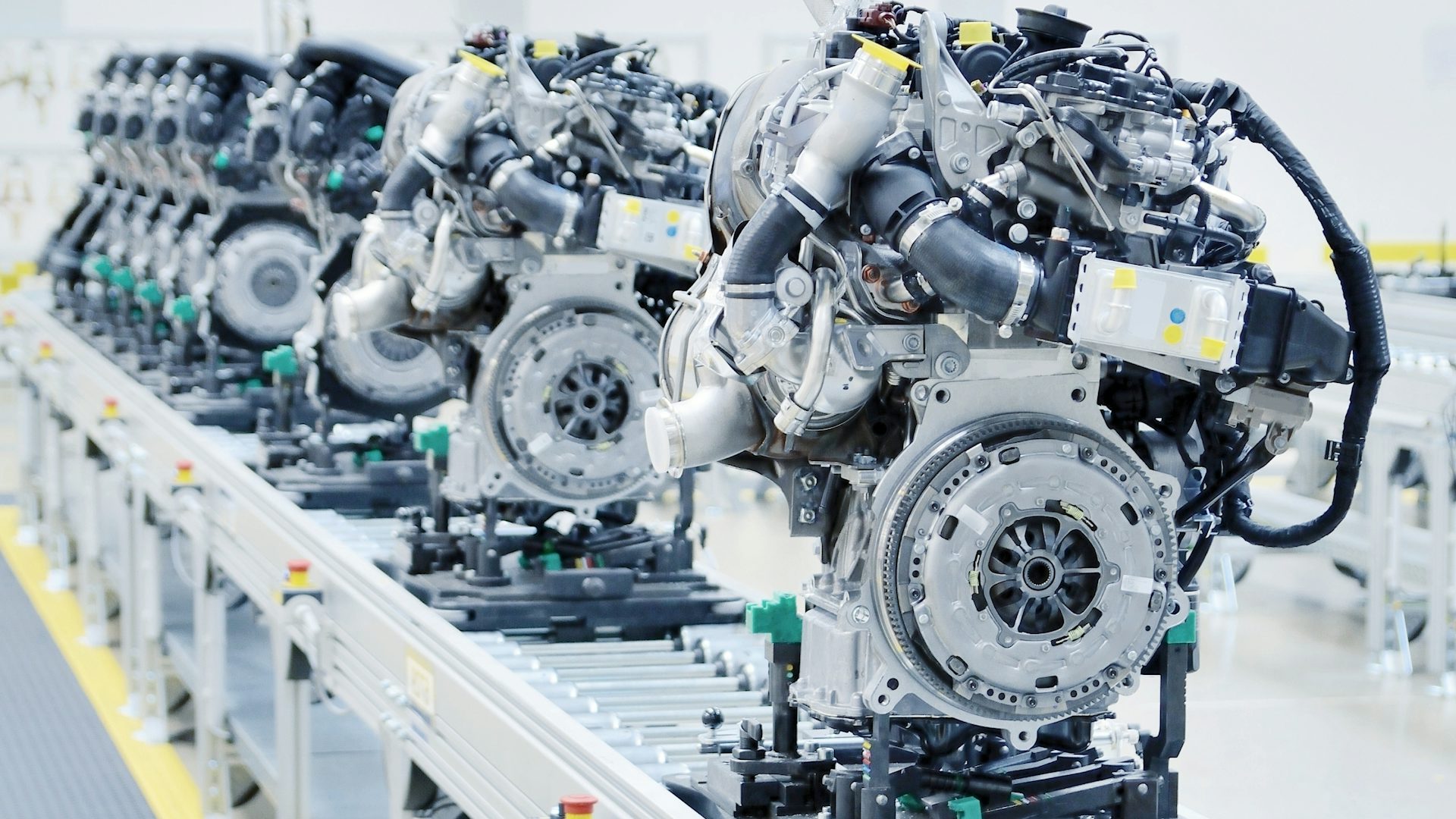

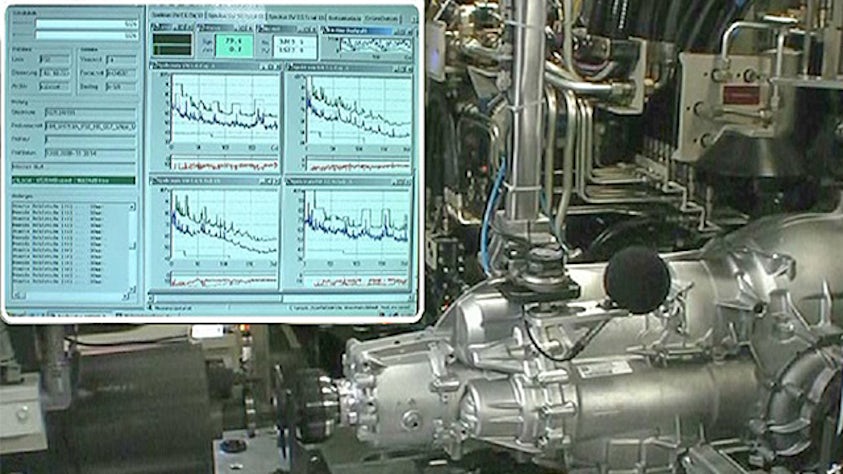

V automobilovém průmyslu se při koncovém testování používají vibroakustická měření k přesné identifikaci vlastností každé vyrobené součásti a určení, zda má výrobek nějakou vadu.