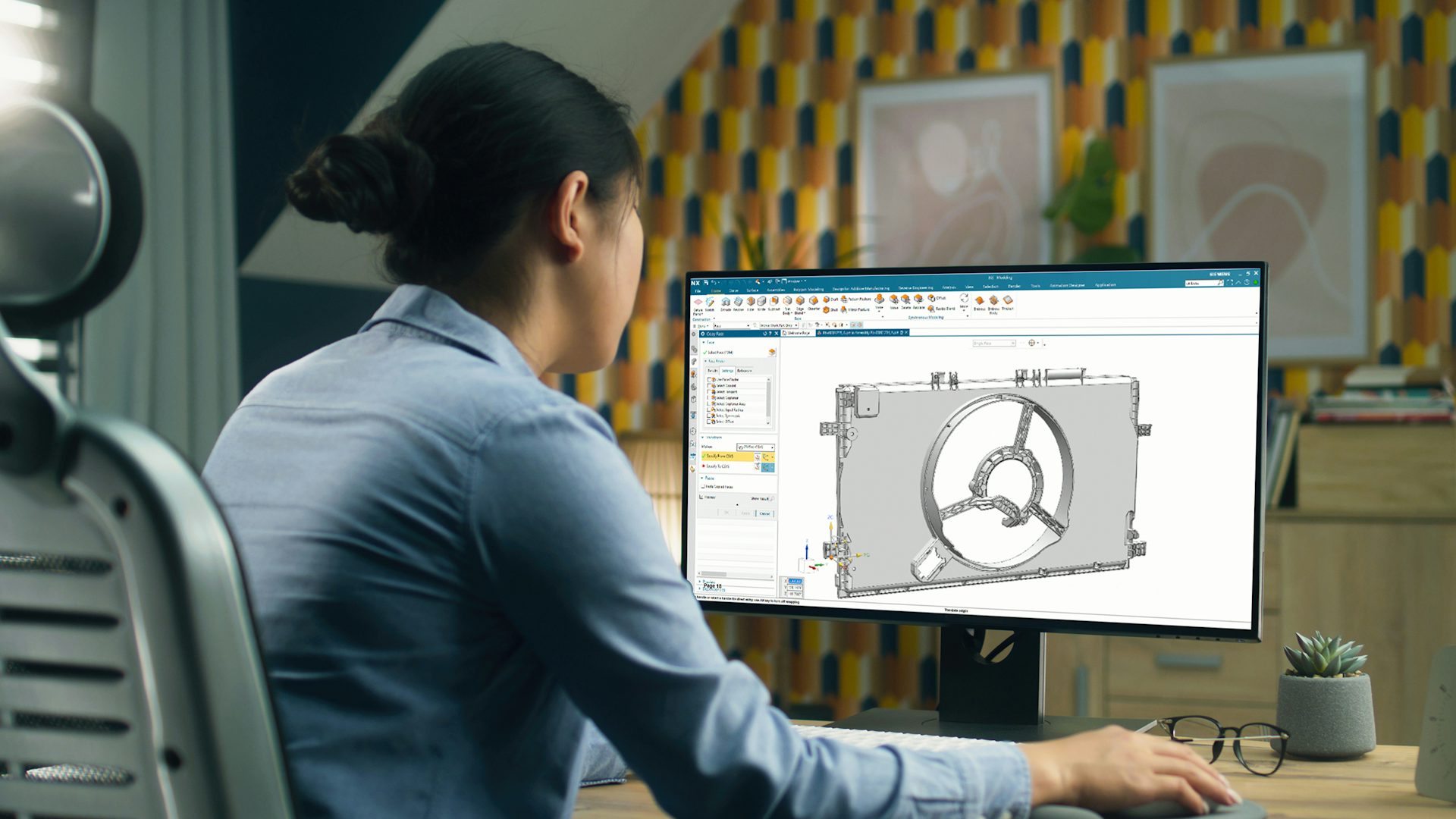

30-day free trial

Try NX X: Our SaaS CAD solution

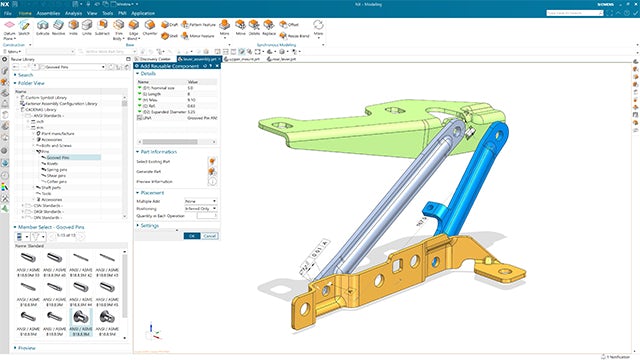

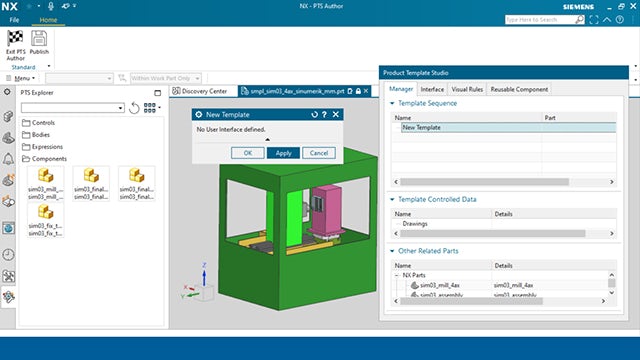

NX X is cloud SaaS NX, delivering the full power of NX design capabilities through three scalable seat options. NX X can be easily installed onto your devices for seamless connectivity. Built on NX architecture, you can continue to collaborate across disciplines with zero data loss—with confidence in secure data management capabilities.

Try before you buy by downloading a 30-day trial.

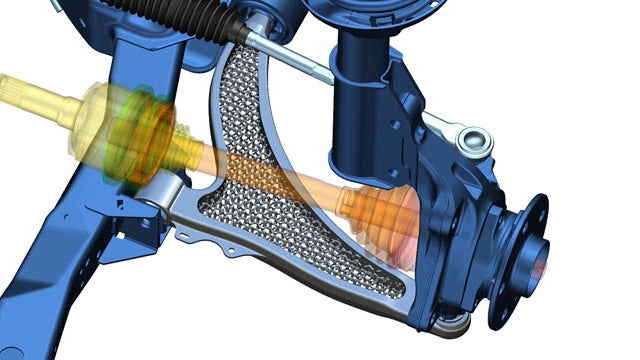

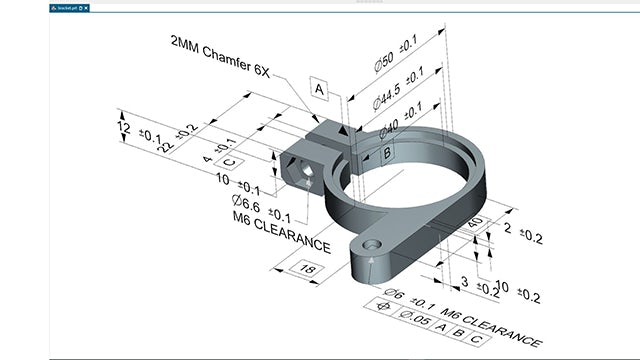

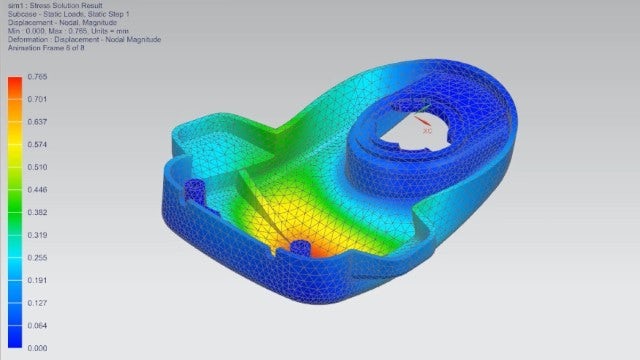

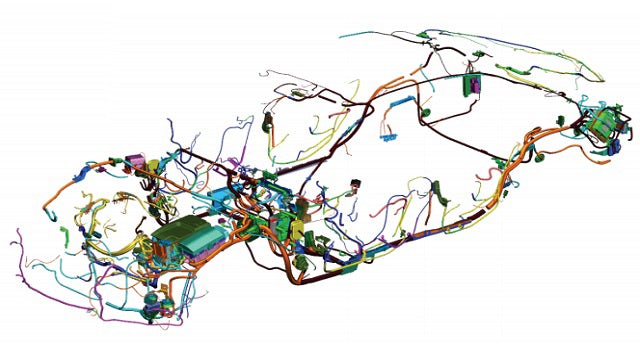

NX CAD mechanical design solutions

Deliver products quickly to market and right the first time. NX MCAD solutions enable you to use virtual models rather than costly physical prototypes.

Case study

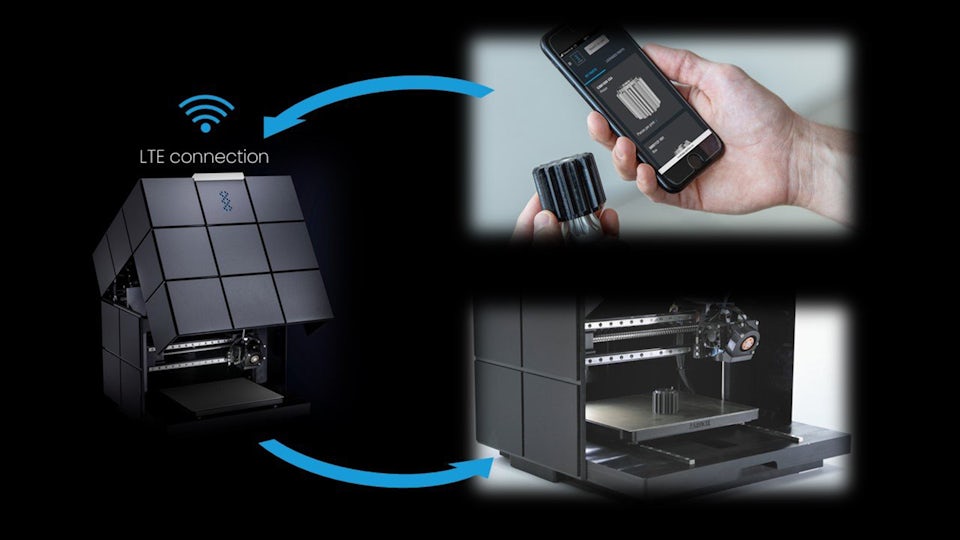

Schubert Additive Solutions

Case Study

Additive manufacturing system provider transforms part supply by designing industrial-grade 3D printer in a few weeks

Firma:Schubert Additive Solutions

Odvětví:Průmyslové stroje

Umístění:Crailsheim, Germany

Additive Manufacturing Network, NX