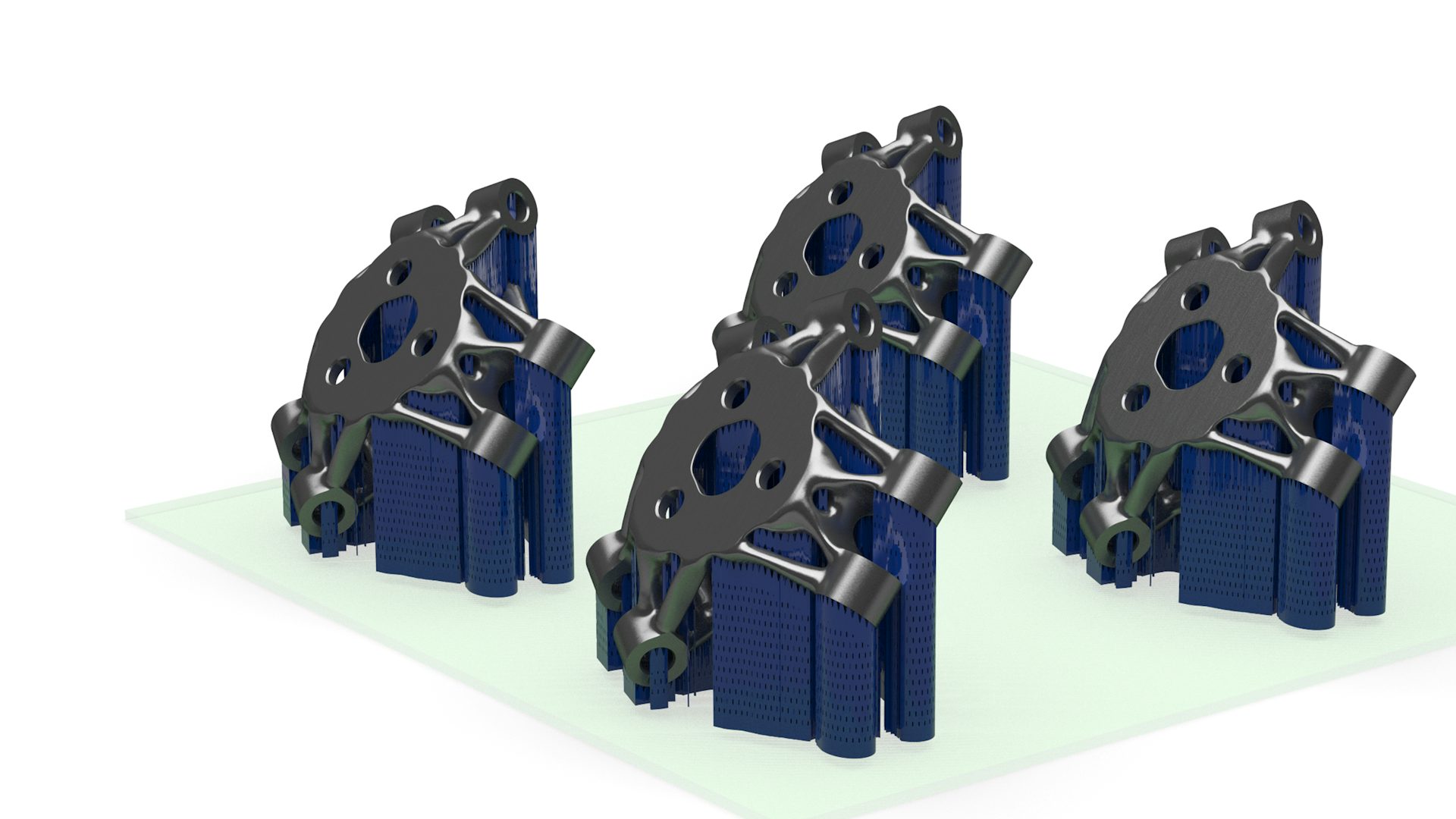

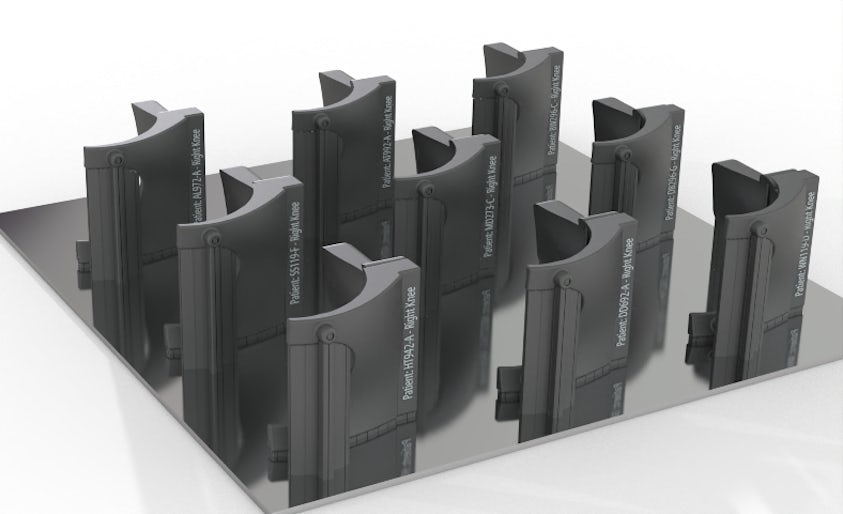

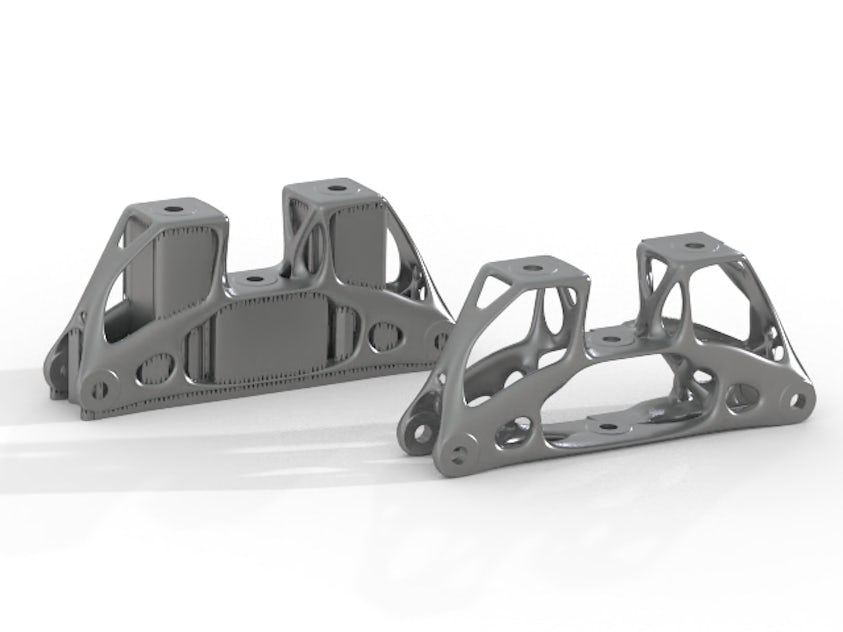

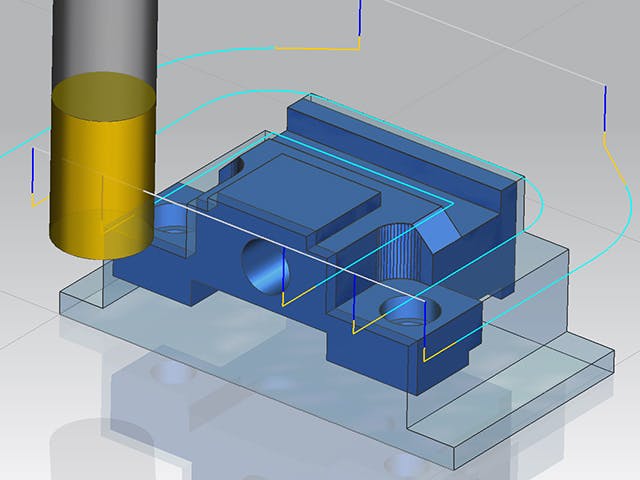

Umístění a skládání dílů

Tiskněte díly efektivně s úplnou kontrolou polohy dílu a automatizovaným, efektivním skládáním v rámci sestavovacího objemu. Proto řešení NX poskytuje integrované nástroje pro efektivní vyplňování sestavovacího zásobníku. Ať už umisťujete díly ručně, nebo automaticky pomocí integrovaného 2D a 3D skládání, řešení NX vám dává plnou kontrolu nad dosahováním cílů v oblasti efektivity a kvality.