Navrhujte lepší továrny a linky rychleji

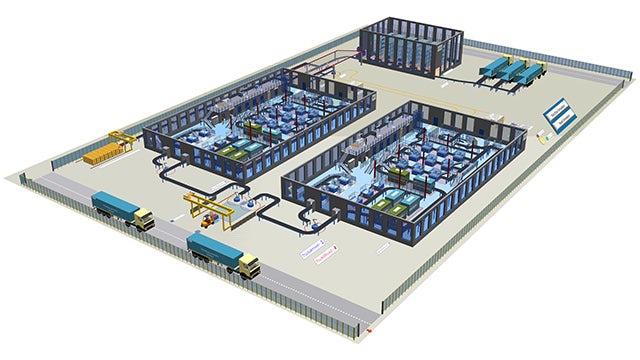

Umožňuje přesnou analýzu dopadů a efektivní správu změn pro rozvržení továrny, rozvržení linky a návrhy zařízení přímo spojené s plány výrobních procesů.

Vytvářejte požadované upínky, nástroje a zařízení pomocí klasifikované knihovny parametrických zdrojů integrované s plánováním výroby a návrhem továrny, abyste rychleji dosáhli lepšího rozvržení výroby.

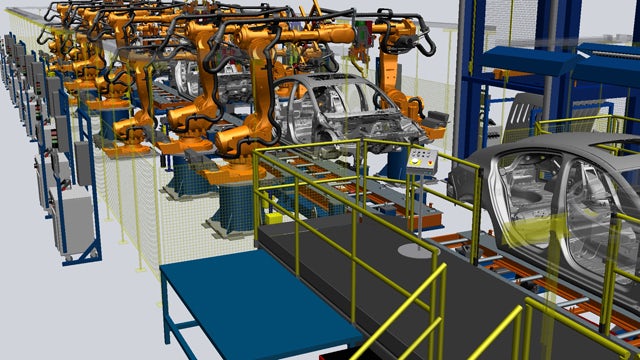

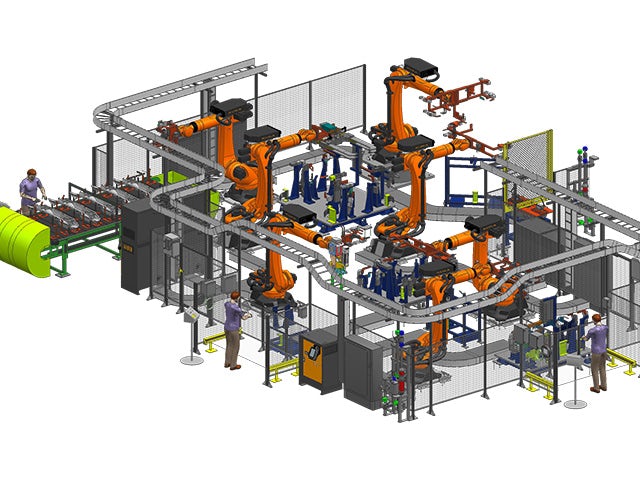

Ověřujte a optimalizujte návrhy továrních linek

Pomocí simulačního softwaru přímo v prostředí pro plánování linek můžete plně ověřit a optimalizovat své návrhy továren a rozvržení výroby.

Simulujte úkony včetně robotů, nástrojů, zařízení pro manipulaci s materiálem a pracovníků na úrovni podrobných stanic, linek nebo továren, abyste optimalizovali umístění automatizace a zařízení, ergonomické požadavky, strategii dodávek materiálu a rychlost výroby.

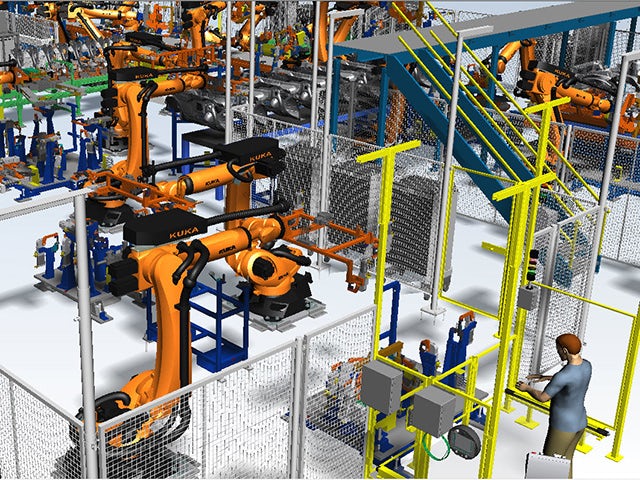

Uvádějte výrobní linky do provozu ve virtuálním prostředí

Využijte technologii simulace hardwaru ve smyčce (HiL) a softwaru ve smyčce (SiL) k virtuálnímu uvedení sestavovacích linek a zařízení do provozu během instalace a před zahájením výroby

Otestujte řídicí logiku a rozhraní mezi mechanickým a elektrotechnickým inženýrstvím pomocí skutečného řídicího systému a digitálního dvojčete k virtuálnímu ověření fungování systémů manipulace s materiálem a rozvržení výroby.

Procházejte továrny kdekoli a kdykoli

Získejte přístup k digitálním dvojčatům svých výrobních provozů v cloudu, která jsou uvedena v geografickém kontextu. Procházejte podniky jednoduchým a známým způsobem s intuitivním přístupem k informacím z jakéhokoli IT systému.

Usnadněte virtuální prohlídku svých továren pomocí bohatých vizualizačních nástrojů a technik s možností získat relevantní informace a alternativní úhly pohledu pouhým kliknutím na vizuální značky.

Ford Motor Company

Automobilka ukazuje, jak zjednodušený návrh sestavovací linky pomáhá propojit různé systémy a zvýšit efektivitu nákladů ve výrobě.

Společnost Ford automatizuje návrh rozložení továrny

Společnost: Ford Motor Company

Odvětví: Automobilový průmysl a doprava

Umístění: Velká Británie

Software společnosti Siemens: NX Line Designer, Teamcenter Manufacturing