Získejte konkurenční výhodu s pokročilou automatizací návrhu

Návrh kabelových svazků

Konstruktéři kabeláže mohou efektivně zaznamenat svůj konstrukční záměr a rychle a přesně vytvářet maximálně podrobné a ověřené návrhy kabeláže.

Konstrukční řešení kabeláže

Software Capital nabízí automatizované inženýrské, validační a informační funkce pro práci s kabeláží, které umožňují technikům navrhujícím kabeláž efektivně připravovat produktová data.

Cenová kalkulace kabeláže

Cenová kalkulace kabeláže umožňuje inženýrům vytvářet komplexní modely, které zajišťují realistické stanovení nákladů a přesné nabídky.

Software Capital pomáhá inženýrům snižovat náklady a zlepšovat kvalitu

Zkraťte dobu zavádění nových produktů využitím kontinuity digitálních dat a opakovaného využití duševního vlastnictví. Optimalizujte návrhy a zlepšete kvalitu produktů pomocí automatizace a simulace s technologií digitálních dvojčat.

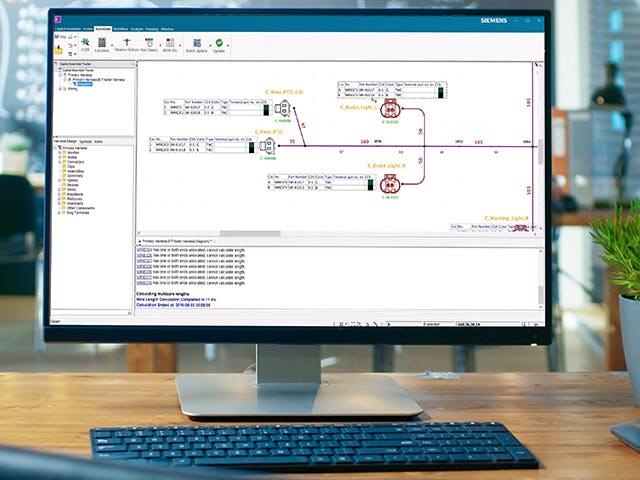

Modelování nákladů, které chrání duševní vlastnictví

Je nezbytné, aby kabelové svazky mohly být vyráběny za konkurenceschopné a snadno pochopitelné náklady. To je však velmi složitý úkol, jelikož časové harmonogramy projektů se zkracují, marže výrobců se snižují a proměnné, jako jsou obsah návrhu a cena mědi, se naopak velmi rychle mění. Je to úkol, jehož dynamika přesahuje chápání jednoduchých metod výpočtu nákladů. Software Capital nabízí optimální, účelové řešení, které automatizuje kalkulaci nákladů a poskytuje formální rámec a proces pro rychlé generování přesných nákladů na materiál a práci.

Software Capital zahrnuje plně rozšiřitelné funkce modelování nákladů, které chrání duševní vlastnictví a umožňuje technikům provádějícím kalkulace nákladů vytvářet komplexní modely. Tyto modely zachycují potřebné detaily, aby bylo zajištěno, že realistické generování nákladů vytváří přesné nabídky. Data se stávají „digitálním vláknem“, které umožňuje spotřebovávat nákladové modely a znovu je používat souvisejícími nástroji ve sledu jednotlivých výrobních kroků.

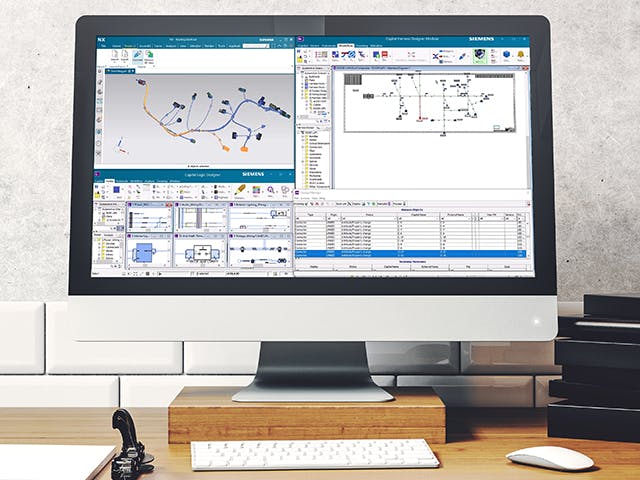

Výkonné grafické prostředí pro návrh kabeláže

Konstruktéři kabeláže musí vytvořit maximálně podrobný výkres, který přesně zachycuje a popisuje záměr konstrukčního návrhu a požadavky na kabeláž. Software Capital podporuje všechny nezbytné činnosti spojené s návrhem kabeláže při zachování digitální kontinuity. Umožňuje společnostem přizpůsobit nástroj a procesní tok tak, aby vyhovovaly jejich potřebám, a to jak z hlediska grafických výstupů, tak zpráv.

Software Capital nabízí výkonné grafické prostředí pro návrh kabeláže, které umožňuje automatizovaný návrh a validaci jednotlivých kabelových svazků. Konstruktéři kabeláže mohou efektivně zaznamenat a popsat svůj konstrukční záměr a vytvářet maximálně podrobné a ověřené návrhy kabeláže (schémata a data). Inženýři mohou také definovat pravidla a omezení, aby usnadnili komplexní automatizaci konstrukčního návrhu a zajistili konzistenci.

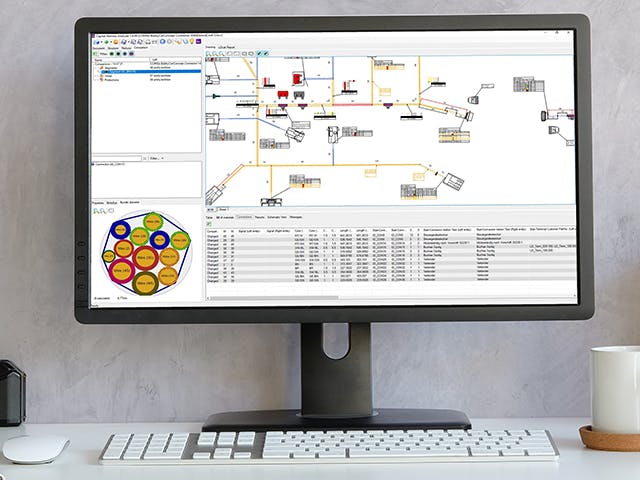

Automatizované konstrukční řešení kabeláže

Konstrukce kabeláže musí být rozšířeny o příslušné podrobnosti, jako jsou informace o součástech kabeláže a množství materiálu potřebné pro následnou spotřebu prostřednictvím stanovení nákladů a výrobního technického řešení. Cílem konstruktérů je plně definovat konstrukční data, aby bylo dosaženo úplné a přesné definice kabeláž a extrahovat a dodat související dokumentaci. Automatizované technické řešení, validace a informace o kabeláži umožňují technikům efektivně připravovat produktová data pro kalkulaci nákladů a výrobní technické úkoly.

Postupy výběru součástí umožňují automatický a přesný výběr kompatibilních dílů a vytvářejí tak vylepšená data o kabeláži pro kalkulaci nákladů a výrobu. Automatizované porovnání konstrukčních návrhů umožňuje identifikaci grafických a specifikačních změn mezi jednotlivými revizemi produktu. Automatizovaná technická funkce vypočítává přesné množství materiálu a popisuje tak hotový výrobek.

Navrženo pro podporu standardu KBL

Software Capital také zahrnuje přední sadu aplikací pro návrh elektroinstalačních systémů a vývoj kabeláže založených na standardu KBL.

KBL, standard výměny dat používaný německým automobilovým průmyslem, se používá v hlavních odděleních vývoje mnoha společností, zejména v prémiovém německém automobilovém sektoru. Software Capital zahrnuje sadu produktů založenou na tomto standardu a sahá od importu první logické koncepce systému přes kompletní kabelovou sadu až po výrobu a kalkulaci nákladů.