Propojená výroba pro podporu vašeho podnikání

Dostaňte se do výroby rychleji díky plánování výrobních procesů a správě dat řešení Teamcenter. Spolupracujte okamžitě a bezpečně na optimalizaci výroby dílů a úkonů sestavování. Provádějte všechny související činnosti efektivněji pomocí digitálního vlákna, které propojí vaši společnost i závody.

Správa výrobních procesů v cloudu

Správa výrobních procesů typu SaaS je k dispozici v cloudu a spravují ji pro vás odborníci ze společnosti Siemens. Začněte hned s předem nakonfigurovanými osvědčenými postupy. Získejte kontinuitu výrobních informací díky zabezpečené výměně dat a viditelnosti procesů. Propojte své inženýrské a výrobní inženýry, projektanty, pracovníky v dílně, partnery a dodavatele, konstruktéry linek, návrhové týmy a další.

Snadno plánujte a spravujte své výrobní procesy

Vytvářejte a spravujte data výrobních kusovníků (MBOM) a kusovníků procesů (BOP), abyste pochopili, co a jak vyrábět. Řešení Teamcenter ve spojení s digitálními výrobními řešeními společnosti Siemens usnadňuje spolupráci mezi inženýringem, výrobou a realizací. Opakovaně používejte úkony sestavování napříč závody, vytvářejte a sdílejte pracovní pokyny v dílně, provádějte analýzu času a vyvažování linek a další.

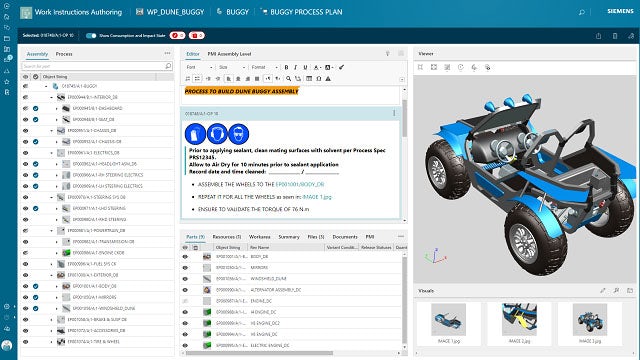

Vytváření a sdílení elektronických pracovních pokynů

Vytvořte podrobné výrobní pokyny, čímž zvýšíte jasnost procesů a dílčích kroků v dílně. Poskytujte nejaktuálnější informace a jasně předveďte seznam procesních kroků pomocí nástrojů pro vizualizaci 2D a 3D a technologie rozšířené reality. Procesní dokumentace je automaticky aktualizována prostřednictvím správy revizí, takže můžete rychle a snadno reagovat na změny, a to jak před výrobou, tak během ní.

Vytvoření a údržba kusovníku procesů

Vytvořte procesy a úkony v rámci kusovníku procesů pro posloupnost kroků v plánech sestavování. Přiřaďte příslušné díly a sestavy z MBOM k operacím, specifikujte požadované nástroje a zdroje z kusovníku zařízení (BOE) nebo prostřednictvím knihovny klasifikovaných objektů. Zjednodušte změny z inženýringu výrobků na kusovník procesů pomocí nástrojů pro kontrolu odpovědnosti, abyste zachovali synchronizaci inženýrství a výroby.

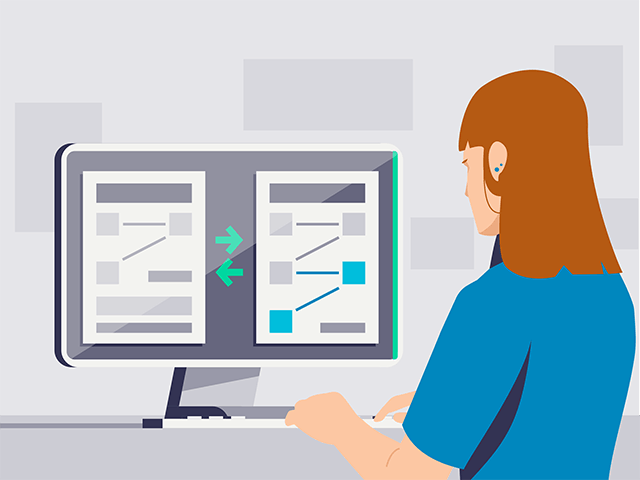

Snadné sladění technických a výrobních kusovníků

Rychle aktualizujte plány procesu sestavování podle změn v návrhu pomocí integrované platformy pro vývoj výrobků a procesů v řešení Teamcenter. Nástroje pro kontrolu odpovědnosti za kusovník pomáhají produktovým a výrobním inženýrům rychle vizualizovat a ověřit dopad jakýchkoli změn výrobků a procesů. Tím se zabrání nákladné identifikaci problémů ve výrobě v pozdní fázi.

Odhad provozních časů a vyvažování linky

Řešení pro správu času a vyvažování poskytují přehled o činnostech výrobního procesu s přidanou a nepřidanou hodnotou. Časová analýza používá časové standardy, jako je MTM, s integrací do řešení TiCon. Vyvážení linek zobrazuje vizuální shrnutí času pro provozy, stanice a obsluhu. Optimalizujte plán na cílový čas taktu, zlepšete práci obsluhy na lince a vyhodnoťte alternativní plány.

Optimalizujte plánování výroby pomocí výroby dílů

Přeměňte svou strojní dílnu na provoz spravovaný daty s informacemi o návrhu výrobků a plánování sestavování v jednom systému. Optimalizujte své výrobní procesy pomocí plánování dílů, připojení k dílně a knihovny výrobních zdrojů.

Digitální správa výrobních zdrojů

Rychle najděte to, co potřebujete, a efektivně spravujte své výrobní prostředky pomocí výkonných možností vyhledávání a načítání v rámci celého klasifikačního systému. Díky předem nahraným údajům o obráběcích nástrojích je knihovna výrobních zdrojů (MRL) přístupná přímo z řešení NX CAM. Můžete vytvářet nástrojové sestavy nebo importovat data z katalogů dodavatelů nástrojů.

Připojení k dílně

Využijte jedinou platformu pro propojení plánování a výroby. Předávejte správná data přímo do výrobního zařízení včetně CNC strojů, CMM a robotů. Komunikujte o svých kompletních plánech výrobního procesu napříč funkčními odvětvími. Ujasněte si, co, jak a kde se výrobky vyrábějí. Ujistěte se, že všechny zúčastněné strany vědí, jaké zdroje jsou potřeba.

Next-generation collaboration with Teamcenter Share

Optimize your production and manufacturing processes with Teamcenter Share, a cloud-based collaboration solution with a seamless connection to Teamcenter Easy Plan software. Extend the reach of manufacturing planning-related data and processes beyond your internal teams to work smarter and accelerate innovation.