Začněte s integrací. Udržte si integraci.

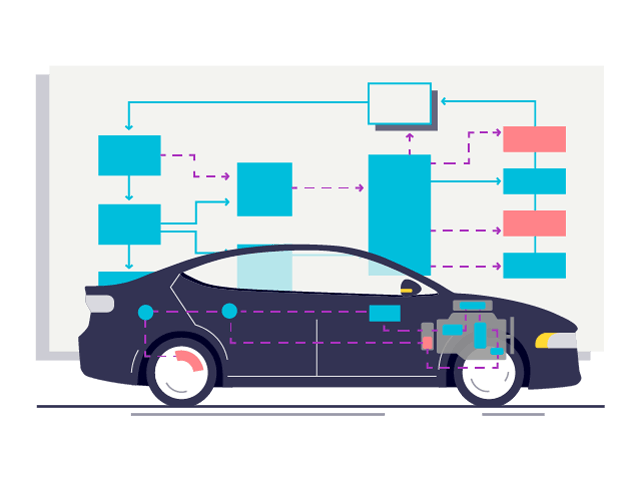

Integrujte architekturu výrobků do systémových modelů, požadavků a parametrů v rámci systému pro správu životního cyklu výrobků (PLM), abyste měli celý proces vývoje výrobků pod kontrolou.

Vytvářejte systémové modely se standardní metodikou

Zastavte nákladný cyklus návrhu a sestavení specifikací orientovaných na dokumenty pomocí spolupráce při vytváření integrovaných plánů výrobků. Systémové modelování, vedené standardní systémovou metodikou ISO, zachycuje architekturu výrobků, rozhraní, požadavky a parametry na jednom místě. Integrace do systému PLM nastaví proces tak, aby umožňoval nepřetržitou integraci.

Správa architektury výrobků pomocí standardních služeb systému PLM

Představte si nakonfigurovaný parametr, který se vrací zpět k rozhodnutí o architektuře. Systémové modelování s parametry, funkcemi a rozhraními se podílí na službách systému PLM, jako jsou konfigurace, změny a pracovní postupy. Může s tím souviset také obchodní studie spojená s požadavky a navazující na díly, dodavatele, simulace, procesy, testování a další.

Nepřetržitá spolupráce s dodavateli založená na modelech

Využijte služby pro spolupráci dodavatelů ke sdílení částí systémových modelů s dodavateli a současně chraňte své duševní vlastnictví prostřednictvím integrované architektury v rámci souladu se systémem PLM a řešením SysML v2. Dodavatelé mohou průběžně poskytovat zpětnou vazbu o pokroku v rámci integrace a vytvářet tak řetězce návrhu založené na modelech (MBDC).

Try systems engineering for Aerospace & Defense

Start your trial in minutes and learn to build your own sophisticated aerospace model-based systems engineering solution. Integrate the resulting design by collaborating across suppliers and the internal organization, with no installation required. We create the environment for you!

Take a trial run in systems engineering for Automotive

Start your trial in minutes and learn to build your own sophisticated automotive model-based systems engineering solution. Integrate the resulting design by collaborating across suppliers and the internal organization, with no installation required. We create the environment for you!