Správa servisních aktiv (SAM) je kritický systém v rámci řešení správy životního cyklu služeb (SLM), který zase podporuje komplexní správu životního cyklu produktu (PLM).

Software pro správu servisních aktiv slouží jako zdroj dat, který komplexně popisuje fyzický majetek od jeho schválených konfigurací až po jeho provozní stav. Tyto znalosti aktiv a služeb zajišťují přesné jádro správy konfigurace, které umožňuje, aby všechny ostatní systémy správy životního cyklu služeb byly řízeny konfigurací aktiv a produktů. Servisní a produktové týmy používají správu servisních aktiv k přístupu, zobrazení a využití zabezpečeného a jediného integrovaného zdroje informací. Správa aktiv služeb, označovaná také jako správa fyzických prostředků, udržuje skutečnou konfiguraci a data o výkonu provozního prostředku a jeho podkladových systémů, subsystémů a komponent. Servisní týmy používají software pro správu servisních aktiv k určení toho, které díly lze použít k co nejrychlejšímu vyřešení servisní události. Využívají také správu aktiv služeb k vyhodnocení dopadů navrhovaných změn založených na produktu nebo službě; Mohou posoudit plný dopad těchto změn na provozní vlastnosti. Výsledky servisních činností jsou zaznamenávány prostřednictvím správy servisních aktiv a napájejí tak systém s uzavřenou smyčkou, který umožňuje neustálé zlepšování produktů a služeb.

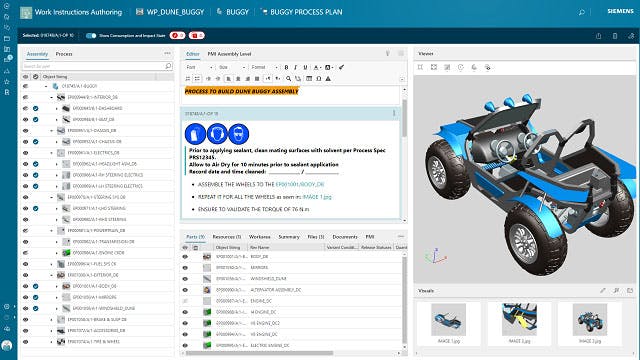

Související produkty: Teamcenter