Konfigurace fyzických aktiv zahrnuje všechny mechanické, elektrické/elektronické, softwarové a související součásti aktiv související s dokumenty, jakož i historii změn konfigurace během jejich provozního používání. Data konfiguraci fyzických aktiv mohou zahrnovat technickou dokumentaci potřebnou pro servisní činnosti a informace o servisních materiálech, jako jsou díly a sady.

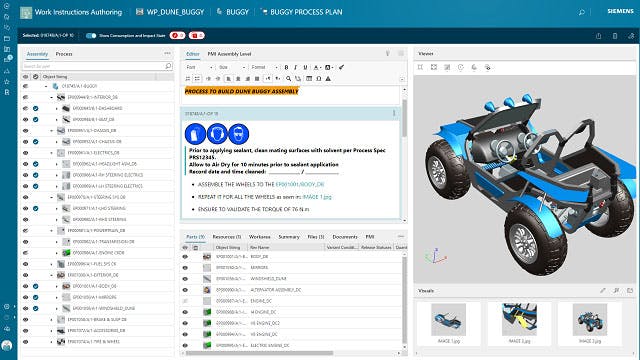

Účelem vytváření a sledování konfigurací fyzických aktiv je zjednodušit proces podpory a servisu výrobků s vysokou hodnotou v terénu. Software pro správu fyzických aktiv spravuje komplexní síť informací spojených s konfigurací fyzických aktiv, snižuje náklady a čas potřebný k vytvoření a dodání dokumentace pro kritický servis a zároveň zlepšuje kvalitu a efektivitu informací. Prostřednictvím softwaru pro správu fyzických aktiv mají všechny zúčastněné strany jistotu, že získají aktuální přehled o konfiguraci servisovaných fyzických aktiv.

Konfigurace fyzických aktiv je také kritickou sadou informací používanou softwarem pro správu životního cyklu servisování k zajištění včasného a správného servisu výrobků během jejich provozní životnosti. Funkce správy servisních aktiv tohoto softwaru poskytují otevřený ekosystém, který zpřístupňuje konfigurace fyzických aktiv výrobcům OEM, zákazníkům a třetím stranám, které se podílejí na poskytování efektivního servisu pro spravovaná aktiva.

Je důležité mít přesné záznamy o konfiguracích fyzických aktiv pro široké spektrum vyráběných výrobků, ale zejména pro složité výrobky s relativně dlouhými životními cykly: vybavení, stroje, zařízení, vozidla a další. U mnoha z těchto výrobků se výrobní portfolia v posledních letech rozrostla o velké množství variant výrobků, včetně různých fyzických konfigurací a geometrií, různých konfigurací softwaru a hardwaru, různých komponent a sestav a dalších variací. Aby bylo možné tato aktiva řádně servisovat po celou dobu jejich provozní životnosti, konfigurace fyzických aktiv sleduje dané aktivum a aktualizuje konfiguraci prostřednictvím instalace, zavedení, údržby, oprav a upgradů.

Související produkty: Teamcenter