Simulace robotiky je digitální nástroj používaný k navrhování automatizovaných výrobních systémů založených na robotice. Funkčně simulace robotiky využívá digitální reprezentaci – digitální dvojče – k umožnění dynamické interakce s robotickými modely ve virtuálním prostředí. Cílem robotických a automatizačních simulačních systémů je rychlejší uvedení automatizačních systémů do provozu a zahájení výroby s menším počtem chyb než konvenční automatizační technika.

Simulace automatizace hraje v robotice klíčovou roli, protože umožňuje experimentování, které je nákladné a časově náročné provádět na skutečných robotech – a ještě více provádět experimenty ve výrobě. Simulace robotiky umožňuje inženýrům zkoušet nápady a vytvářet výrobní scénáře v dynamickém virtuálním prostředí a shromažďovat data virtuální odezvy, která přesně reprezentují fyzické odezvy řídicího systému.

Simulace robotiky se neustále vyvíjí, aby udržela krok s rostoucími schopnostmi průmyslových robotů. Roboti jsou nasazováni do dynamických prostředí, kde se úkoly robota často mění nebo zahrnují lidské spolupracovníky. Poptávka po pokročilé robotice stále roste, protože výrobci zvyšují složitost, rozmanitost a přizpůsobení produktů, aby uspokojili poptávku zákazníků. Pokročilá robotika zahrnuje rozhodování za běhu, reaktivní programování pro nepředvídané události a schopnost přizpůsobovat se a zlepšovat se na základě dat shromážděných průmyslovým internetem věcí (IIoT) zpracovaným umělou inteligencí (AI). Úroveň složitosti programování pokročilé robotiky a nasazování a provoz pokročilých robotů, stejně jako vysoké náklady, které by byly vynaloženy na ladění robotického systému ve výrobě, činí z pokročilé simulace robotiky kritickou součást výrobního inženýrství.

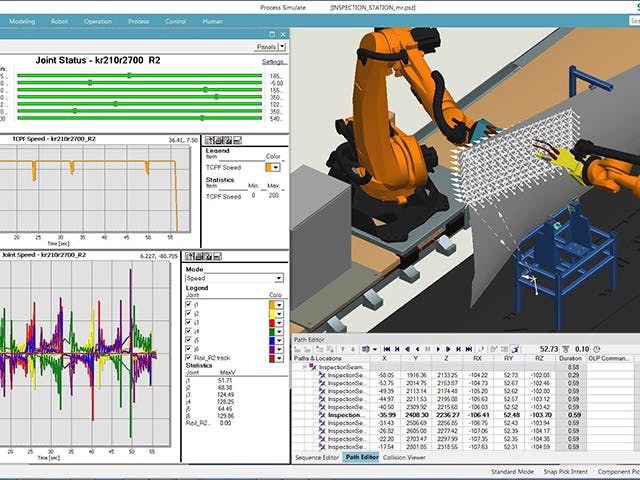

Pokročilý software pro simulaci robotiky umožňuje uživatelům navrhovat a optimalizovat robotickou výrobu, což zahrnuje novou flexibilitu a přizpůsobení umožněné pokročilými robotickými technologiemi. Inženýři mohou využít pokročilou robotickou simulaci k návrhu kompletních 3D robotických pracovních buněk a poté ověřit a optimalizovat sekvence výrobního procesu simulující realistické chování a reakce. Mohou digitálně ověřovat koncepty automatizace a provádět pokročilé programování robotiky offline. Tento simulační software také umožňuje společnostem virtuálně uvést do provozu kompletní výrobní zařízení.

Související produkty: Plánování a simulace robotiky | Simulace procesu Tecnomatix