CERTIA reduces test rig development time by 25 percent and increases the availability rate of the physical testing platform by 60 percent using Simcenter Amesim

Siemens Digital Industries Software solution prepares firm to develop virtual designs of intelligent test rigs

CERTIA

CERTIA designs and produces test rigs. The Paris-based company was founded in 1987, and is a test bench supplier for the aeronautical and automotive industries.

http://www.certia.fr- Headquarters:

- Paris, France

- Products:

- Simcenter Products, Simcenter Amesim

- Industry Sector:

- Aerospace & defense

Having a virtual platform has become an absolute necessity. We have to be ready and anticipate requests from customers like Airbus to do testing in a common virtual environment.

CERTIA

Enhancing the test bench

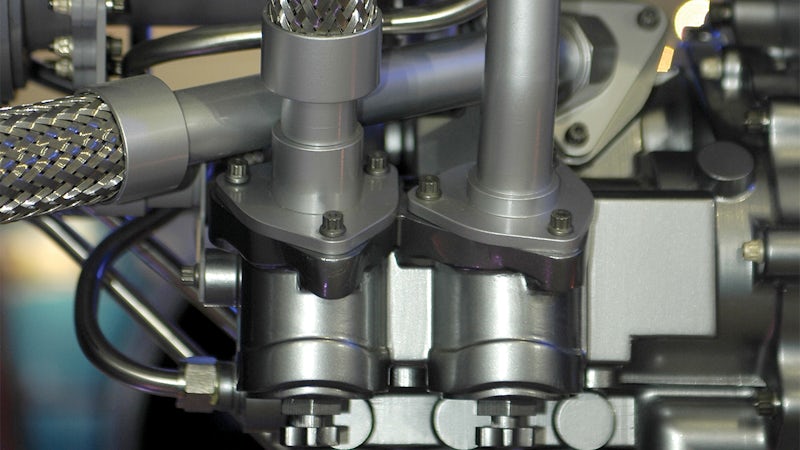

Physical test benches are an indispensable part of the aircraft development process. The big challenge for a test rig is to replicate the extreme conditions that aircraft must be able to withstand as well as create a specific test setup in which the material, component or assembly in question can be put through these exceptional circumstances.

CERTIA specializes in the design and production of test rigs. The Paris-based company was founded in 1987, and is a test bench supplier for the aeronautical and automotive industries. It counts Airbus France, the Safran Group, Air France Industries, PSA Peugeot Citroën and Renault among its customers.

In recent years, CERTIA has started using Simcenter Amesim software from Siemens Digital Industries Software to assist engineers in test rig development. The platform helps develop- ers choose the appropriate components to make sure that the test bench functions properly.

“In the past, we had many problems with our test benches,” says Achour Debiane, head of the automation department at CERTIA. “What was especially difficult was to reproduce aeronautical loads and to make sure that the test rigs would reach the projected performance. Because of these difficulties, it was clear that our test bench concept needed to change.”

Saving time

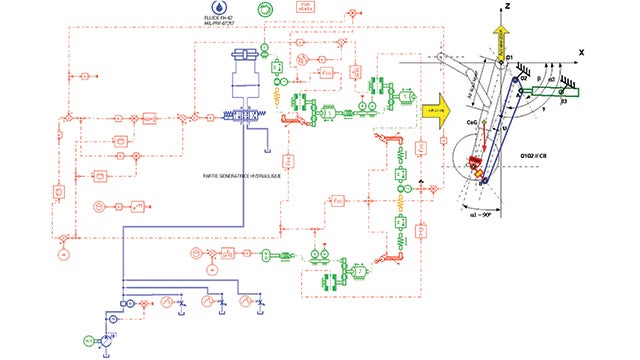

CERTIA opted for Simcenter Amesim for two reasons: first, because of its hydraulic solutions, and second, because of its multi-physical simulation capabilities. Using Simcenter Amesim software has proven especially valuable in the early stages of the design process.

“During the feasibility studies of hydraulic systems, Simcenter Amesim has saved us a lot of time and programming effort because it is no longer necessary to work on time-consuming equations,” says Debiane. “In the aeronautical field, planning cycles are very short. As a supplier for a large organization, it is very important for us to do the feasibility studies as quickly as possible.”

Besides shorter design cycles, another benefit of using 1D modeling in the concept phase is that it helps optimize the behavior and dynamic characteristics of the various test rig components. The simulation results are vital for the mechanical integration of the test rig and help validate the design by virtually verifying the stiffness, inertia and masses of the test bench. Very early in the development cycle, simulation is used to determine test rig viability and eliminate the need to change mechanical parts in the final stages.

“Thanks to Simcenter Amesim, we managed to reduce test rig development time by 25 percent; and because we were able to perform part of the tests via simu- lation, the availability rate of the physical testing platform increased by approxi- mately 60 percent,” says Debiane.

Anticipating the future

“Having a virtual platform has become an absolute necessity,” says Debiane. “We have to be ready and anticipate requests from customers like Airbus to do testing in a common virtual environment, so suppliers will need to be able to interface with OEMs (original equipment manufacturers). This will be the way of working in the future.”

Siemens Digital Industries Software has helped launch CERTIA into the world of simulation inno- vation and is helping to prepare the company to perform the virtual design of intelligent test rigs. Mechatronics engi- neering and intelligent system simulation are sweeping the aeronautical industry; and in this virtual revolution, test bench design is a key factor to success.

Thanks to Simcenter Amesim, we managed to reduce test rig development time by 25 percent; and because we were able to perform part of the tests via simulation, the availability rate of the physical testing platform increased by approximately 60 percent.

CERTIA