Customers demand complex, high-quality and sustainable products that are delivered fast. To stay competitive, you must develop and release innovative designs that meet the needs of a changing market in less time, at premium quality, with fewer issues and at competitive prices.

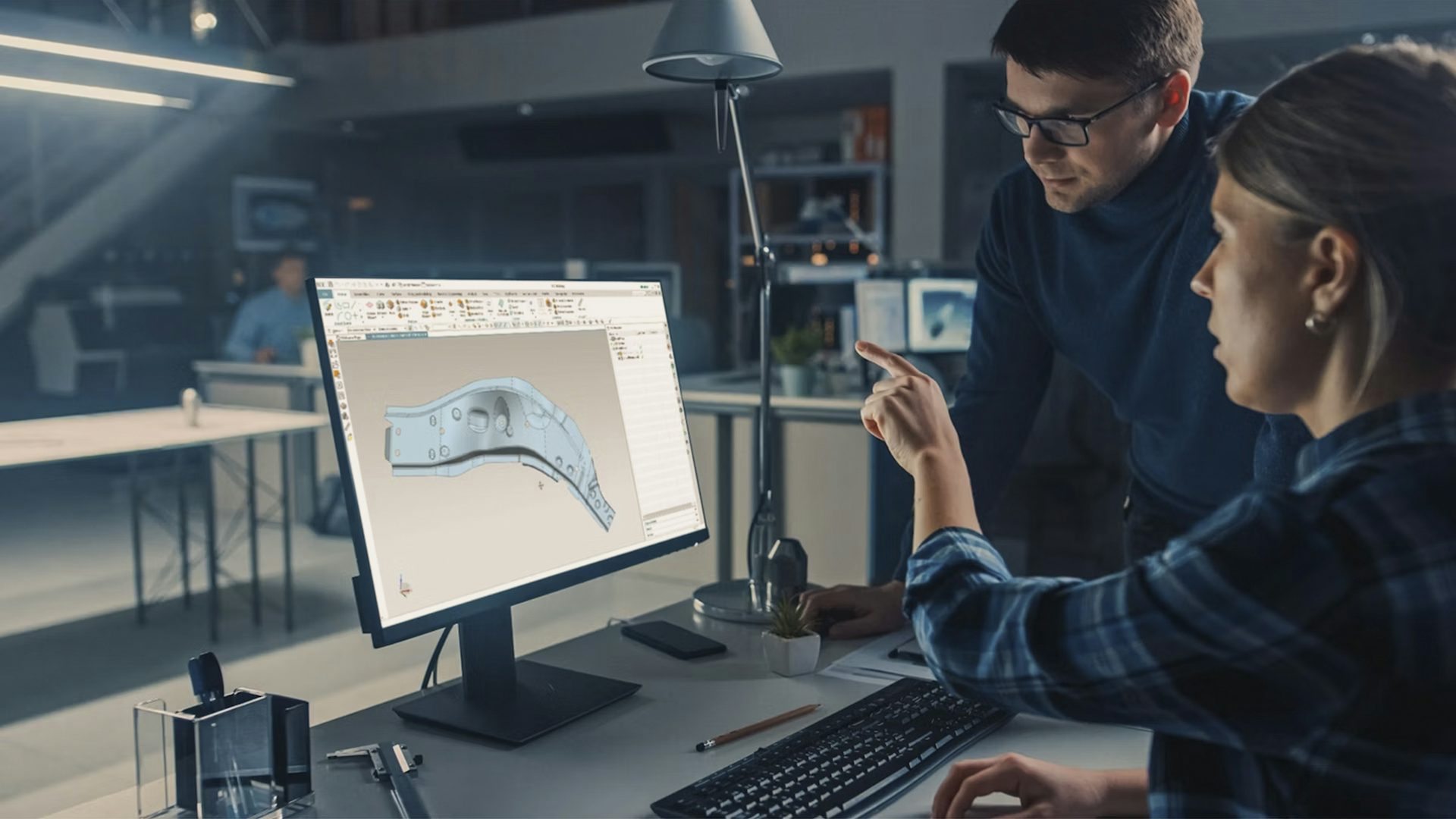

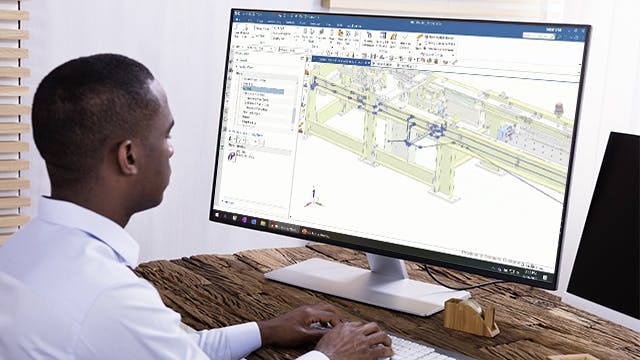

The problem in product design today is that many companies still use disconnected legacy design systems that do not support a holistic next-generation product design approach. To be successful, design must be fully integrated with simulation, validation, manufacturing and the rest of the product development process.

.jpg?auto=format,compress&w=640&q=60)

.jpg?auto=format,compress&w=640&q=60)