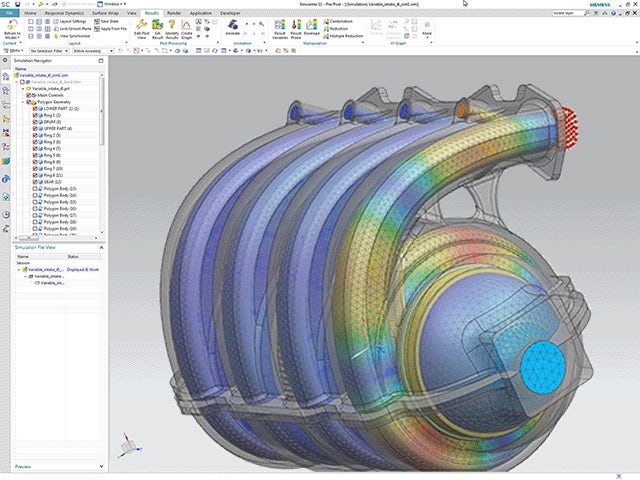

Pochopení a zajištění výkonu napříč doménami vyžaduje řešení simulací a testů, která je možné nasadit ve všech fázích vývoje a ve všech doménách výkonu a fyzice. Kromě toho je třeba tyto aktivity propojit, nikoli provádět nezávisle, aby zachytily multifyzikální jevy reálného světa a vyvážily protichůdné atributy. Simcenter nabízí integrované portfolio nejlepších řešení pro prediktivní simulace, testování a průzkum návrhů ve své třídě, která pokrývají všechny fáze procesu vývoje produktu a řeší nejnáročnější problémy v oblasti inženýrství a pomáhají transformovat projektování tím, že zvyšují produktivitu a podporují inovace.

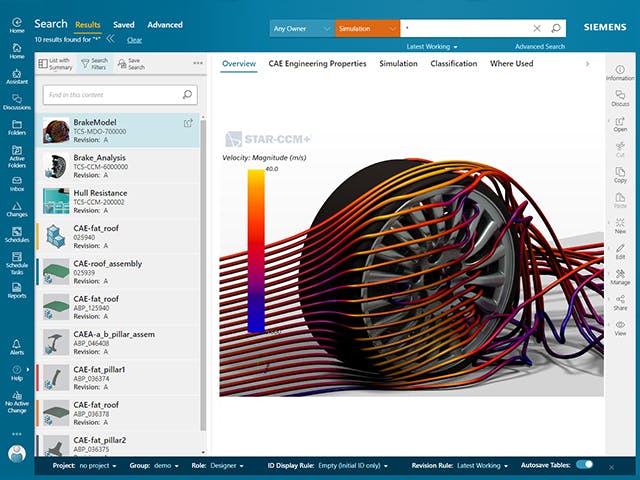

Na simulaci a testování již nelze pohlížet jako na izolované aktivity. Digitální dvojče přináší hodnotu v průběhu celého životního cyklu a jeho vývoj je třeba řídit z hlediska sledovatelnosti a dopadu změn. To je možné pouze poskytováním simulací a testů v rámci celkové iniciativy vývoje digitálních produktů. Siemens Xcelerator stírá hranice mezi inženýrskými oblastmi, jako je elektrotechnika, strojírenství a software, a simulační a testovací řešení Simcenter doplňují řešení Siemens Xcelerator při navrhování, realizaci a optimalizaci fází životního cyklu.

Na cestě k digitální transformaci potřebují společnosti spolehlivé partnery se zdroji, kteří budou neustále podporovat inovace nástrojů a aplikací. Siemens významně investuje do výzkumu a vývoje, využívá partnerství se zavedenými společnostmi v přilehlých oblastech a investuje do startupů, které disponují technologiemi, jež by mohly v budoucnu transformovat podnikání. To vše zajišťuje stálý přísun inovací, které mohou našim zákazníkům pomoci zůstat na špici a realizovat výhody digitalizace rychleji než jejich konkurenti. Inženýrské a konzultační služby Simcenter poskytují hluboké znalosti oboru, zařízení, zdroje a odborné znalosti pro urychlení transformace inženýrských procesů a výsledné návratnosti investic.