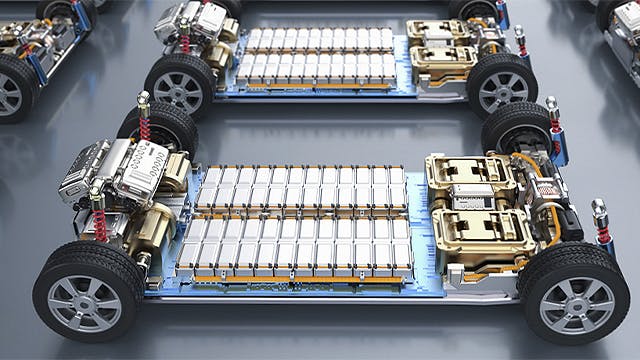

Výkonnost vozidla souvisí s celkovými schopnostmi, účinností a funkčností vozidla a zahrnuje aspekty, jako je zrychlení, dojezd baterie, bezpečnost, aerodynamika a hospodaření s vodou, pokročilé asistenční systémy řidiče (ADAS), řízení energie a teploty, hluk, vibrace a drsnost (NVH) a akustika, pevnost a odolnost, ovládání vozidla a ovladatelnost vozidla.

Výkonnostní inženýrství v automobilovém průmyslu se řídí obchodními požadavky a poskytuje komplexní optimalizaci systému prostřednictvím nepřetržité virtuální testovací a monitorovací smyčky. Výrobci automobilů a dodavatelé se snaží poskytovat lepší obchodní hodnotu tím, že odhalují potenciální problémy v rané fázi vývojového cyklu. Díky simulaci v rané fázi procesu návrhu a virtuálnímu testování, zda produkty splňují požadavky, mohou včas odhalit problémy a napravit je ve srozumitelném digitálním dvojčeti. Kromě toho mohou prozkoumat alternativy návrhu dříve ve fázi návrhu, kdy je změna návrhů jednodušší a méně rušivá.