Comment NX for Manufacturing peut vous aider

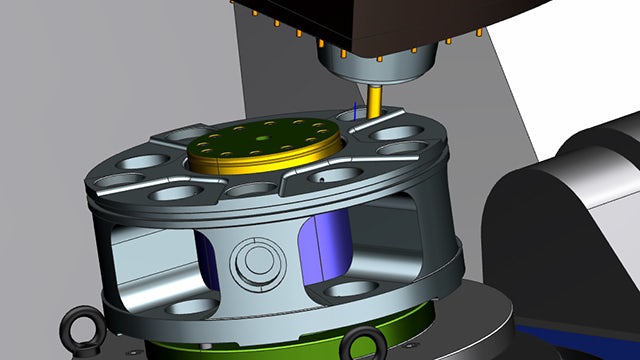

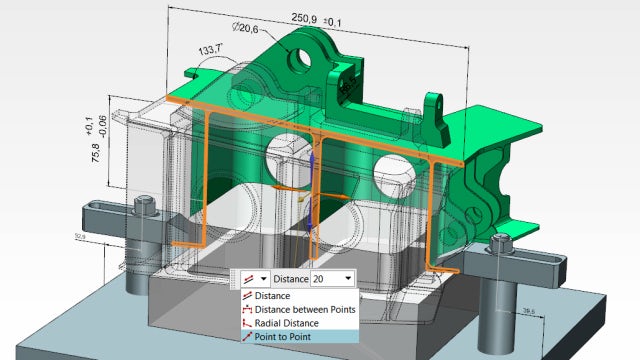

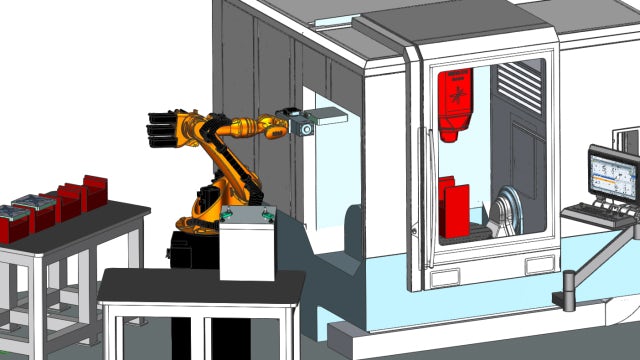

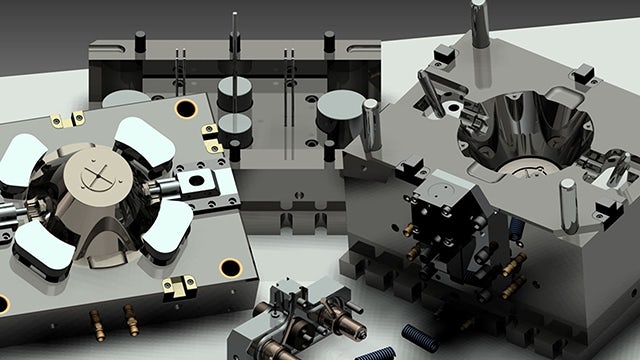

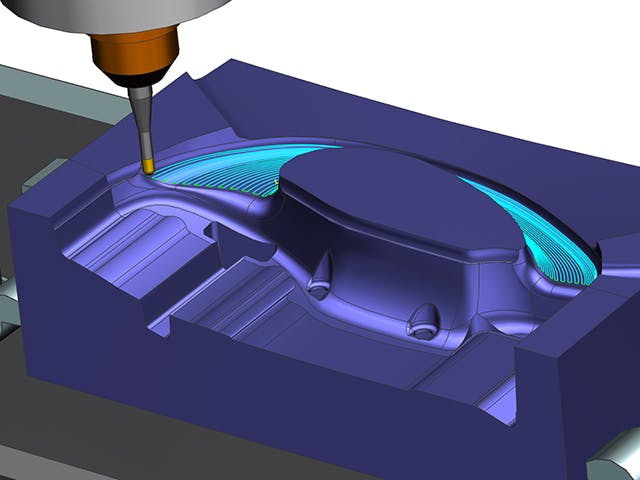

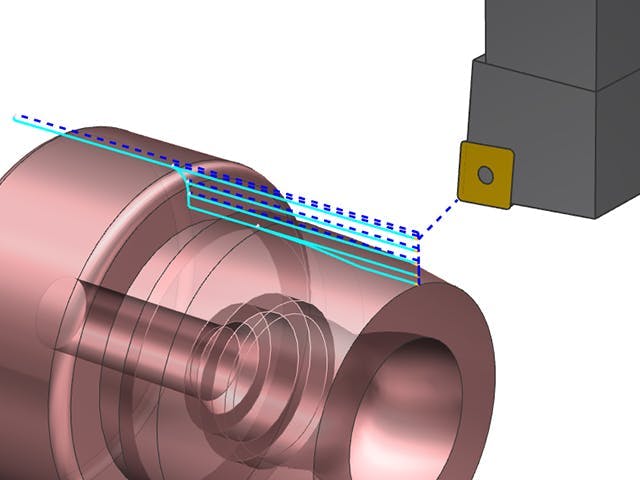

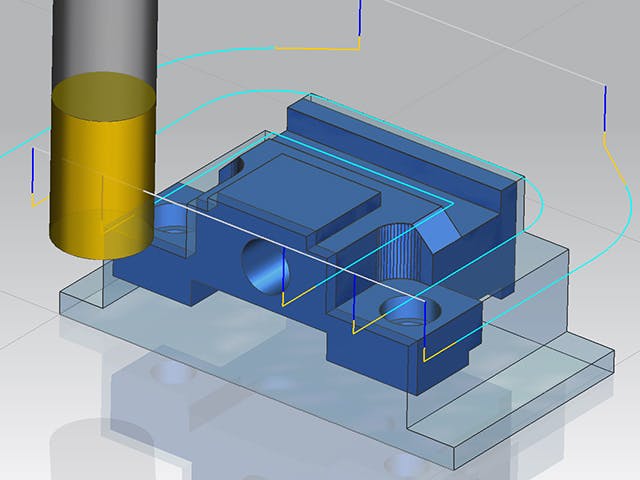

Programmez, simulez et connectez les processus de fabrication de pièces à l'aide d'un système logiciel intégré, y compris l'usinage CNC, la robotique, l'impression 3D et les opérations d'inspection de la qualité.

Explorez les solutions avancées de NX for Manufacturing.

Étude de cas

Lightway

Étude de cas

De la fabrication additive à l’usinage

Société:Lightway

Lieu:Niederzissen, Allemagne

Siemens Software:NX

Explorez les produits NX for Manufacturing

Obtenez plus de détails sur notre large gamme de solutions pour vos besoins spécifiques de fabrication de pièces.

Approfondissez vos connaissances sur NX for Manufacturing

Support client

Siemens offre un support client de classe mondiale pour NX et tous nos produits.

Blog NX Manufacturing

Tenez-vous au courant des actualités et des points forts du logiciel NX for Manufacturing sur notre blog.

Communauté NX Manufacturing

Rejoignez la communauté ou obtenez des réponses à toutes vos questions sur le logiciel NX for Manufacturing.