Motivos por los que utilizar Tecnomatix

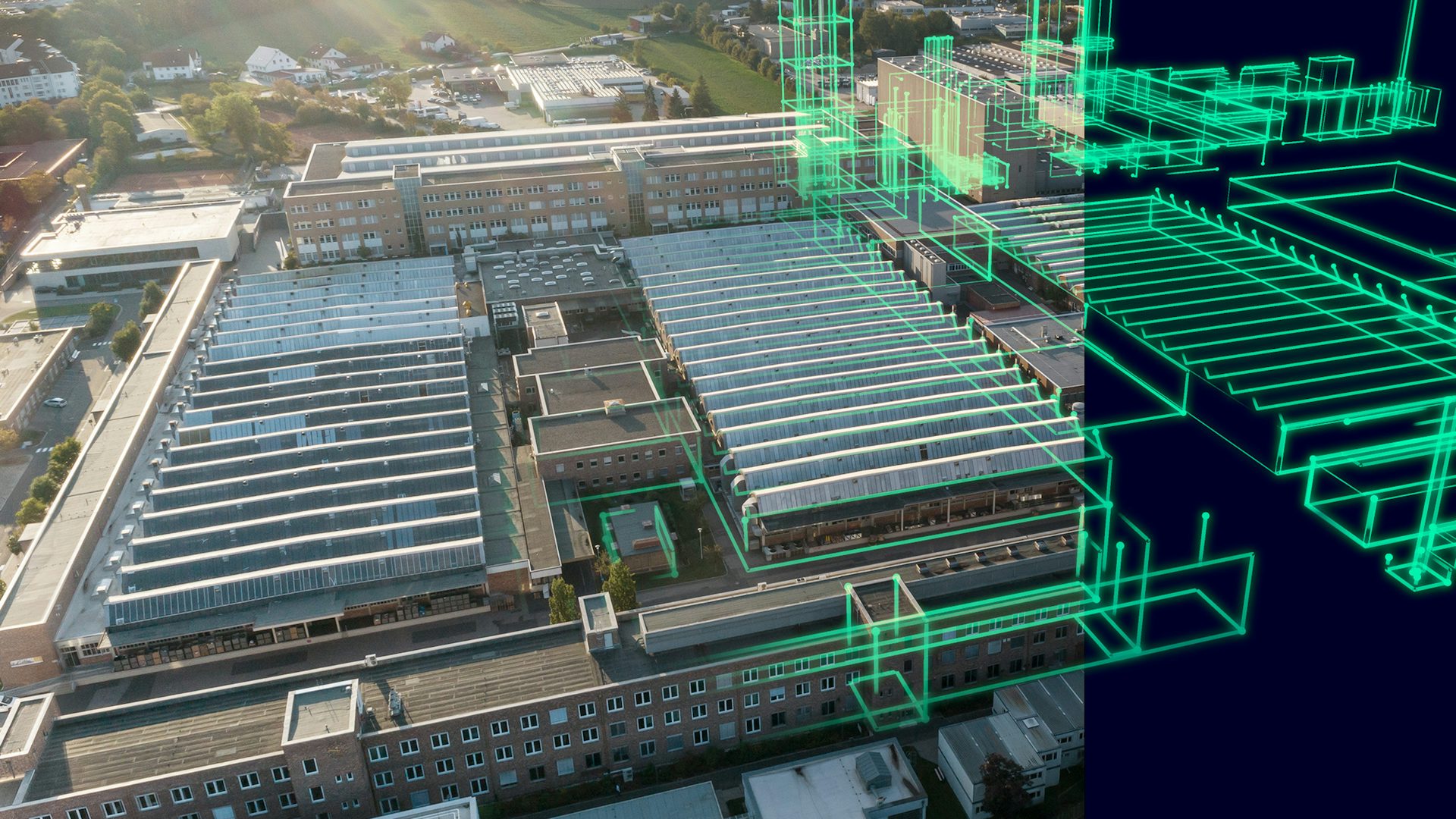

Crea el gemelo digital

Modela, simula y optimiza un gemelo digital completo de tus procesos de fabricación, incluidos robots, automatización, sistemas de manipulación de materiales y personas, para mejorar el rendimiento de tu empresa.

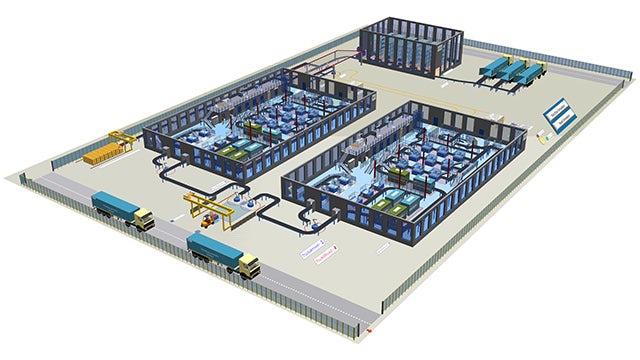

Aumenta la flexibilidad

Utiliza la simulación y la optimización de procesos de producción automatizados o manuales para evaluar e implementar avanzadas técnicas de fabricación, equipos y operaciones y lograr una fabricación más flexible.

Innova más deprisa

Utiliza un entorno realista e inmersivo de alta fidelidad con herramientas de modelado, simulación y optimización basadas en física para acelerar la innovación.

Fabricación centrada en el ser humano

¿Qué nos lleva al fondo del océano y al espacio exterior? ¿Qué nos mantiene seguros y conectados? La fabricación centrada en el ser humano,

que te ayuda hoy a convertir las innovaciones del mañana en productos transformadores. Mediante tecnologías de vanguardia como la robótica avanzada y la inteligencia artificial, convierte en realidad las fábricas autoorganizadas. Echa un vistazo a la fabricación del mañana.

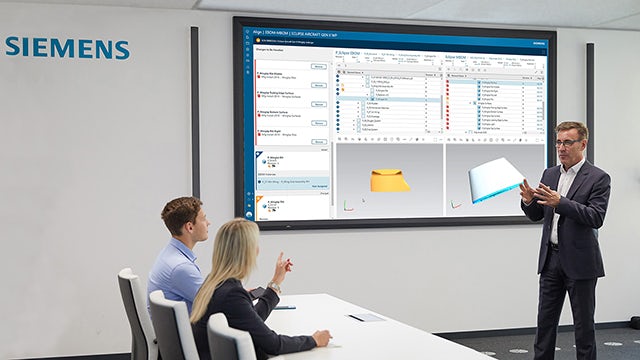

Explorar funcionalidades de Tecnomatix

Aprovecha la fabricación digital para mejorar tus negocios ahora y mantenerlos en el futuro.

Obtén información sobre las últimas novedades en el blog de Tecnomatix

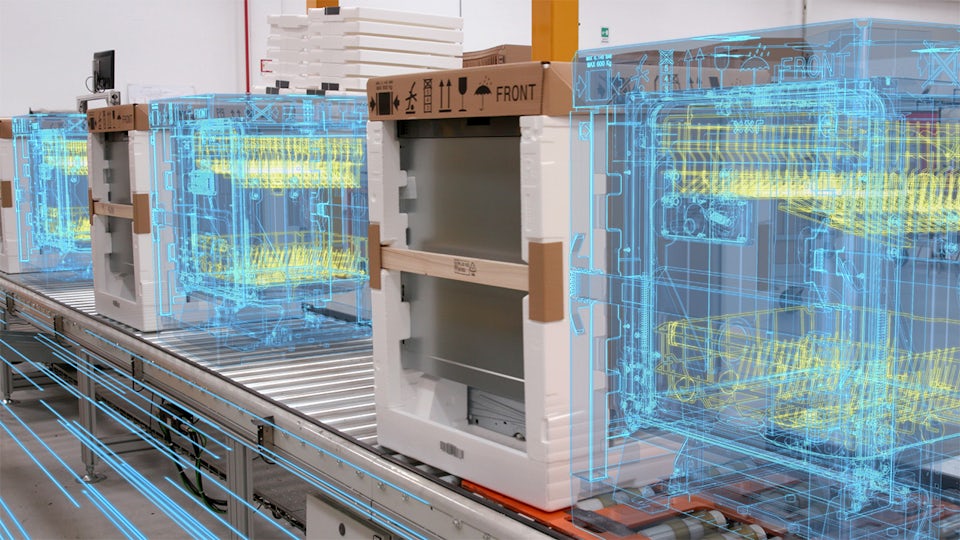

Electrolux

Teamcenter, Simcenter and Tecnomatix help reduce development time by 20 to 30 percent

Empresa:Electrolux

Industria:Productos de consumo y comercio minorista

Ubicación:Stockholm, Sweden

Software de Siemens:Simcenter 3D Solutions, Teamcenter, Tecnomatix

Explorar grupos de productos de software Tecnomatix

Optimiza tus procesos y equipos de fabricación utilizando productos de software de fabricación digital.