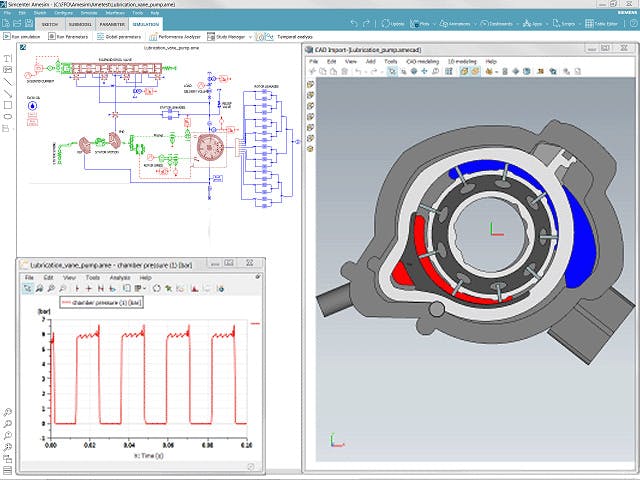

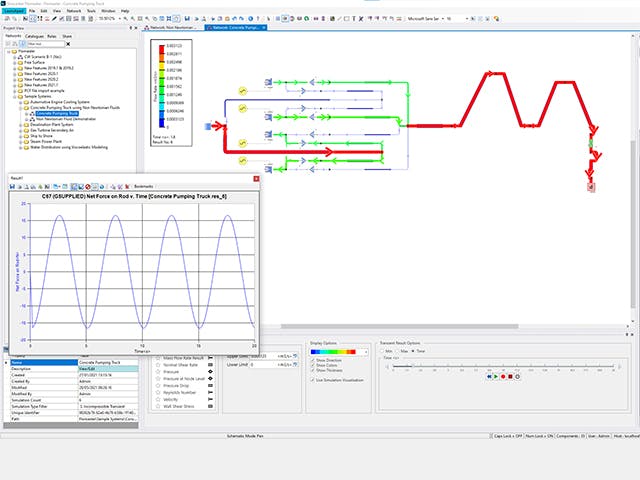

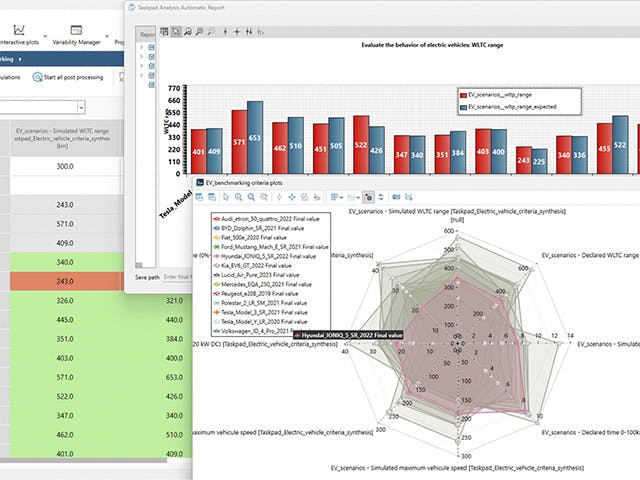

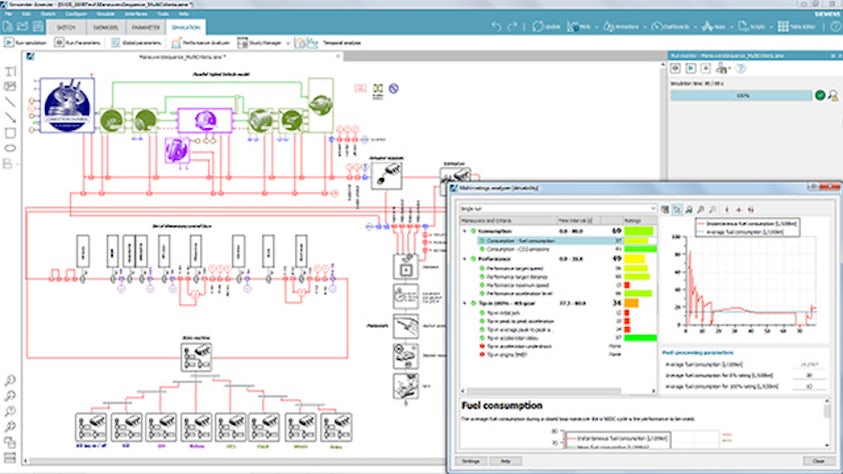

Simcenter Systems offers state-of-the-art, open and user-friendly multiphysics system simulation platforms to model, run and analyze complex systems and components. The powerful features, analysis and optimization tools are embedded in advanced and easy-to-use environments for highly efficient 1D multiphysics system simulation and robust design. It efficiently interfaces with many 1D and 3D computer-aided engineering (CAE) software solutions and helps you quickly derive and export models for standard real-time targets by providing a consistent and continuous model-in-the-loop (MiL), software-in-the-loop (SiL) and hardware-in-the-loop (HiL) capable framework.