How NX for manufacturing can help you

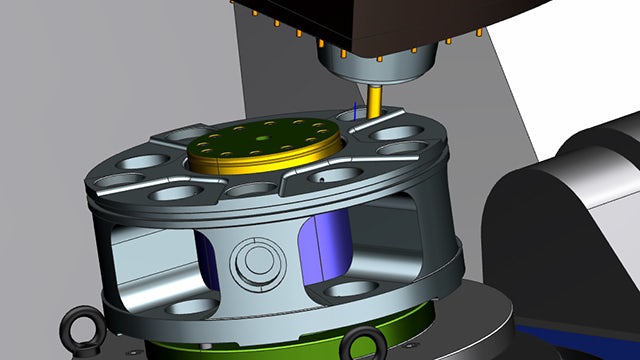

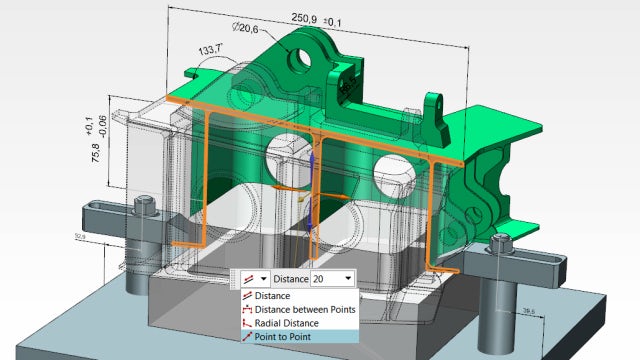

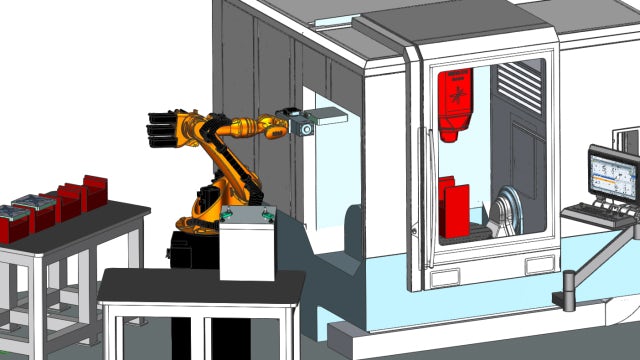

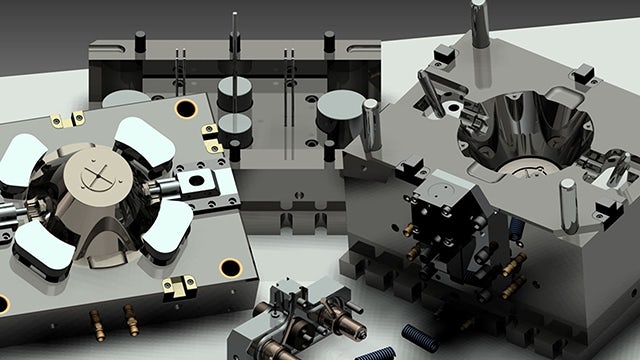

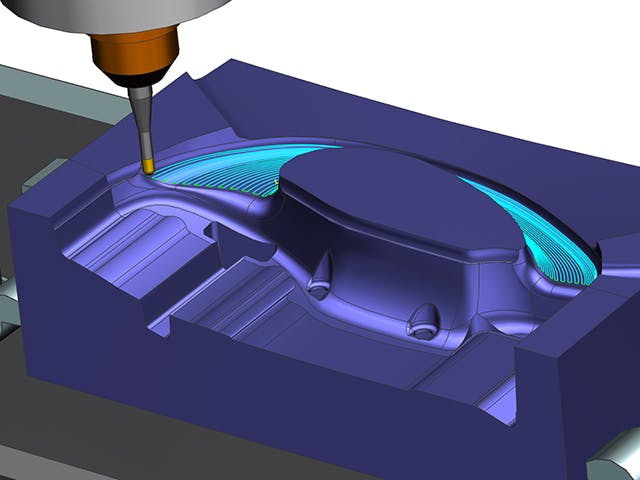

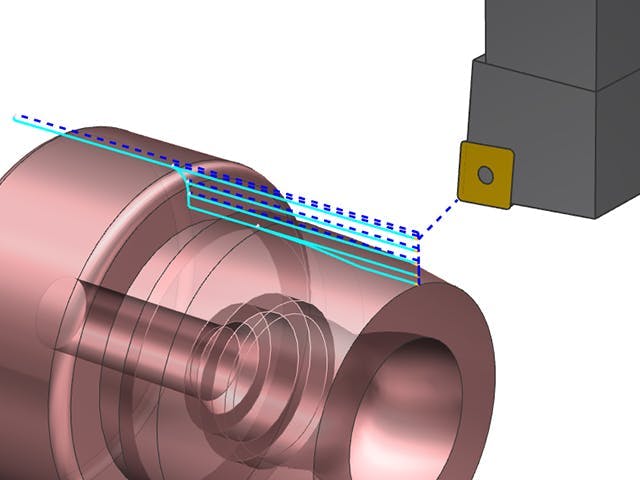

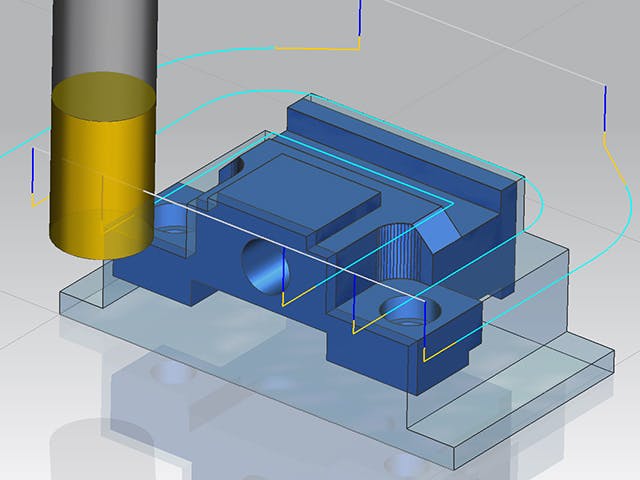

Program, simulate and connect part manufacturing processes using an integrated software system, including CNC machining, robotics, 3D printing and quality inspection operations.

Explore NX for manufacturing advanced solutions.

Case study

Lightway

Case study

From additive manufacturing to machining

Company:Lightway

Location:Niederzissen, Germany

Siemens Software:NX

Explore NX for manufacturing products

Get more details about our wide range of solutions for your specific part manufacturing needs.

Deepen your NX for manufacturing knowledge

Customer support

Siemens offers world-class customer support for NX and all of our products.

NX manufacturing blog

Keep up with the latest news and highlights of NX for manufacturing software on our blog site.

NX manufacturing community

Join the conversation or get answers to all of your NX for manufacturing software questions.