Powerful, flexible CAD for start ups to global enterprises

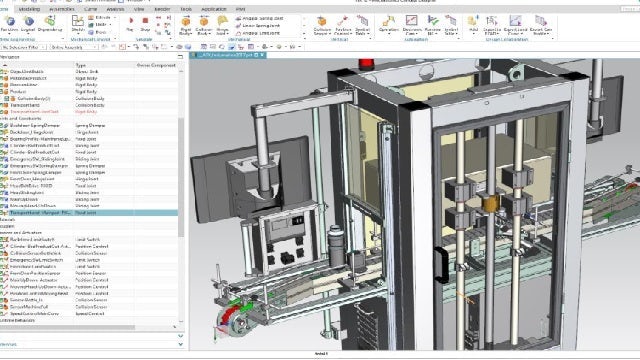

Developed for product designers of all experience levels, NX CAD delivers unparalleled power to:

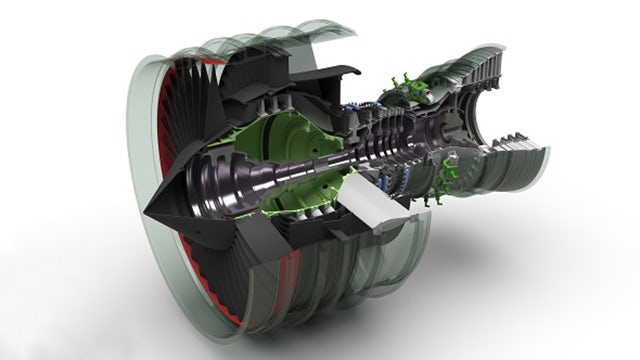

- Create illustrations and 3D models

- Analyze product design feasibility for errors before moving to manufacturing

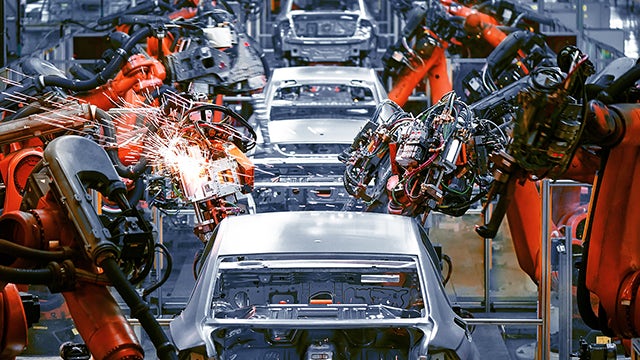

- Seamlessly share data to foster collaboration and accelerate production cycles

NX CAD scales with your growth, with three tiers of pre-packaged NX X Design solutions that deliver the precise design power your team needs.