Why Tecnomatix?

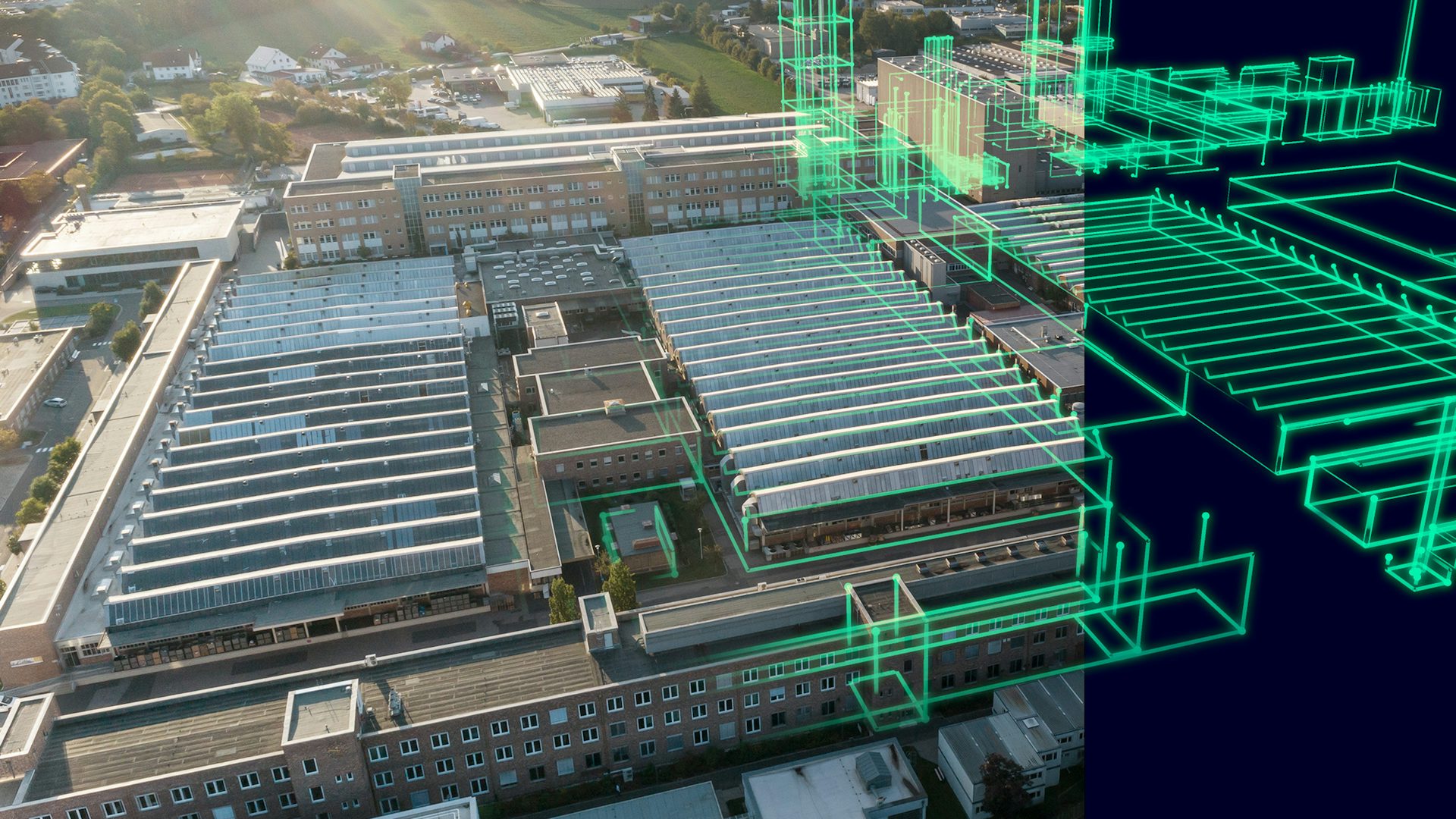

Build the digital twin

Model, simulate and optimize a comprehensive digital twin of your manufacturing processes—including robots, automation, material handling systems and people—to improve the performance of your business.

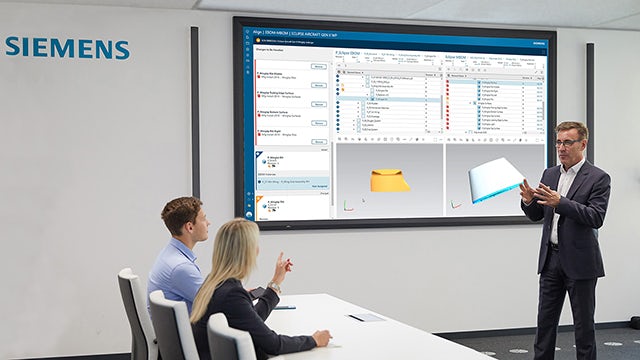

Increase flexibility

Use simulation and optimization for automated or manual production processes to evaluate and implement advanced manufacturing techniques, equipment and operations for more flexible manufacturing.

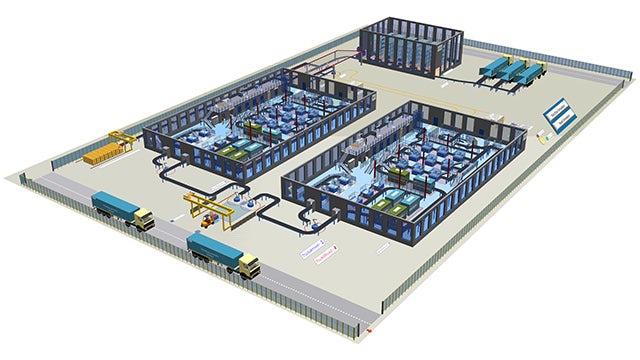

Innovate faster

Use a realistic and immersive, high-fidelity environment with physics-based modeling, simulation and optimization tools to speed your innovation.

Human-centered manufacturing

What gets us to the bottom of the ocean and into outer space? What keeps us safe and connected? Human-centered manufacturing.

Human-centered manufacturing helps you turn tomorrow’s innovations into transformative products, today. Using breakthrough technologies such as advanced robotics and artificial intelligence, it makes self-organizing factories a reality. Get a glimpse into tomorrow's manufacturing.

Explore Tecnomatix capabilities

Leverage digital manufacturing to improve your business now and sustain it for the future.

Get the latest news on the Tecnomatix blog

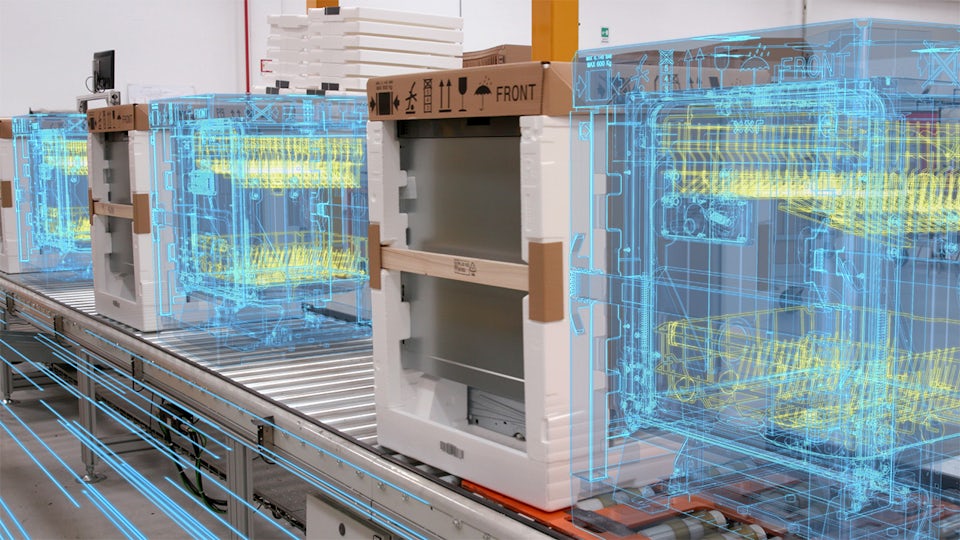

Electrolux

Teamcenter, Simcenter and Tecnomatix help reduce development time by 20 to 30 percent

Company:Electrolux

Industry:Consumer products & retail

Location:Stockholm, Sweden

Siemens Software:Simcenter 3D Solutions, Teamcenter, Tecnomatix

Explore Tecnomatix software product groups

Get the most out of your manufacturing processes and equipment using digital manufacturing software products.