PLM Components

Reduce the cost and risk of delivering 3D software innovation to your customers and increase the value of your applications in design, simulation, manufacturing, collaboration and visualization by joining hundreds of software vendors who choose PLM Components.

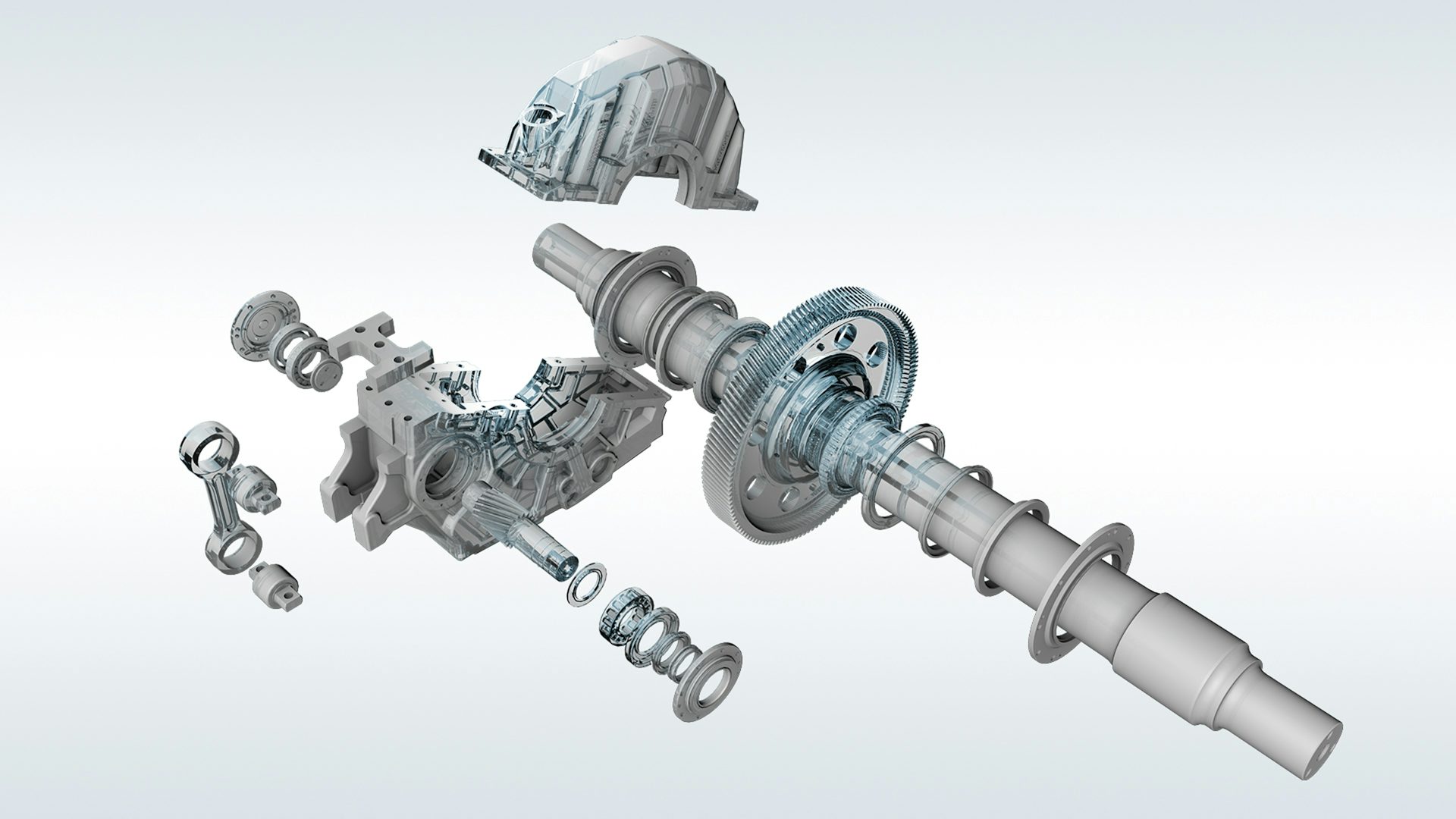

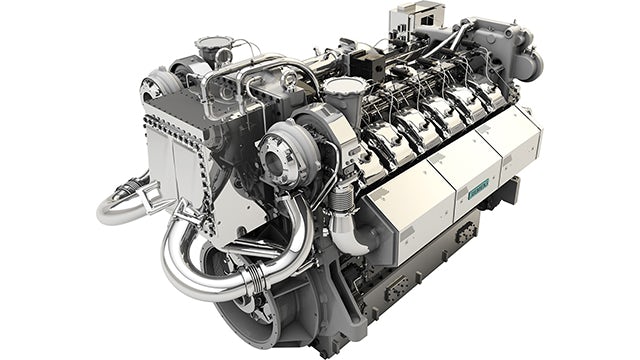

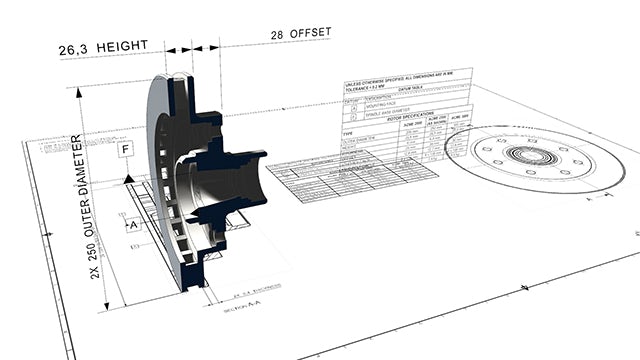

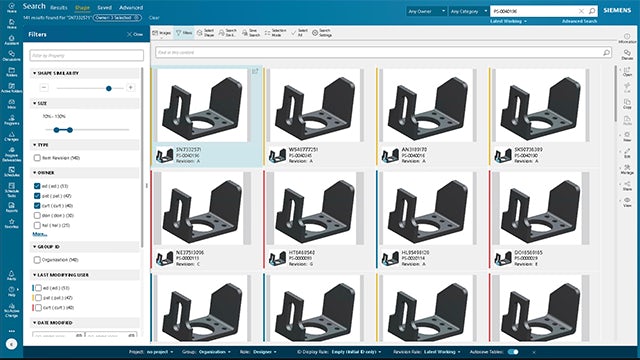

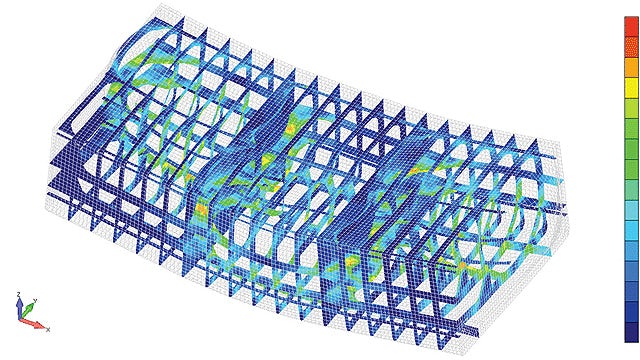

Our leading solutions for geometric modeling, digital manufacturing, simulation, visualization and data exchange have a proven history of continuous innovation, industry-tested quality and consistent high performance.

Licensing our 3D software developer toolkits to build a new software application—rather than reinventing the wheel with a proprietary solution—is often an easy decision. For more established software applications, switching to an alternative solution for innovative design, manufacturing or simulation capabilities may require more careful consideration.

With a broad set of benefits that we've consistently demonstrated over decades, licensing our solutions is an attractive option for both new and established 3D software development companies.

PLM Components market leadership

Join a growing ecosystem of software vendors and end-users who choose PLM Components for their software applications in computer-aided design (CAD), computer-aided manufacturing (CAM) and computer-aided engineering (CAE).

software vendors integrate PLM Components into their commercial applications for 3D product design, manufacturing and simulation.

software end-users benefit from applications that adopt PLM Components and share 3D data using our standard JT and Parasolid data file formats.

estimated market penetration of PLM Components across major design, manufacturing and simulation solutions according to a leading industry analyst.

Build with PLM Components

Stay connected with PLM Components

Read the blog

Gain new perspectives on PLM Components and the PLM market in general.