Handle more options with less effort

Use a single definition of variability from product planning to manufacturing and service.

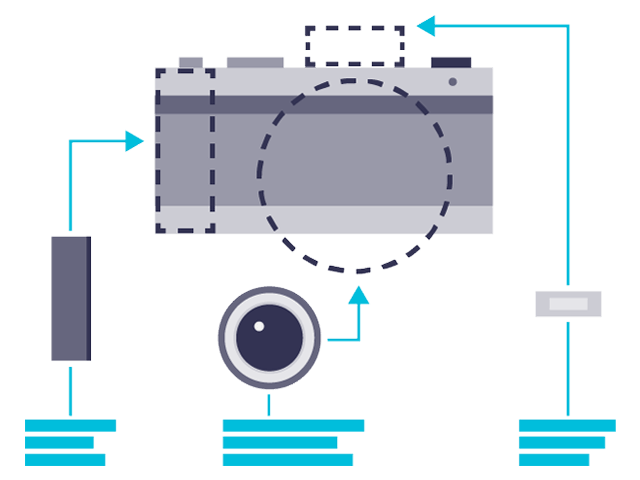

Take control with early feature planning

Leverage a common product definition, so your engineers focus on only valid configurations while manufacturing generates a bill of process (BOP). Be enabled to close the loop on requirements by checking validation rules before production to avoid costly downstream issues during ERP or order management.

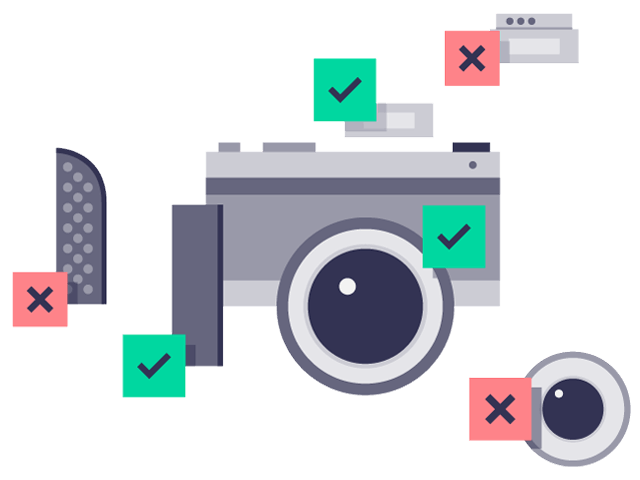

Coordinate your lifecycle

Use multi-domain frameworks to create consistent definitions of product features and families. Promote the widespread reuse of constraints and configuration concepts across software, electrical and mechanical domains. This reduces discrepancies whether you're configuring for design, engineering, manufacturing or sales.

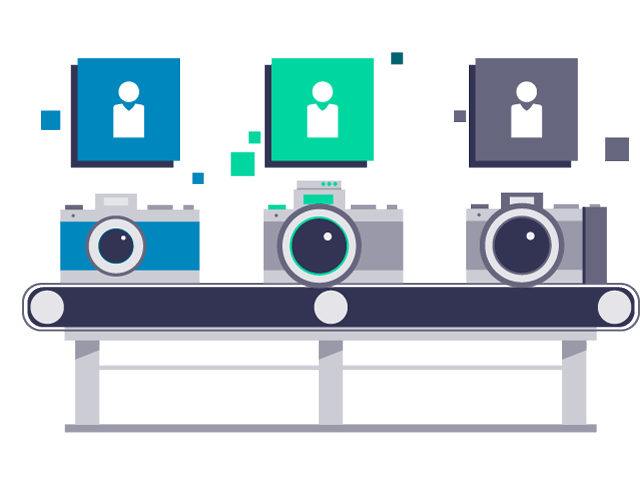

Empower consumer choice with engineering automation

Automate product and process data generation with engineer-to-order capabilities in Rulestream and Teamcenter. Address new requirements quickly and accurately while ensuring that you meet organizational constraints. Create bid and manufacturing packages in minutes rather than weeks. Support customer demands for engineer-to-order products while maintaining profitability.

Custom Engineer to Order Solutions Configured Faster

Learn how Mitsubishi Heavy Industries Compressor International Maximizes its engineer to order efficiency with Rulestream.

Konecranes

Konecranes manages custom lift products

Company:Konecranes

Location:Hyvinkää, Finland

Siemens Software:Teamcenter