A complete design-to-manufacturing solution

Scalable NX CAD/CAM (computer aided-design/manufacturing) software empower startups, mid-size and multinational corporations to gain a competitive advantage in their markets.

Help your teams collaborate more effectively and deliver innovative, high-quality products faster—with unparalleled precision—using NX CAD and NX CAM solutions.

The NX CAD/CAM advantage

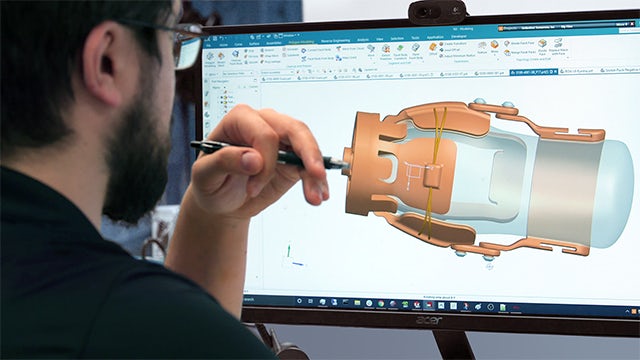

Faster product design cycles

Create high-quality new products with less rework and fewer prototypes using NX CAD.

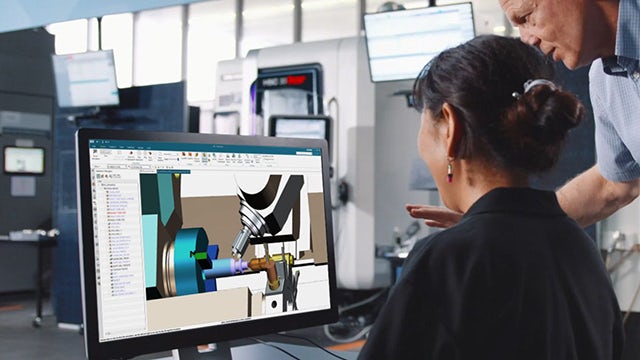

Shorter time-to-delivery

Meet tight deadlines with NX integrated design and manufacturing capabilities.

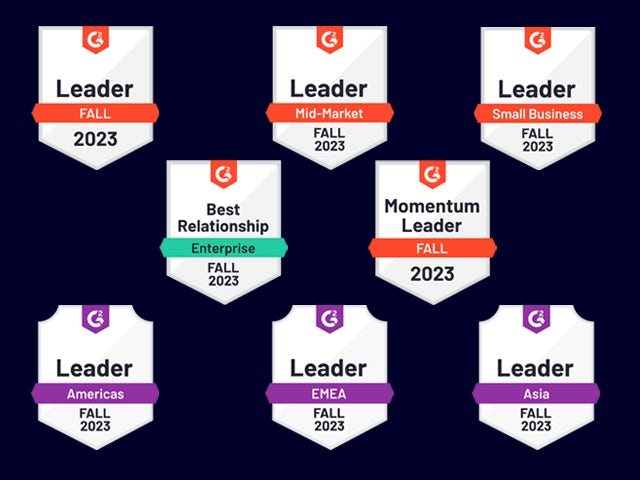

A proven, trusted leader in CAD/CAM

Learn why the NX experience goes beyond powerful software. We're here to support your success each step of the way,

On G2, the independent peer review site, NX consistently receives high marks for:

- Ease of use

- Flexibility

- Quality support

- Customization

- Integrated simulation

See NX CAD reviews | See NX CAM reviews

Excellent user interface, tutorials and manuals

Assistant Professor of Computational Mechanics, Enterprise Customer

Versatility and manageability, NX CAM is the best.

Mechanical Engineer, Small Business Customer

Haidlmair

Haidlmair uses NX to optimize the mold design process

Company:Haidlmair

Location:Nussbach, Austria

Siemens Software:NX

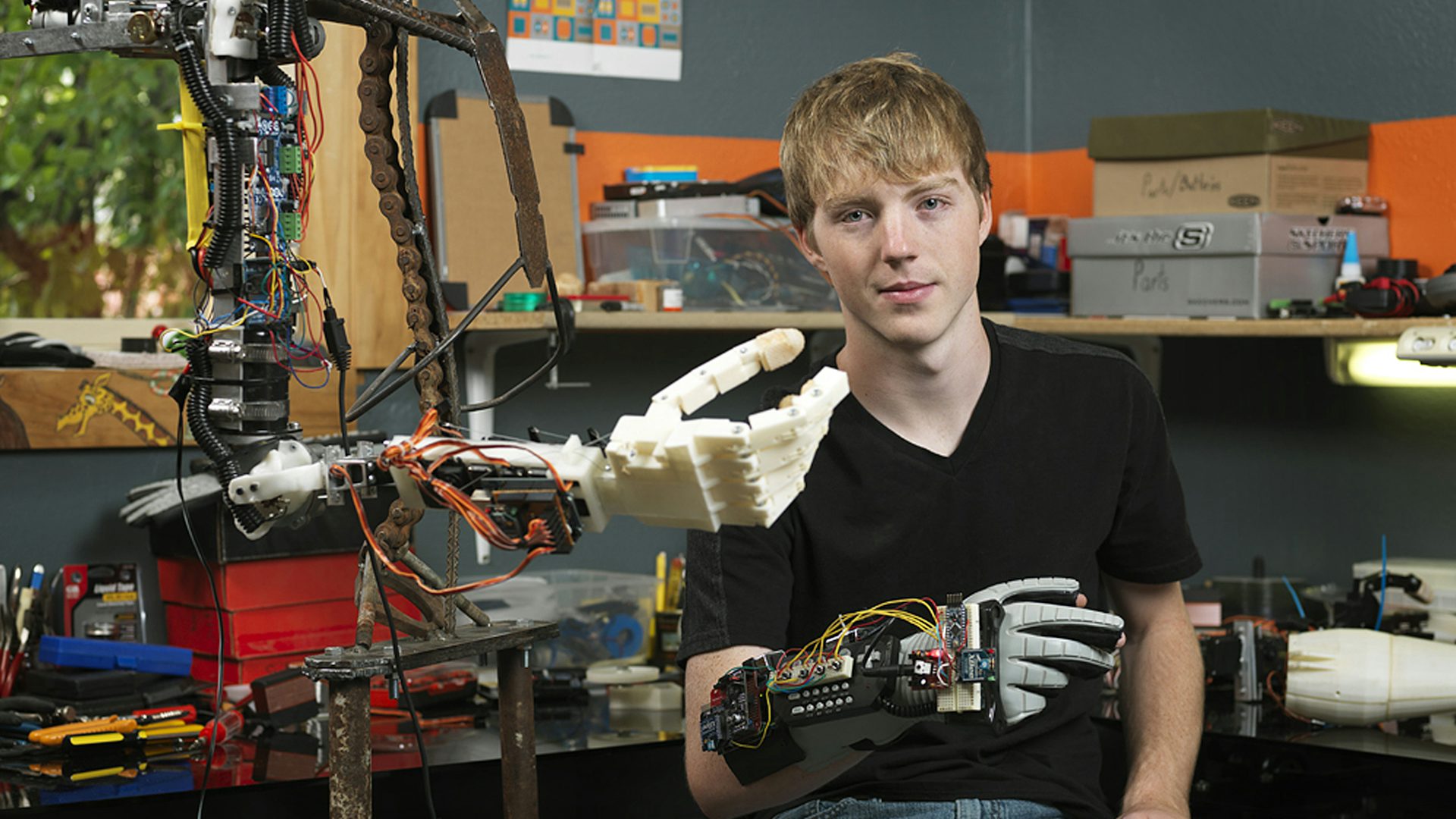

See how NX CAD/CAM software can scale with you

Only Siemens' NX, the integrated software for design and manufacturing, can empower businesses of all sizes to harness the power of the digital twin.

See how NX enables small shops to thrive and large multinationals to sustain their competitive edge.