Why Simcenter?

Double your productivity with our world-class tools – let's engineer innovation with Simcenter.

Model the complexity

Innovation is complex. Predict behavior, enhance accuracy and be confident in early-stage designs. Use performance-based systems engineering to view the entire product lifecycle from component concept to final operational use.

Explore the possibilities

Leverage complex models to fully explore the design space. Save time and gain insight into the digital world before committing to the final design. Discover new designs, optimize performance and improve robustness faster.

Go faster

Use engineering driven by artificial intelligence (AI) to quickly respond to changes in customer preferences. Use scalable, cloud-based processes and the latest automated workflows.

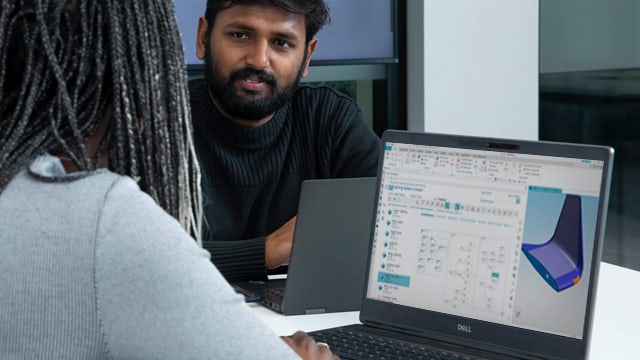

Stay integrated

Connect it all. Link all processes and align teams in the most complex development environments. Balance performance and guarantee traceability with a digital thread that integrates, from simulation models to product data.

Simulation and test solutions

Performance engineering requires accurate prediction to ensure your product delivers. Turn product complexity into a competitive advantage with Simcenter solutions that empower your engineering teams to push the boundaries, solve the toughest problems, and bring innovations to market faster.